Method for preparing carbon/calcium phosphate/ferroferric oxide composite structured nano particles

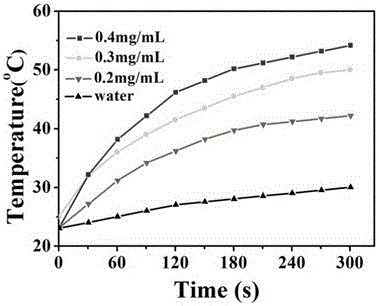

A technology of ferric tetroxide and composite structure, which is applied to preparations for in vivo experiments, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., to achieve good dispersibility, good light-heat conversion ability, The effect of the simple method of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

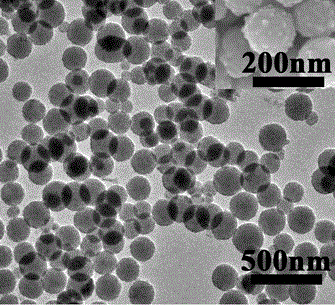

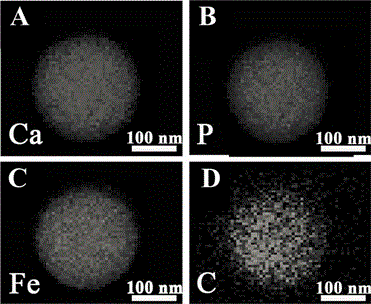

Embodiment 1

[0022] In a 100 mL round bottom flask, 5 mg calcium hydroxide, 30 mg polyacrylic acid and 15 mL deionized water were added sequentially, at 25 o C under magnetic stirring for 6 min until the solution was clear and transparent. Then, 30 mL of isopropanol was slowly added dropwise to the reaction solution under magnetic stirring. After the dropwise addition, 5 mg of ferrous chloride was added to the solution. After stirring at room temperature for 1 h, 6 mg of diammonium hydrogen phosphate was added to the solution. , stirred at room temperature for 8 h. Then the reaction solution was centrifuged (7000 rpm, 10 min), and the obtained precipitate was o After drying in a C oven for 10 h, they were then calcined at 500 °C for 10 h under the protection of argon to obtain carbon / calcium phosphate / ferric oxide composite nanoparticles.

Embodiment 2

[0024] In a 100 mL round bottom flask, 10 mg calcium hydroxide, 50 mg polyacrylic acid and 30 mL deionized water were added sequentially, at 25 o C under magnetic stirring for 10 min until the solution was clear and transparent. Then, 60 mL of isopropanol was slowly added dropwise to the reaction solution under magnetic stirring. After the dropwise addition, 10 mg of ferrous chloride was added to the solution. After stirring at room temperature for 1 h, 12 mg of diammonium hydrogen phosphate was added to the solution. , stirred at room temperature for 10 h. Then the reaction solution was centrifuged (8000 rpm, 10 min), and the obtained precipitate was o After drying in a C oven for 15 h, they were then calcined at 700 °C for 8 h under the protection of argon to obtain carbon / calcium phosphate / ferric oxide composite nanoparticles.

Embodiment 3

[0026] Add 8 mg of calcium hydroxide, 40 mg of polyacrylic acid and 20 mL of deionized water to a 100 mL round-bottomed flask successively, at 25 o C under magnetic stirring for 10 min until the solution was clear and transparent. Then, 50 mL of isopropanol was slowly added dropwise to the reaction solution under magnetic stirring. After the dropwise addition, 8 mg of ferrous chloride was added to the solution. After stirring at room temperature for 1 h, 10 mg of diammonium hydrogen phosphate was added to the solution. , stirred at room temperature for 12 h. Then the reaction solution was centrifuged (9000 rpm, 5 min), and the obtained precipitate was o After drying in a C oven for 12 h, they were then calcined at 600 °C for 6 h under the protection of argon to obtain carbon / calcium phosphate / ferric oxide composite nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com