High-heat-conductive and high-adhesion-strength organic silicon pouring sealant, preparation method thereof, and method therewith for sealing end portion of motor

A technology of silicone potting glue and high thermal conductivity, which is applied in the manufacture of motor generators, electromechanical devices, polymer adhesive additives, etc. It can solve the problems of unreachable use requirements, poor thermal conductivity, and poor mechanical properties. To achieve the effect of ensuring dispersion and wetting, good mechanical properties, and good self-defoaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

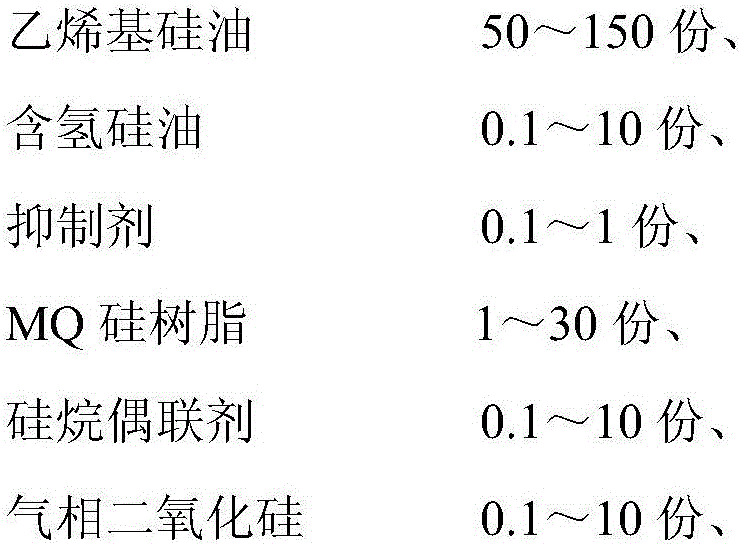

[0038] A silicone potting compound with high thermal conductivity and high bonding strength according to the present invention, comprising component A and component B with a mass ratio of 1:1, wherein component A is mainly prepared by mixing the following raw materials:

[0039] Vinyl silicone oil (the mass content of vinyl is 0.32%, viscosity is 1000mPa.S) 90g,

[0040] Hydrogen-containing silicone oil (the mass content of hydrogen is 0.5%) 10g,

[0041] Inhibitor (1-ethynylcyclohexanol) 0.1g,

[0042] MQ silicone resin (containing vinyl MQ silicone resin, M / Q is 0.5~1.5) 10g,

[0043] Silicone coupling agent (glycidyl ether oxypropyl trimethoxysilane) 1g,

[0044] Surfactant (FS-60) 1g,

[0045] Fumed silica 0.5g;

[0046] Thermally conductive filler (a mixture of spherical alumina with a particle size of 10-30um and spherical aluminum nitride with a particle size of 0.1-10um, wherein both spherical alumina and spherical aluminum nitride have been treated with a silane cou...

Embodiment 2

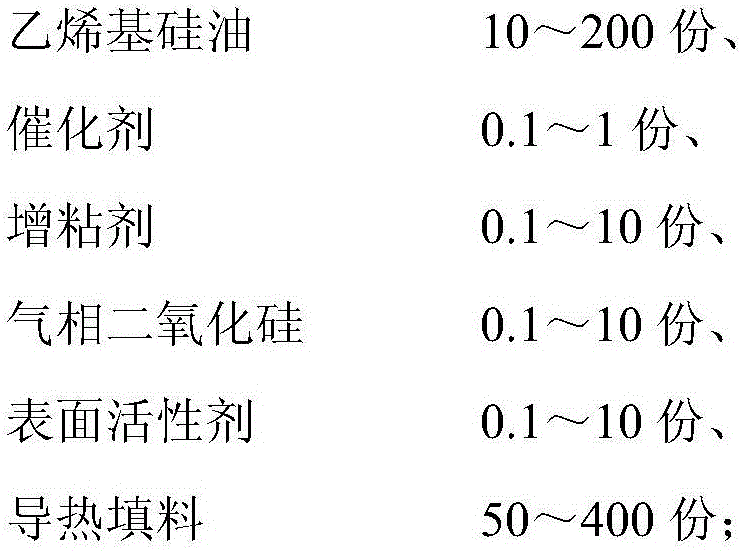

[0064] A silicone potting compound with high thermal conductivity and high bonding strength according to the present invention, comprising component A and component B with a mass ratio of 0.97:1, wherein component A is mainly prepared by mixing the following raw materials:

[0065] Vinyl silicone oil (the mass content of vinyl is 0.25%, viscosity is 3000Pa·S) 80g,

[0066] Hydrogen-containing silicone oil (the mass content of hydrogen is 0.18%) 15g,

[0067] Inhibitor (1-ethynyl cyclohexanol) 0.15g,

[0068] MQ silicone resin (containing vinyl MQ silicone resin, M / Q is 0.85) 10g,

[0069] Siloxane coupling agent (aminopropyltriethoxysilane) 1g,

[0070] Thermally conductive filler (a mixture of spherical alumina with a particle size of 10-30um and spherical aluminum nitride with a particle size of 0.1-10um, wherein both spherical alumina and spherical aluminum nitride have been treated with a silane coupling agent) 400g,

[0071] Surfactant (FS-60) 1g,

[0072] Fumed silic...

Embodiment 3

[0090] A silicone potting compound with high thermal conductivity and high bonding strength according to the present invention, comprising component A and component B with a mass ratio of 0.98:1, wherein component A is mainly prepared by mixing the following raw materials:

[0091] Vinyl silicone oil (the mass content of vinyl is 0.32%, viscosity is 1000mPa·S) 100g,

[0092] Hydrogen-containing silicone oil (the mass content of hydrogen is 0.18%) 25g,

[0093] Inhibitor (1-ethynyl cyclohexanol) 0.15g,

[0094] MQ silicone resin (containing vinyl MQ silicone resin, M / Q is 0.5) 15g,

[0095] Silicone coupling agent (glycidyl ether oxypropyl trimethoxysilane) 1g,

[0096] Thermally conductive filler (a mixture of spherical alumina with a particle size of 10-30um and spherical aluminum nitride with a particle size of 0.1-10um, wherein both spherical alumina and spherical aluminum nitride have been treated with a silane coupling agent) 400g;

[0097] Surfactant (FS-60) 1g

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com