Fireproof coating for self-repairing type steel structure and preparation method thereof

A fire-retardant coating and self-repairing technology, applied in fire-resistant coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor durability, cracking, and poor fire performance, and achieve increased durability, reduced dosage, Guaranteed self-healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

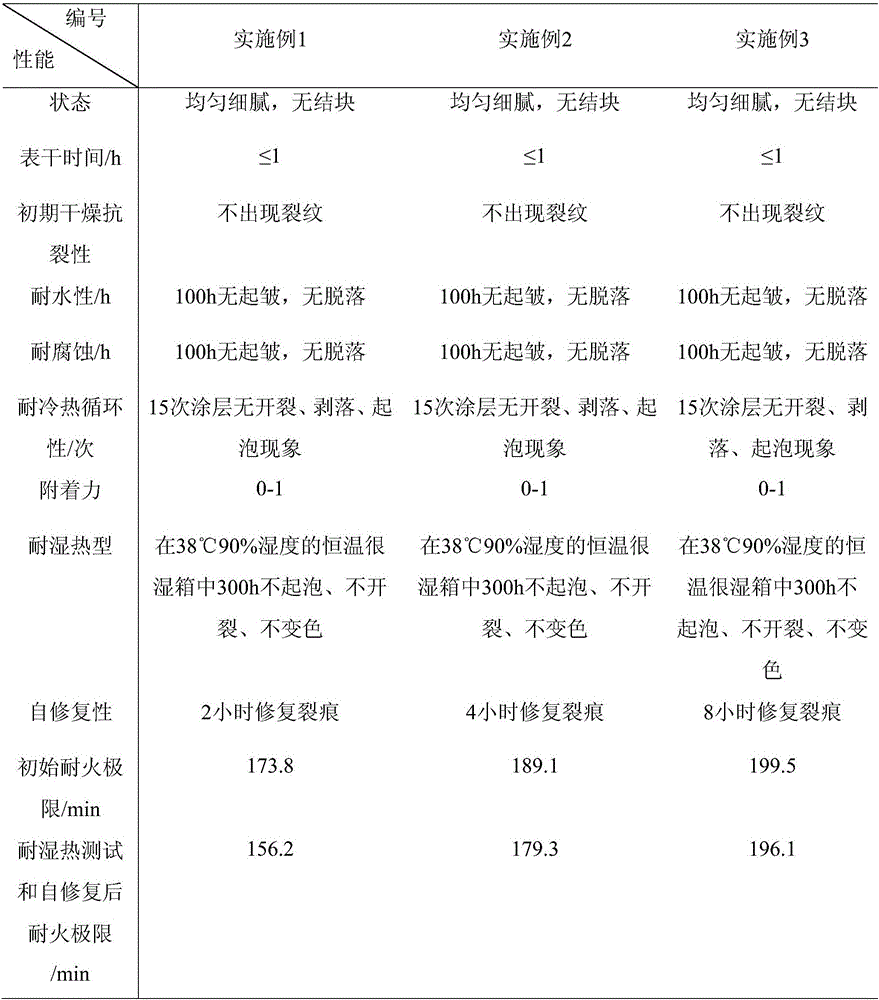

Examples

preparation example Construction

[0034] The preparation method of described epoxy resin microcapsules is: add 10g urea and 27g 37% formaldehyde aqueous solution in the flask, make urea dissolve completely by magnetic stirring action; After the obtained solution is mixed evenly, adjust the pH value of the solution with triethylamine 8-9, keep a constant temperature of 70°C, react for 1-1.5h, and obtain a viscous milky white wall material; dilute 33g of epoxy resin E44 with 3g of diluent 692 in advance, and add sodium dodecylsulfonate aqueous solution (0.4 g sodium dodecylsulfonate and 10mL deionized water), stirred at 1000r / min for 20 minutes to obtain the core material; under stirring, the gained milky white wall material was added to the core material, and then 1g of resorcinol was added Phenol was stirred, and 0.1g of defoamer n-octanol was added dropwise, and the pH value of the system was adjusted to 3-4 after stirring evenly, and reacted at 60°C for 3 hours; the obtained product was washed with distilled ...

Embodiment 1

[0037] A self-repairing steel structure fireproof coating, the components and their mass percentages are: epoxy modified water-based polyurethane emulsion 20%, melamine formaldehyde resin microencapsulated ammonium polyphosphate 35%, polyurethane microencapsulated inorganic particles 15%, self-healing microcapsules 15%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, antifungal agent 1%, n-octanol 0.5%, and the rest is water (deionized water); The preparation method of the self-repairing steel structure fireproof coating comprises the following steps:

[0038] 1) weighing each component according to the mass percentage of each component, grinding melamine microencapsulated ammonium polyphosphate and polyurethane microencapsulated inorganic particles into powder, adding deionized water, and fully grinding;

[0039] 2) Add hydroxyethyl cellulose, defoamer, dispersant and antifungal agent, and fully grind;

[0040] 3) adding epoxy-modified water-based polyurethane e...

Embodiment 2

[0042] A self-repairing steel structure fireproof coating, the components and their mass percentages are: epoxy modified water-based polyurethane emulsion 25%, melamine formaldehyde resin microencapsulated ammonium polyphosphate 30%, polyurethane microencapsulated inorganic particles 20%, self-healing microcapsules 10%, hydroxyethyl cellulose 1%, dispersant 0.5%, defoamer 0.5%, antifungal agent 1%, n-octanol 1%, and the rest is water (deionized water). Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com