Environmental-protection and energy-saving waterproof heat insulation material and preparation method thereof

A heat insulation material and energy-saving technology, applied in the field of building materials, can solve the problems of affecting waterproof and heat insulation performance, easy water seepage, high cost of protective layer, etc., achieves obvious heat insulation effect, high proportion of active ingredients, and excellent product stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 An environmentally friendly and energy-saving waterproof and heat-insulating material, which is made of the following raw materials in parts by weight:

[0027] 2 parts of redispersible latex powder, 6 parts of mica powder, 20 parts of heavy calcium powder, 25 parts of stone, 10 parts of quartz sand, 0.5 part of hydroxypropyl methylcellulose, 0.1 part of polycarboxylate superplasticizer, silyl 0.1 part of powder, 0.2 part of polypropylene short fiber, 36.1 part of white cement.

[0028] The preparation of the above-mentioned environmentally friendly and energy-saving waterproof and heat-insulating material includes the following specific steps:

[0029] (1) Put the polypropylene short fiber and white cement into the mixer in proportion, and stir until the polypropylene short fiber is completely opened and in a dispersed state;

[0030] (2) Put redispersible latex powder, mica powder, heavy calcium powder, stones, quartz sand, hydroxypropyl methylcellulose,...

Embodiment 2

[0031] Embodiment 2 An environmentally friendly and energy-saving waterproof and heat-insulating material, which is made of the following raw materials in parts by weight:

[0032] 1.5 parts of redispersible latex powder, 5 parts of mica powder, 25 parts of heavy calcium powder, 20 parts of stone, 12.2 parts of quartz sand, 0.3 part of hydroxypropyl methylcellulose, 0.7 part of polycarboxylate superplasticizer, silyl 0.15 parts of powder, 0.15 parts of polypropylene short fiber, 35 parts of white cement.

[0033] The preparation method is basically the same as in Example 1.

Embodiment 3

[0034] Embodiment 3 An environmentally friendly and energy-saving waterproof and heat-insulating material, which is made of the following raw materials in parts by weight:

[0035] 1.8 parts of redispersible latex powder, 7 parts of mica powder, 22 parts of heavy calcium powder, 30 parts of stone, 10 parts of quartz sand, 0.2 part of hydroxypropyl methylcellulose, 0.15 part of polycarboxylate superplasticizer, silyl 0.12 parts of powder, 0.13 parts of polypropylene short fiber, and 28.6 parts of white cement.

[0036] The preparation method is basically the same as in Example 1.

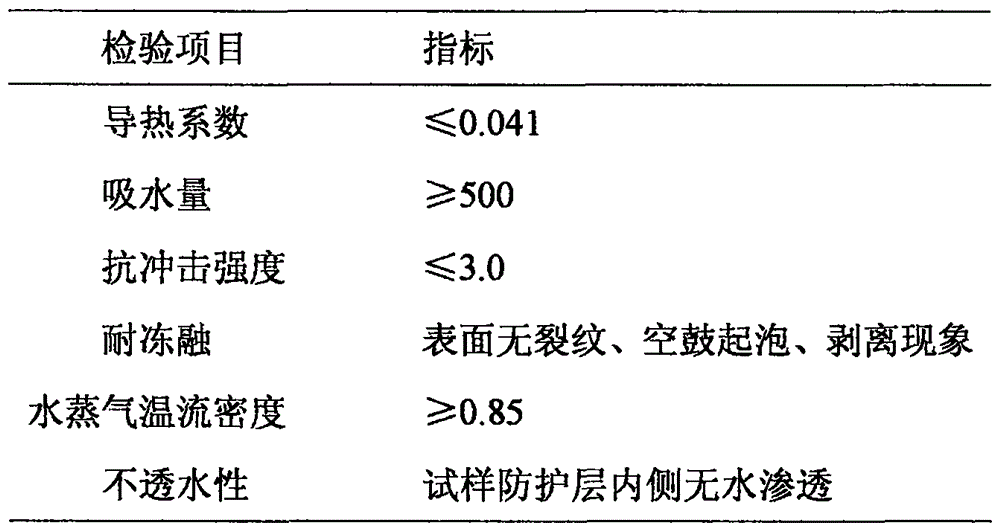

[0037] The main performance indicators of the material of the present invention are shown in Table 1.

[0038] Table 1 Main performance indicators of environmentally friendly and energy-saving waterproof and heat-insulating materials

[0039]

[0040] The above-mentioned environmentally friendly and energy-saving waterproof and heat-insulating materials can adopt the following construction techn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com