Low-basicity superfine activated calcium carbonate and preparation method thereof

An active calcium carbonate, low alkalinity technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of difficult to obtain regular crystal shape and dispersibility, difficult to control the pH point of aging, complicated operation process, etc., to achieve high performance and added value, regular crystal shape, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

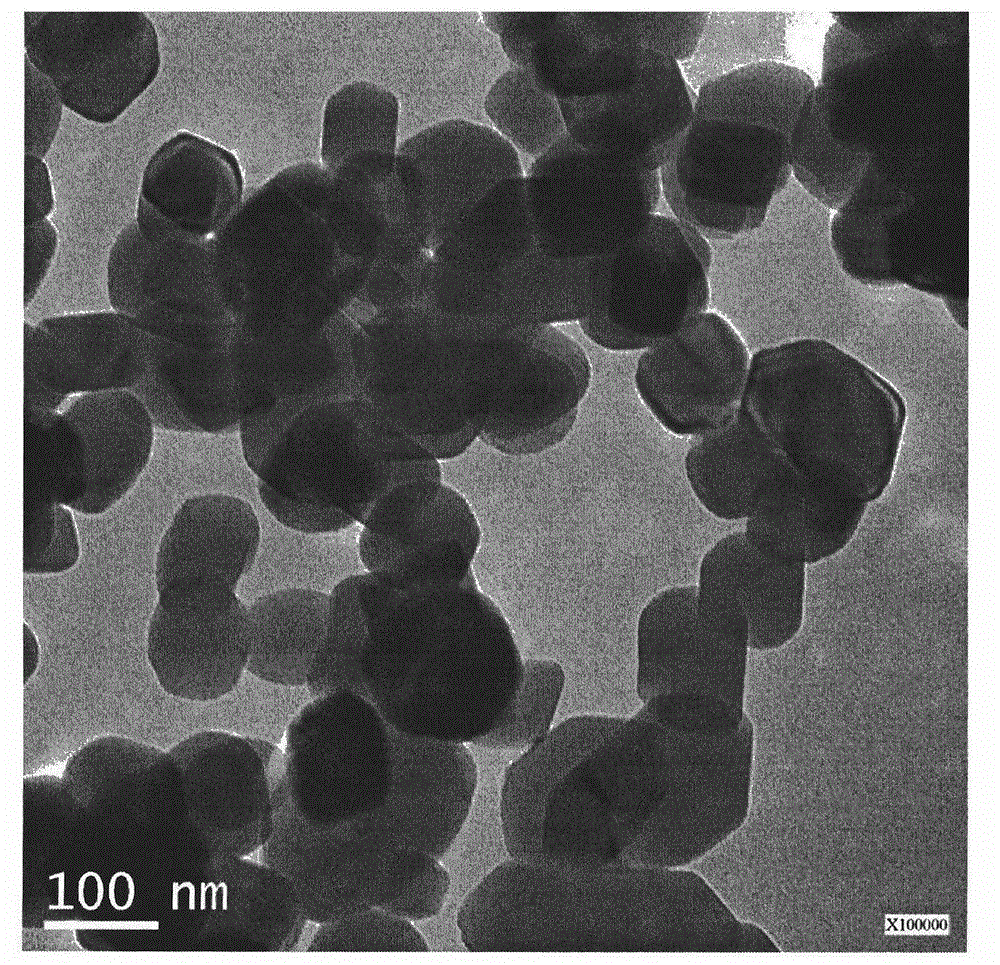

[0032] In a 10L reactor, add 8L milk of lime with a calcium hydroxide mass percentage concentration of 12wt%, when the temperature is 37°C, add 8.0g glucose and 24.0g calcium chloride respectively, and pass in carbon dioxide with a concentration of 50% under mechanical stirring (volume fraction) gas, carry out carbonization reaction, gas flow rate is 230L / h, when carbonization to system pH is 6.7, stop ventilating, after being warming up to 70 ℃, adding concentration is 12wt% sodium stearate emulsion 167ml, coating Activate for 2 hours, then filter while hot, and dry the filter cake at 100°C to obtain cubic superfine calcium carbonate powder. The product has a regular shape, a particle size distribution of 80-100nm, and a specific surface area of 19.8m 2 / g, the pH value of the powder is 8.2, and there is no agglomeration phenomenon, see figure 1 .

Embodiment 2

[0034] In a 10L reactor, add 8L calcium hydroxide mass percent concentration and be 15wt% milk of lime, when temperature is 30 ℃, add 1.01g sucrose and 1.07g glucose and 5.20g magnesium chloride respectively, feed carbon dioxide concentration under mechanical stirring. The gas of 36% (volume fraction) carries out carbonization reaction, and gas flow rate is 300L / h, and when carbonization system is to pH 6.5, stop ventilating, be warming up to 80 ℃, add concentration and be 140ml of potassium stearate emulsion of 15wt%, Coating and activating treatment for 1.5h, then filtering while hot, and drying the filter cake at 100°C to obtain cubic ultrafine calcium carbonate powder. The product has a regular appearance, a particle size distribution of 90-120nm, and a specific surface area of 17.3m 2 / g, the pH value of the powder is 8.4, and there is no agglomeration phenomenon.

Embodiment 3

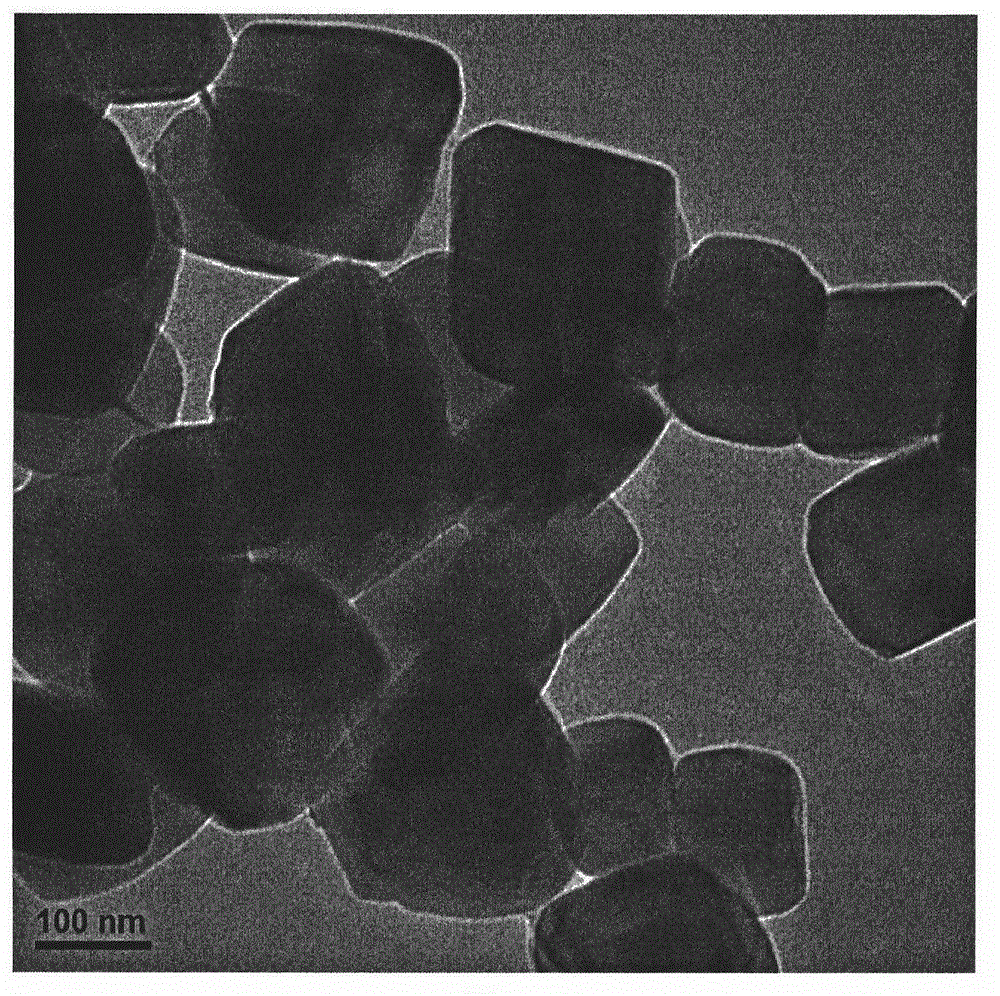

[0036] In a 10L reactor, add 8L of milk of lime with a mass percent concentration of calcium hydroxide of 8wt%. When the temperature is 35°C, add 5.76g of sodium citrate and 24.0g of calcium nitrate, and feed in carbon dioxide with a concentration of 25% under mechanical stirring. % (volume fraction) gas, carry out carbonization reaction, gas flow rate is 160L / h, when carbonization to pH is 6.6, stop ventilating, be warming up to 85 ℃, add concentration and be 5wt% sodium abietate emulsion 145ml, coating activation Treat for 1.5h, then filter while hot, and dry the filter cake at 100°C to obtain cubic superfine calcium carbonate powder. The product has a regular shape, a particle size distribution of 100-140nm, a powder pH of 8.1, and a specific surface area of 12.3m 2 / g, and no agglomeration, see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com