Dispersing agent and preparation method thereof, carbon nano tube dispersing slurry and preparation method thereof

A carbon nanotube and dispersant technology, applied in the field of electrochemical materials, can solve the problems of carbon nanotube thermoelectric properties and mechanical properties damage, carbon nanotube structure damage, performance decline, etc., to achieve wide application value, prevent aggregation, enhance compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

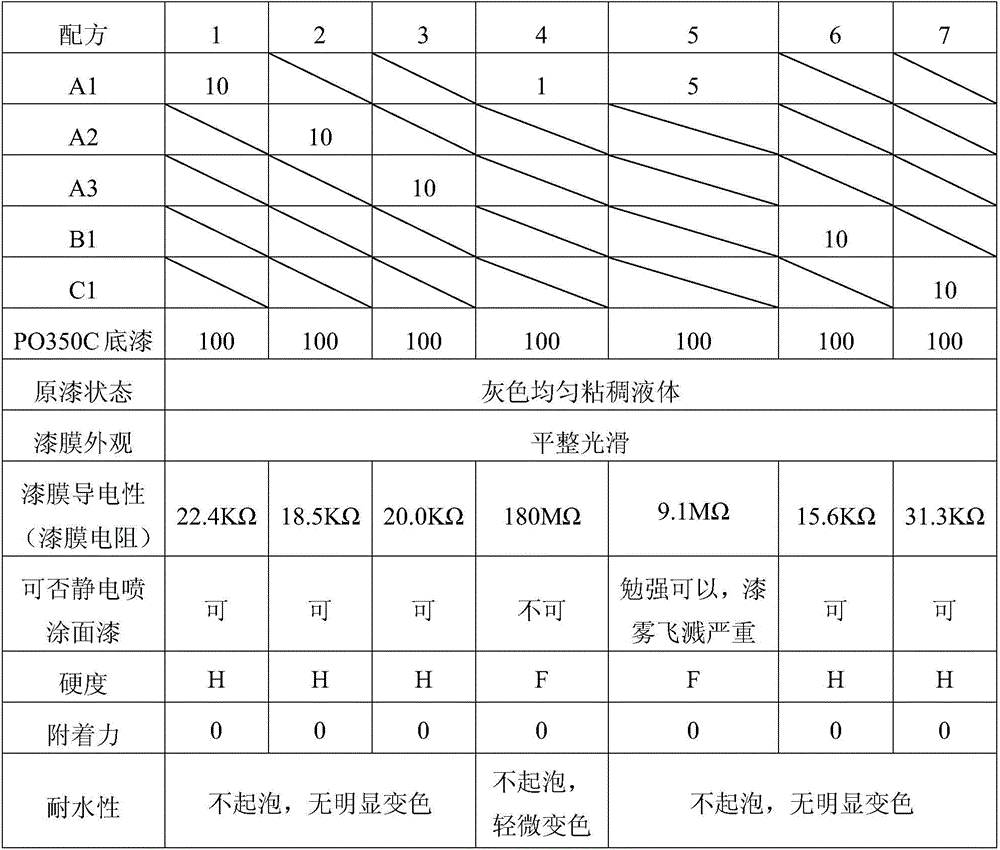

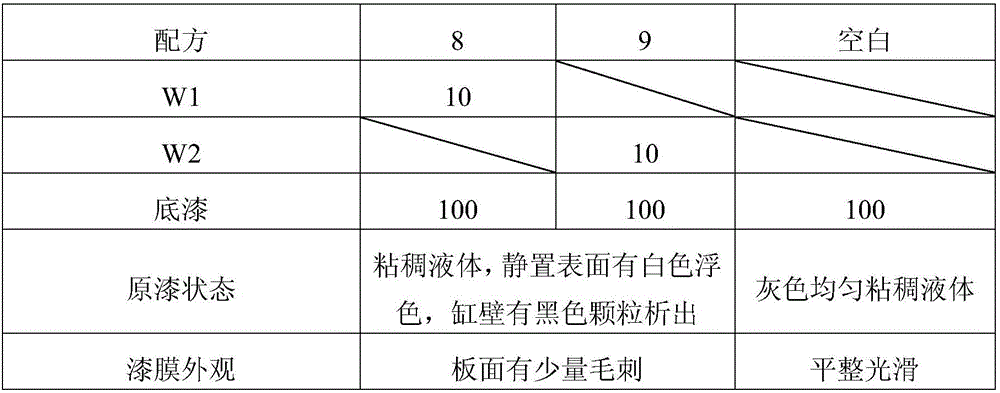

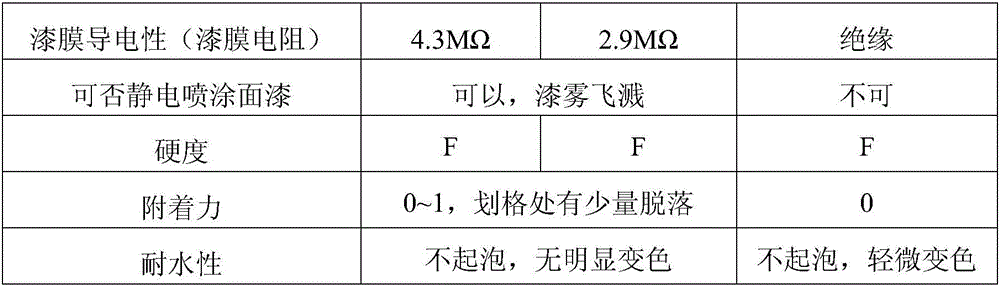

Examples

Embodiment 1

[0052] Preparation of carbon nanotube dispersant A

[0053] (1) Preparation of Main Chain Skeleton Copolymer a-1

[0054] Add 1000g of n-butyl acetate into a reaction kettle equipped with a heating mantle, thermocouple, stirrer, reflux condenser and dropping funnel, heat to reflux, and drop the monomer mixture and initiator solution at a constant speed at the same time, wherein the monomer mixture Containing 500g of n-butyl methacrylate, 500g of glycidyl methacrylate and 230g of hydroxyethyl methacrylate, the initiator solution was prepared by dissolving 60g of Vazo 67 in 180g of n-butyl acetate to initiate polymerization and control dripping The acceleration guarantees that the 2h dropwise addition is completed. When the monomer solution and the initiator solution are added dropwise, continue to add the initiator solution formed by 15g Vazo 67 and 45g butyl acetate for 30 minutes. After the initiator solution is added dropwise, keep the temperature at reflux for 30 minutes t...

Embodiment 2

[0060] Preparation of carbon nanotube dispersant B

[0061] (1) Preparation of main chain skeleton copolymer b-1

[0062] Add 1100g of n-butyl acetate in a reaction kettle equipped with a heating mantle, thermocouple, stirrer, reflux condenser and dropping funnel, heat to reflux, and drop monomer mixture and initiator solution at a constant speed at the same time, wherein the monomer mixture Containing 568g of n-butyl methacrylate, 284g of glycidyl methacrylate, 260g of hydroxyethyl methacrylate and 208g of styrene, the initiator solution was prepared by dissolving 23.4g of Vazo 67 in 190g of n-butyl acetate. Polymerization reaction, control the rate of addition to ensure that the addition is completed within 2 hours. When the monomer solution and the initiator solution have been added dropwise, continue to add the initiator solution formed by 5.8g Vazo 67 and 48g butyl acetate for 30 minutes. After the initiator solution has been added dropwise, keep the temperature at reflu...

Embodiment 3

[0068] Preparation of carbon nanotube dispersant C

[0069] (1) Preparation of Main Chain Skeleton Copolymer c-1

[0070] Add 1100g of n-butyl acetate in a reaction kettle equipped with a heating mantle, thermocouple, stirrer, reflux condenser and dropping funnel, heat to reflux, and drop monomer mixture and initiator solution at a constant speed at the same time, wherein the monomer mixture Containing 568g n-butyl methacrylate, 426g glycidyl methacrylate, 260g-4-hydroxybutyl methacrylate, the initiator solution is prepared by dissolving 75g AIBN in 190g n-butyl acetate to initiate polymerization, Control the drop rate to ensure that the 2h drop is completed. When the monomer solution and the initiator solution have been added dropwise, continue to add the initiator solution formed by 19g AIBN and 45g butyl acetate for 30 minutes. After the initiator solution has been added dropwise, keep the temperature at reflux for 30 minutes to ensure that the polymerization reaction is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com