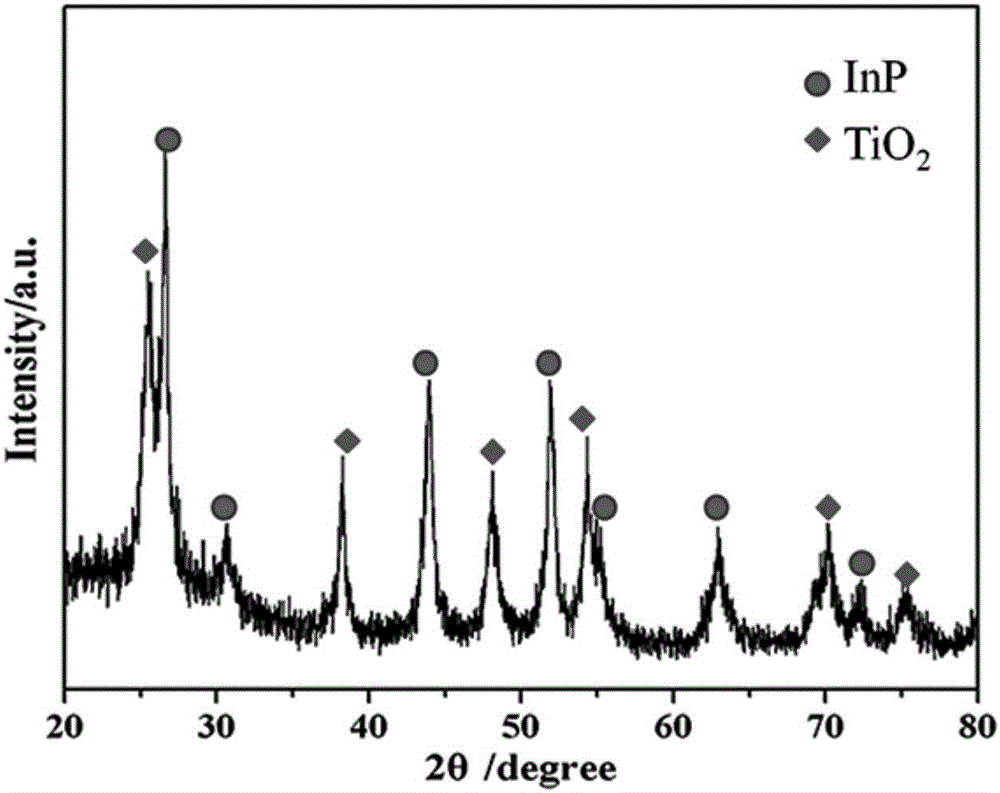

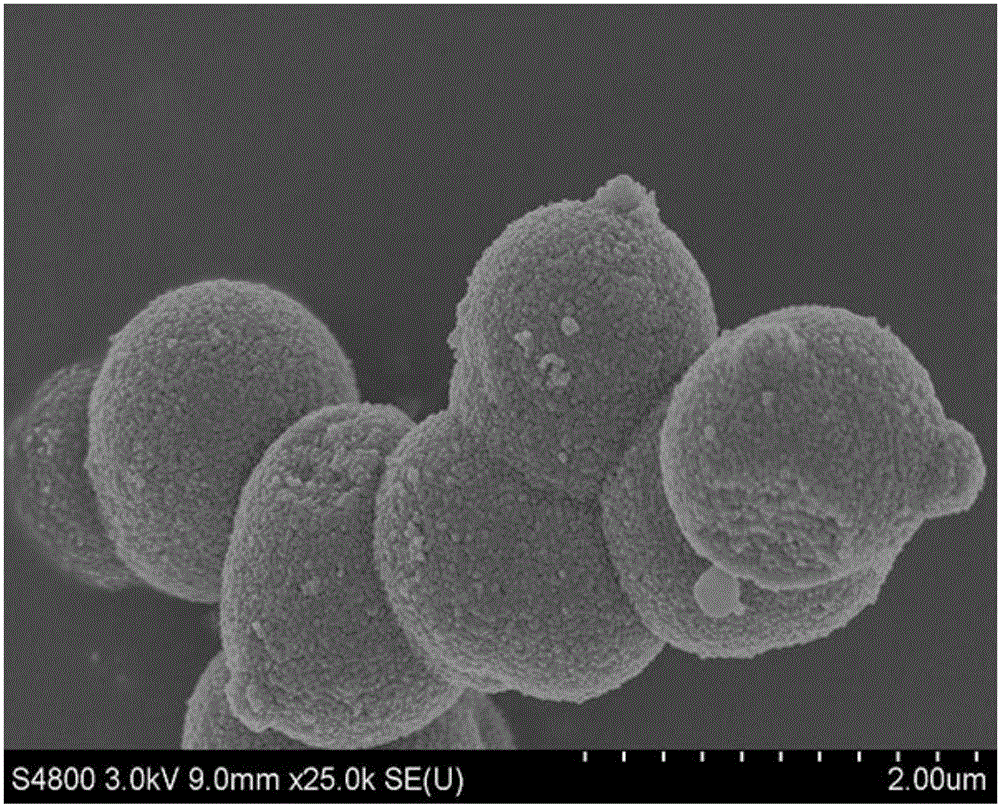

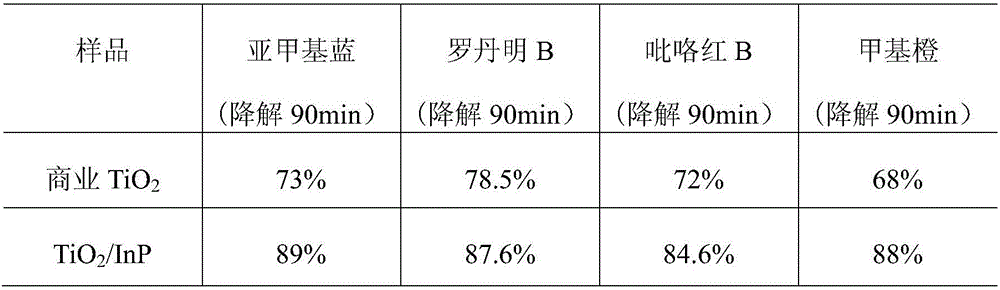

Preparing method and application of titanium dioxide/indium phosphide composite

A composite material and titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., to achieve good degradation effect, high repetition rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the titanium dioxide / indium phosphide composite material of the present embodiment is carried out according to the following steps:

[0029] 1) Dissolution and complexation of indium salt: Accurately weigh 1 mmol of indium chloride (InCl 3 ) was dissolved in a beaker filled with 10mL of deionized water, placed on a magnetic stirrer, stirred vigorously for 10min to fully dissolve, then added 5mL of diethylenetriamine (DETA) for complexation reaction, and continued to stir for 10min until the reaction completely;

[0030] 2) Adding of reducing agent: accurately weigh 4mmol potassium borohydride (KBH 4 ) or sodium borohydride is added in the above-mentioned solution, and magnetic stirring is continued, at this moment, a large amount of bubbles are released, and the solution changes from milky white to lead gray before;

[0031] 3) Addition of titanium salt: after the solution has no bubbles, accurately weigh 4 mmol of titanium sulfate (Ti(SO 4 ...

Embodiment 2

[0037] The preparation method of the titanium dioxide / indium phosphide composite material of the present embodiment is carried out according to the following steps:

[0038] 1) Dissolution and complexation of indium salt: Accurately weigh 1 mmol of indium chloride (InCl 3 ) was dissolved in a beaker containing 10 mL of deionized water, placed on a magnetic stirrer, stirred vigorously for 10 minutes to fully dissolve, then added 5 mL of diethylenetriamine (DETA), and continued to stir;

[0039] 2) Adding of reducing agent: accurately weigh 4mmol potassium borohydride (KBH 4 ) or sodium borohydride is added in the above-mentioned solution, and magnetic stirring is continued, at this moment, a large amount of bubbles are released, and the solution changes from milky white to lead gray before;

[0040] 3) Addition of titanium salt: after the solution has no bubbles, accurately weigh 4 mmol of titanium sulfate (Ti(SO 4 ) 2 ), added in the above solution, and continued to stir fo...

Embodiment 3

[0046] The preparation method of the titanium dioxide / indium phosphide composite material of the present embodiment is carried out according to the following steps:

[0047] 1) Dissolution and complexation of indium salt: Accurately weigh 1 mmol of indium chloride (InCl 3 ) was dissolved in a beaker containing 10 mL of deionized water, placed on a magnetic stirrer, stirred vigorously for 10 min to fully dissolve, then added 5 mL of diethylenetriamine (DETA), and continued to stir for 10 min;

[0048] 2) Adding of reducing agent: accurately weigh 4mmol potassium borohydride (KBH 4 ) or sodium borohydride is added in the above-mentioned solution, and magnetic stirring is continued, at this moment, a large amount of bubbles are released, and the solution changes from milky white to lead gray before;

[0049] 3) Addition of titanium salt: after the solution has no bubbles, accurately weigh 4 mmol of titanium sulfate (Ti(SO 4 ) 2 ), add in the above-mentioned solution, continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com