Polybenzoxazole nanofiber high-intensity heat insulation fireproof aerogel and preparation method thereof

A polybenzoxazole and nanofiber technology, which is applied in aerogel and its preparation, polybenzoxazole nanofiber high-strength thermal insulation and fireproof aerogel and its preparation field, can solve the limitation of aerogel physicochemical Stability and mechanical properties, low mechanical strength of aerogels, low inherent mechanical strength, etc., to achieve the effects of high mechanical properties, high porosity, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

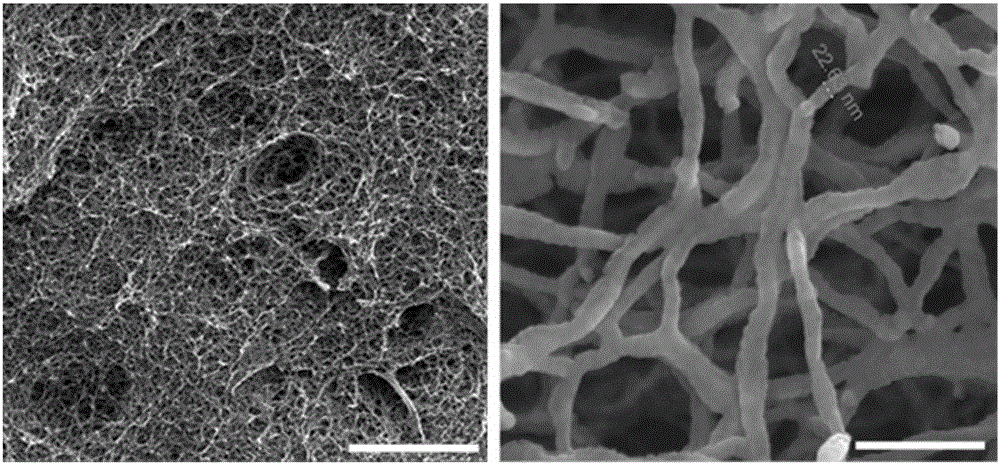

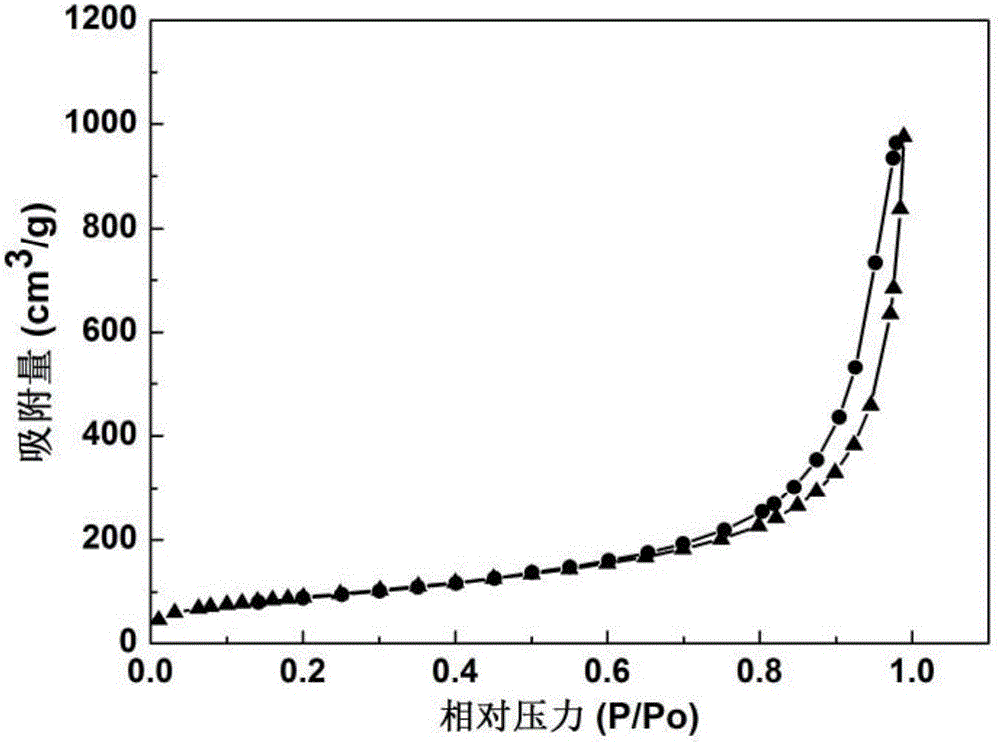

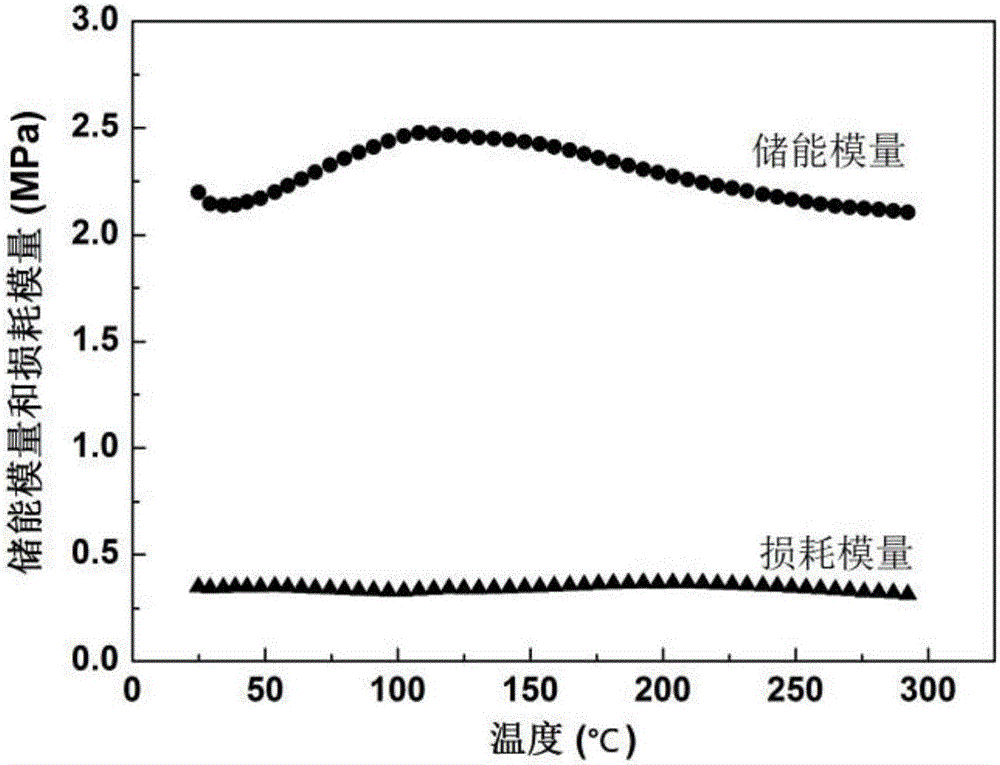

[0018] A polybenzoxazole nanofiber high-strength heat-insulating and fireproof aerogel involved in this embodiment has a network interpenetrating structure composed of nanofibers inside the product, and the diameter of the nanofibers is 10-50 nm and the density is 20 ~50mg cm -3 , The specific surface area is 200 ~ 400m 2 g -1 , the porosity is 95-99%, and the storage modulus is 2-2.5MPa.

Embodiment 2

[0020] Dissolve commercial 1wt% PBO fibers in a mixed acid solution with a volume ratio of methanesulfonic acid and trifluoroacetic acid of 0.8:9.2 (1wt% = 1g PBO fiber to 100mL mixed acid solution), stir for 8 minutes to make a PBO mixed acid solution and pour it into in the mold. Then, put the PBO mixed acid solution together with the mold in an environment with a humidity of 98% for 47 hours to make the PBO mixed acid solution gel. The PBO gel was soaked and washed with water until the pH value of the PBO gel was equal to 7, and then dried with supercritical carbon dioxide (1300 psi, 40° C.) for 11 hours to obtain the PBO nanofiber airgel.

[0021] The obtained PBO nanofiber airgel is not deformed and shrinks, the internal fiber network structure is uniform, the fiber diameter is 10-20nm, and the density is 45-50mg cm -3 , the specific surface area is 200~270m 2 g -1 , The porosity is 95-96%.

Embodiment 3

[0023] Dissolve commercial 1wt% PBO fibers in a mixed acid solution of methanesulfonic acid and trifluoroacetic acid with a volume ratio of 0.8:9.3, stir for 10 minutes, and pour the PBO mixed acid solution into a mold. Then, put the PBO mixed acid solution together with the mold in an environment with a humidity of 97% for 48 hours to make the PBO mixed acid solution gel. The PBO gel was soaked and washed with water until the pH value of the PBO gel was equal to 7, and then dried with supercritical carbon dioxide (1300 psi, 40° C.) for 12 hours to obtain the PBO nanofiber airgel.

[0024] The obtained PBO nanofiber airgel is not deformed and shrinks, the internal fiber network structure is uniform, the fiber diameter is 20-30nm, and the density is 40-45mg cm -3 , the specific surface area is 270~325m 2 g -1 , The porosity is 96-98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com