Nitrogen and phosphorus removal system for treating circulating cooling discharge water of power plant

A technology of denitrification and phosphorus removal and circulating cooling, applied in the field of denitrification and phosphorus removal systems, can solve the problem of total nitrogen, total phosphorus and organic matter in sewage that cannot meet the discharge standards, lack of proper denitrification and phosphorus treatment technology, dissolved oxygen saturation, suspended solids and high salinity, to achieve the effect of good effluent quality, small footprint and high organic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

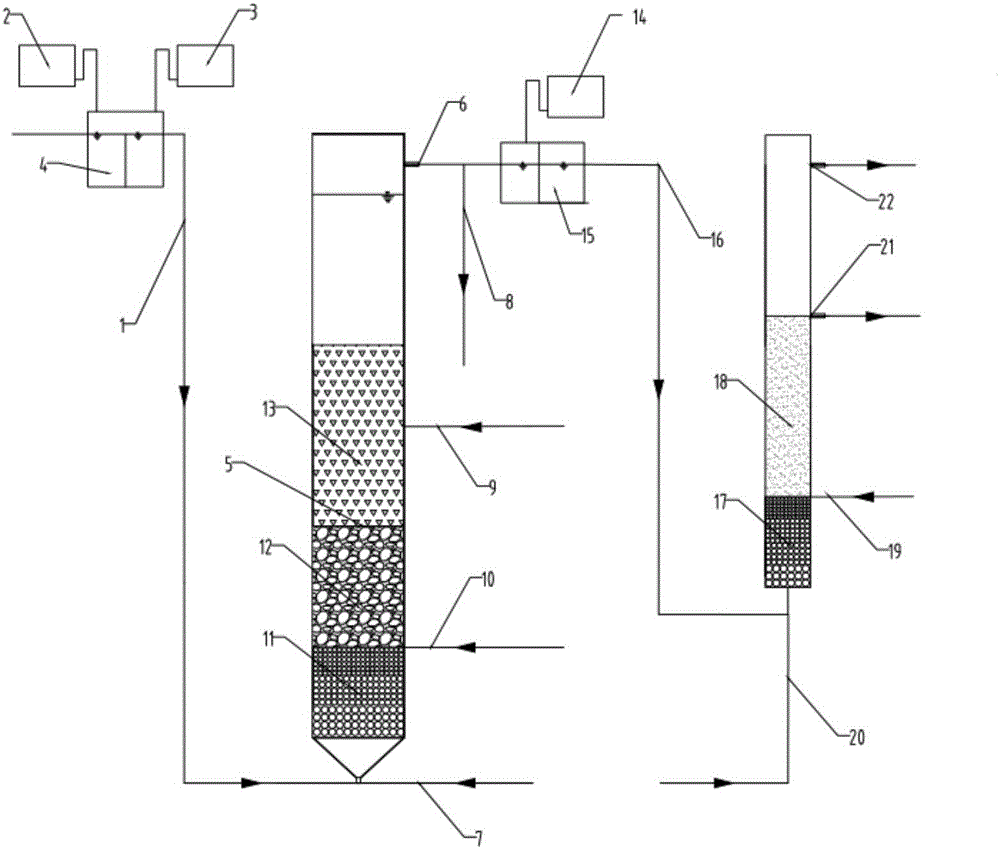

[0029] use figure 1 In the pilot plant shown, the composite biological filter has a diameter of 0.6m, a height of 4m, and an effective volume of 565L. The filter material is a combination of volcanic rock and zeolite. A gas-fired thermal power plant circulating cooling sewage, dissolved oxygen 8.5-9.0mg / L, total nitrogen concentration 35-60mg / L, sodium acetate as an additional carbon source, carbon-nitrogen ratio 3.5:1, total phosphorus 0.4-2.0mg / L, Suspension 9-18mg / L.

[0030] The total nitrogen load in the volume is 0.45-0.76kg / m 3 Under the condition of d (influent flow rate 300L / h), after 30 days of operation, the total nitrogen effluent concentration is lower than 10mg / L, the total nitrogen removal rate is between 71.4% and 83.3%; the suspended matter is reduced to 5mg / L The excess carbon source can be removed by aeration in the upper stage of the composite biological filter, and the chemical oxygen demand of the effluent is lower than 20mg / L; the effluent of the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com