Method for producing docosahexaenoic acid by fermentation tank substrate feeding

A docosahexaenoic acid and fermenter technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve problems such as unfavorable synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

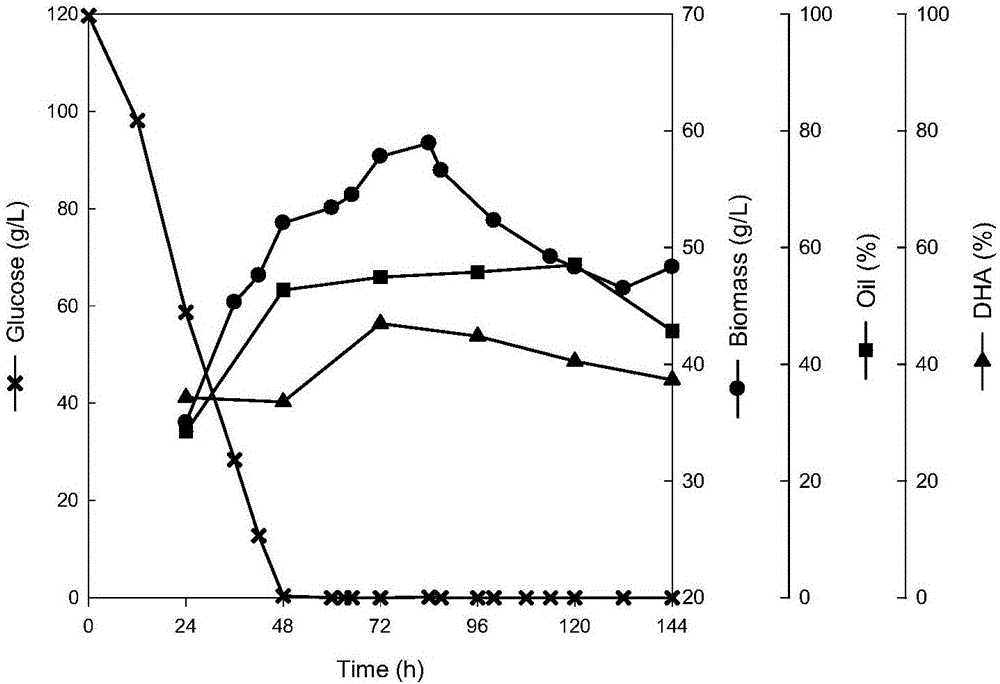

Embodiment 1

[0029] 1) Activation of strains: The strain Schizochytrium sp. LU310 preserved at -70°C was transferred to the plate medium, and cultured at 28°C for 24-48 hours to obtain activated strains and observe the colony morphology. The composition of the plate medium is (g / L): glucose 30, yeast powder 10, Na 2 SO 4 12. MgSO 4 2. KH 2 PO 4 1, (NH 4 ) 2 SO 4 1, K 2 SO 4 0.65, KCl 0.5, CaCl 2 .2H 2 O0.17, agar 15, pH adjusted to 6.5.

[0030] 2) Primary seed culture: select the plate colonies in step 1) with good morphology, pick them with an inoculating loop and insert them into a 250 mL flat-bottomed conical flask containing 50 mL of seed medium, and cultivate at 28° C. and 200 rpm for 24- 48h; the composition of seed medium is (g / L): glucose 30, yeast powder 10, Na 2 SO 4 12. MgSO 4 2. KH 2 PO 4 1, (NH 4 ) 2 SO 4 1, K 2 SO 4 0.65, KCl0.5, CaCl 2 .2H 2 O 0.17, the pH was adjusted to 6.5, and the first-class seed culture solution was obtained.

[0031]...

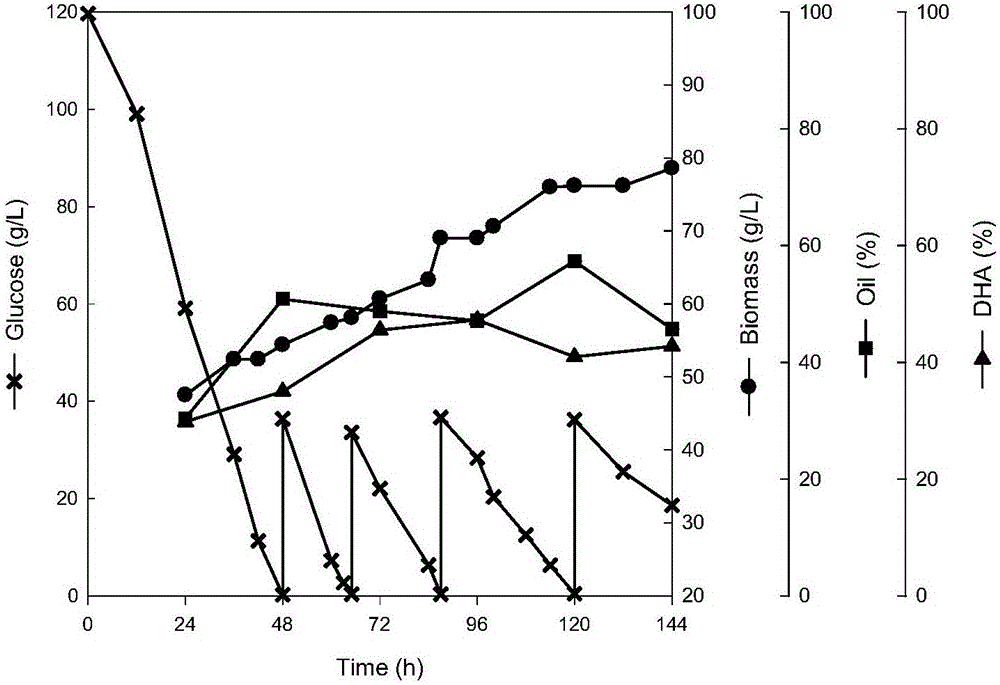

Embodiment 2

[0037]1) Activation of strains: The strain Schizochytrium sp. LU310 preserved at -70°C was transferred to the plate medium, and cultured at 28°C for 24-48 hours to obtain activated strains and observe the colony morphology. The composition of the plate medium is (g / L): glucose 30, yeast powder 10, Na 2 SO 4 12. MgSO 4 2. KH 2 PO 4 1, (NH 4 ) 2 SO 4 1, K 2 SO 4 0.65, KCl 0.5, CaCl 2 .2H 2 O0.17, agar 15, pH adjusted to 6.5.

[0038] 2) Primary seed culture: select the plate colonies in step 1) with good morphology, pick them with an inoculating loop and insert them into a 250 mL flat-bottomed conical flask containing 50 mL of seed medium, and cultivate at 28° C. and 200 rpm for 24- 48h; the composition of seed medium is (g / L): glucose 30, yeast powder 10, Na 2 SO 4 12. MgSO 4 2. KH 2 PO 4 1, (NH 4 ) 2 SO 4 1, K 2 SO 4 0.65, KCl0.5, CaCl 2 .2H 2 O 0.17, the pH was adjusted to 6.5, and the first-class seed culture solution was obtained.

[0039] ...

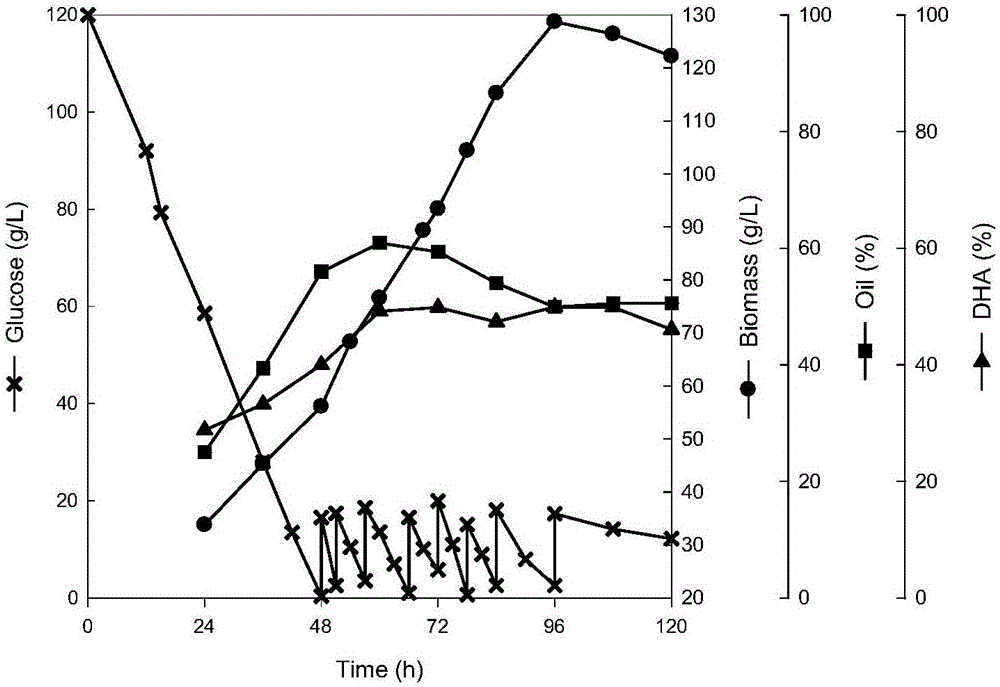

Embodiment 3

[0045] 1) Activation of strains: The strain Schizochytrium sp. LU310 preserved at -70°C was transferred to the plate medium, and cultured at 28°C for 24-48 hours to obtain activated strains and observe the colony morphology. The composition of the plate medium is (g / L): glucose 30, yeast powder 10, Na 2 SO 4 12. MgSO 4 2. KH 2 PO 4 1, (NH 4 ) 2 SO 4 1, K 2 SO 4 0.65, KCl 0.5, CaCl 2 .2H 2 O0.17, agar 15, pH adjusted to 6.5.

[0046] 2) Primary seed culture: select the plate colonies in step 1) with good morphology, pick them with an inoculating loop and insert them into a 250 mL flat-bottomed conical flask containing 50 mL of seed medium, and cultivate at 28° C. and 200 rpm for 24- 48h; the composition of seed medium is (g / L): glucose 30, yeast powder 10, Na 2 SO 4 12. MgSO 4 2. KH 2 PO 4 1, (NH 4 ) 2 SO 4 1, K 2 SO 4 0.65, KCl0.5, CaCl 2 .2H 2 O 0.17, the pH was adjusted to 6.5, and the first-class seed culture solution was obtained.

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com