Corynebacterium glutamicum and application

A technology of Corynebacterium glutamicum and glutamic acid rods, applied in the field of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Chemical mutagenesis of Corynebacterium glutamicum

[0050] (1) Using the Corynebacterium glutamicum isolated in the soil as the starting strain, first activate it on the slope of the complete medium, and cultivate it at 32°C for 12 hours;

[0051] (2) Inoculate in a liquid seed medium from a slope, the seed medium is LB, and cultivate at 32° C. for 12 hours;

[0052] (3) Wash the cultured cells with physiological saline, and after repeating once, resuspend the bacteria with a phosphate buffer solution with a pH of 7.0 to make 10 7 -10 8 Cells / mL of bacterial suspension;

[0053] (4) Take 5-10 mL of bacterial suspension, add it to a sterile test tube, then add 1% (V / V) diethyl sulfate, seal the test tube with a cotton plug, and shake for 30-40 minutes;

[0054] (5) Dilute with an appropriate amount of sterile water, spread on the resistance screening medium containing sulfaguanidine and L-valine structural analogues, cultivate at 32°C, and wait for a single colony to...

Embodiment 2

[0058] Genome sequencing of Corynebacterium glutamicum XV

[0059] (1) Extraction of genome: use the bacterial genome DNA extraction kit of PROMEGA company Genomic DNA Purification Kit A1120, using a nucleic acid analyzer to ensure that the quality of genomic DNA meets the requirements of sequencing;

[0060] (2) The genome was sequenced using the third-generation sequencing platform PacBio RS II;

[0061] (3) Genome assembly was performed using the assembly software provided by PacBio, and routine comparative genome analysis was performed using related software. On the basis of the genome sequence, by comparing the genome sequences of the valine-producing strain Corynebacterium glutamicum XV and the standard strain of Corynebacterium glutamicum ATCC 13032, it was found that there are more bases in the gene sequence related to valine synthesis Base mutations, base mutations lead to the following changes in the amino acid sequences of each gene-encoded product (using "amino ...

Embodiment 3

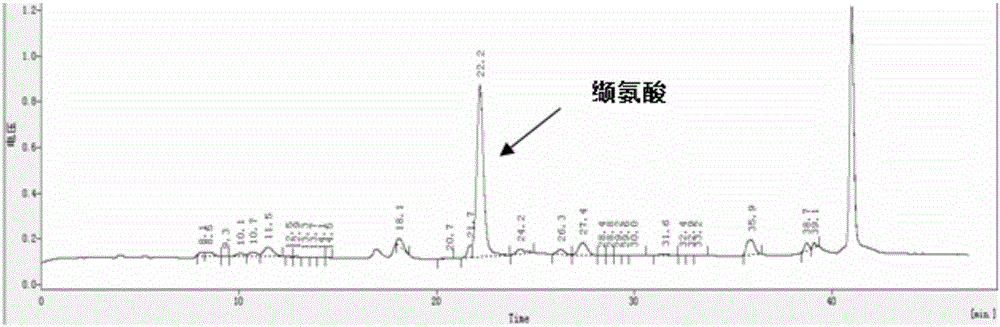

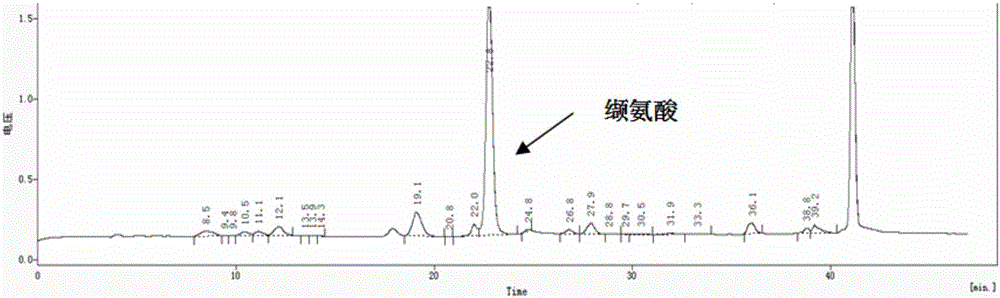

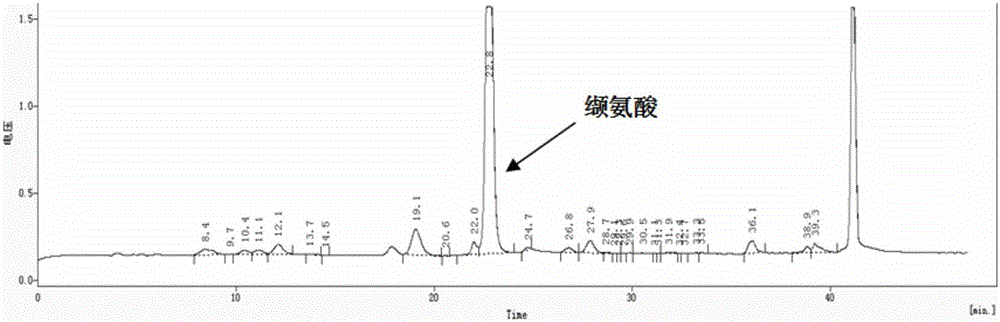

[0073] Comparison of valine synthesis ability of strains before and after gene mutation

[0074] (1) Activated slant medium (g / L): glucose 10, beef extract 10, peptone 10, yeast powder 5, NaCl 5, agar strip 20, pH 6.7-7.2, and the rest is distilled water;

[0075] (2) Shake flask seed medium (g / L): glucose 30, yeast powder 5, bean cake powder hydrolyzate 20, corn steep liquor 20, NaCl5, MgSO 4 ·7H 2 O2, KH 2 PO 4 12H 2 O2, FeSO 4 ·7H 2 O 0.01, MnSO 4 ·H 2 O 0.01, leucine 0.1, isoleucine 0.1, phenol red solution (0.4g / L) 20mL, pH 6.7-7.2, the rest is distilled water;

[0076] (3) Shake flask fermentation medium (g / L): glucose 60, bean cake powder hydrolyzate 25, corn steep liquor 40, MgSO 4 ·7H 2 O2, KH 2 PO 4 12H 2 O2, FeSO 4 ·7H 2 O 0.01, MnSO 4 ·H 2 O 0.01, V B1 0.01, phenol red solution (0.4g / L) 20mL, pH 6.7-7.2, the rest is distilled water;

[0077] (4) Incline culture: place in a 32°C incubator, cultivate the first-generation activated slope for 24 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com