Double-layer emulsified liquid drop, medicine carrying micro-sphere, method for preparing same and device for preparing double-layer emulsified liquid drop

A technology for preparing a device and an emulsion, which is applied in the fields of biomedical materials and microfluidics, can solve the problems of cumbersome operation, high cost, complicated device structure, etc., and achieve the effects of increasing safety, preventing sudden release, and controlling drug release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1, the preparation of polyvinyl alcohol and sodium alginate mixed aqueous solution

[0078] Weigh 10 grams of polyvinyl alcohol solid particles and add 90 grams of distilled water, stir and dissolve evenly under the condition of 75-80 ° C to form a transparent liquid, and obtain a 10% by mass polyvinyl alcohol aqueous solution.

[0079] Weigh 5 grams of sodium alginate solid particles and add 95 grams of distilled water, stir evenly at room temperature and dissolve into a transparent liquid to obtain a 5% by mass sodium alginate aqueous solution.

[0080] According to the mass fraction, the above aqueous solution of polyvinyl alcohol and sodium alginate was prepared into a mixed aqueous solution of polyvinyl alcohol and sodium alginate with final concentrations of 1% and 0.5%, respectively.

[0081] The continuous phase fluid used in the embodiment is paraffin oil containing 2% EM90. Weigh 98 grams of paraffin oil and add 2 grams of EM90 to obtain a 2% mass p...

Embodiment 2

[0087]A preparation device for double-layer emulsified droplets, which is composed of a first-stage microchannel and a second-stage microchannel in series;

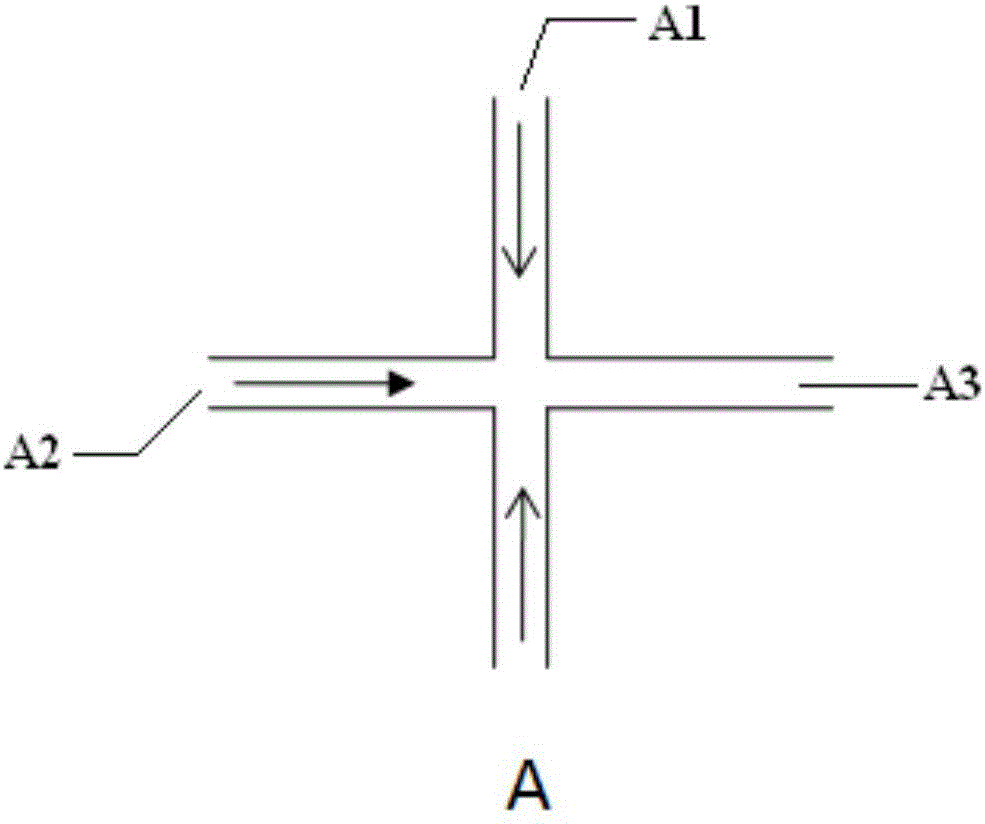

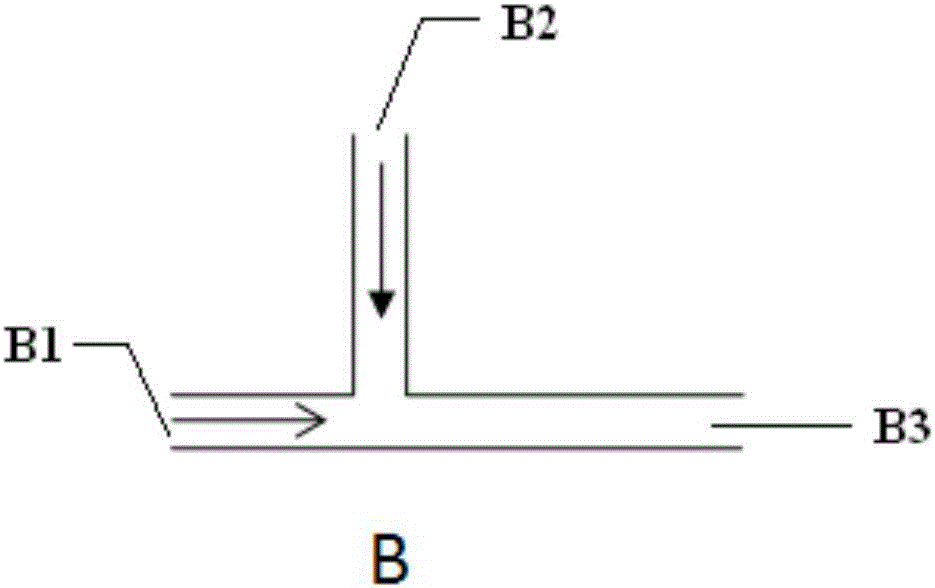

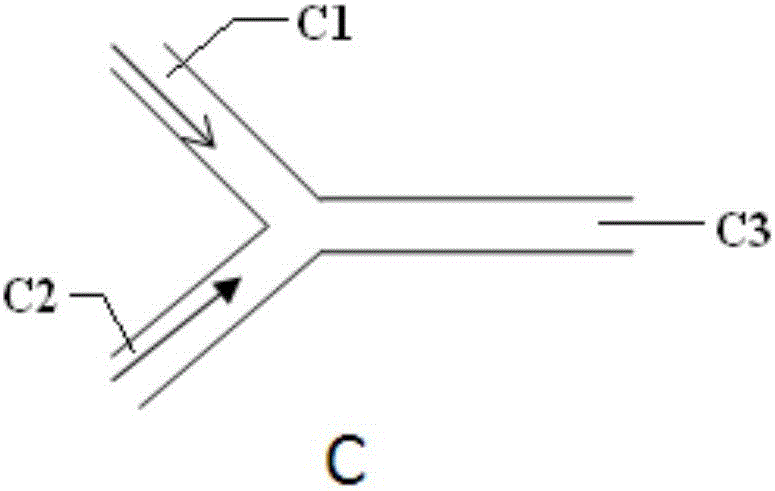

[0088] The first-stage microchannel is a cross-shaped microchannel A, a T-shaped microchannel B, a Y-shaped microchannel C or a co-flow microchannel D;

[0089] Described second-level microchannel includes two types of microchannels of Class A or Class B;

[0090] The Class A second-stage microchannel includes a coaxially connected discrete phase fluid channel, a continuous phase fluid channel 5 and a collection channel 6, the discrete phase fluid channel and the collection channel 6 are nested in the continuous phase fluid channel 5, and the discrete phase One end of the fluid channel close to the collection channel 6 is tapered, and the discrete phase fluid channel is equally divided into a single-layer emulsified micro-droplet inlet channel 3 and a catalyst or curing agent channel 4 along the central axis;

[0091] De...

Embodiment 3

[0097] Embodiment 3, preparation of drug-loaded microspheres:

[0098] Selection of the first stage microchannel Figure 1A In the cross-shaped first-stage microchannel shown, the diameter of the internal phase fluid channel A2 is 150 microns, and the diameter of the interphase fluid channel A1 is 200 microns; the second-stage microchannel is selected Figure 2A In the class A second-stage microchannel shown, the diameter of the discrete phase fluid channel 5 is 250 microns, and the diameter of the continuous phase fluid channel 5 is 300 microns.

[0099] The mass percentage concentration of the mixed aqueous solution of polyvinyl alcohol and sodium alginate is 1.5% and 0.5% respectively, and the aqueous solution of the crosslinking agent is 50% by mass of glutaraldehyde aqueous solution. The polyvinyl alcohol aqueous solution and the glutaraldehyde aqueous solution are premixed according to the mass ratio of solute polyvinyl alcohol:crosslinking agent=3:2, and the aqueous ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com