Making method for improving flavor and quality of red wine with specific glycosidase

A technology for red wine and glycosidase, applied in the field of wine brewing, can solve problems such as few reports, and achieve the effects of simple operation, increased content and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of β-glucosidase derived from Aspergillus niger

[0028] specifically is:

[0029] (1) Preparation of fermented crude enzyme liquid

[0030] Aspergillus niger was passaged several times, streaked and inoculated on YPDA slant medium, and cultured statically in a 30°C incubator for 5 days. The mature Aspergillus niger spores were soaked and washed with sterile physiological saline to make a spore suspension and refrigerated at 4°C for later use. Draw the spore suspension and inoculate it into the liquid fermentation medium, the inoculum size is 5%, at 30°C, 180r·min -1 Under the fermentation system, the shake flask was cultured for 7 days. After the fermentation is finished, the fermented liquid is filtered through sterile gauze and centrifuged to obtain fermented crude enzyme liquid.

[0031] YPDA medium: Yeast powder 0.5g, protein powder 0.5g, glucose 1g, dissolve in deionized water and make up to 50mL, add 1g agar powder, sterilize at 115°C f...

Embodiment 2

[0043] Embodiment 2: red wine production

[0044] Taking the production of Cabernet Sauvignon red wine as an example, the production of wine is carried out according to the following methods. specifically is:

[0045] (1) Picking and sorting of red grapes: picking fresh red grapes manually or mechanically, sorting, and removing moldy and rotten fruits;

[0046] (2) Alcoholic fermentation: temperature-controlled fermentation, the main fermentation temperature is 28°C; after the main fermentation, the skin dregs are separated, and post-fermentation is carried out with full capacity, and the post-fermentation temperature is 20°C;

[0047] (3) Malic acid-lactic acid fermentation: post-fermentation finishes and carries out malic acid-lactic acid fermentation;

[0048] (4) Enzymolysis treatment: add β-D-glucosidase from different sources according to the addition amount of 3U / L, and enzymolysis treatment at 45°C for 4 hours;

[0049] (5) gumming clarification: wine liquor adopts ...

Embodiment 3

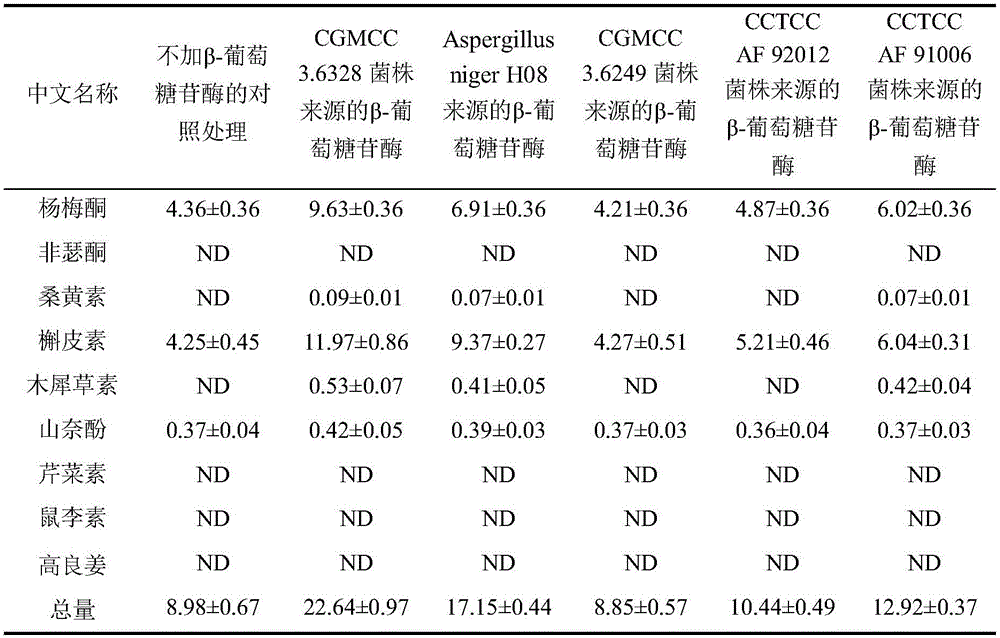

[0053] Embodiment 3: Different β-glucosidase treatment effect

[0054] Carry out the production of red wine according to the method for embodiment 2. The aroma components, the content of aroma substances, and the combined phenolic substances of wine samples before and after treatment with β-glucosidase from different sources were compared. Controls also included wine samples that were not treated with glycosidase.

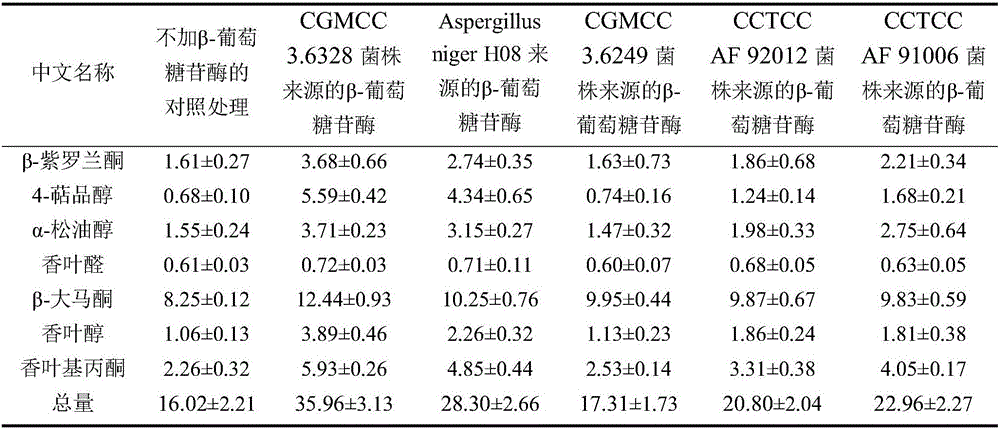

[0055] (1) The influence on the aroma of Cabernet Sauvignon dry red wine

[0056] The wines brewed by the process of the present invention and the reference wine sample are detected and analyzed by gas chromatography mass spectrometry (GC-MS), and the isoprene substances are analyzed for the important components of the fragrance of wine varieties-terpenes and C13 (Table 1). .

[0057] Table 1 Contents of terpenes and C13 norprenoids in Cabernet Sauvignon red wine treated with β-glucosidase from different sources (μg L -1 ±SD., n=3)

[0058]

[0059] The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com