Preparation method of rapid and high water-absorption non-woven cloth

A non-woven fabric, high water absorption technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems that take hours or even days to achieve, poor reusability, unsuitable for emergency rescue, etc., to achieve Overcome the effects of slow water absorption, stable shape and structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of fast superabsorbent nonwoven fabric, concrete implementation steps are as follows:

[0034] 1) Treat 1 g of polyester nonwoven fabric with ethanol ultrasonic vibration to remove organic impurities on the surface, then dry it, and put the dried polyester nonwoven fabric into a polypropylene sample bag;

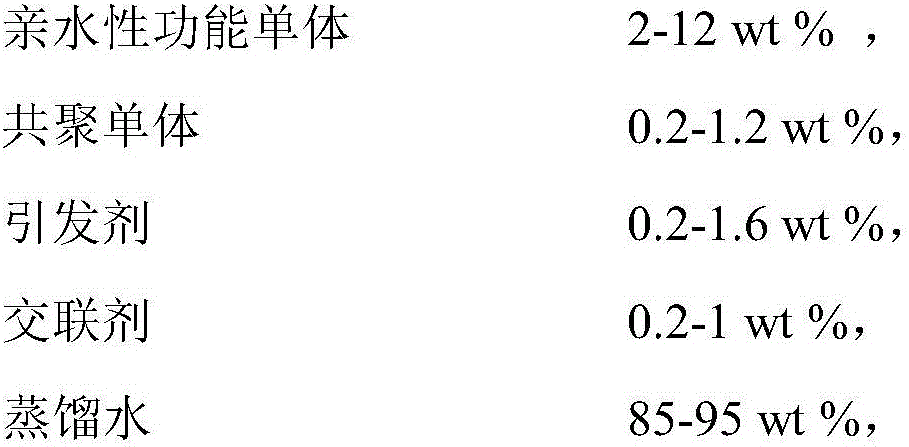

[0035] 2) Based on the total weight of the mixed grafting solution, 4wt% of acrylic acid, 0.4wt% of acrylamide, 0.4wt% of potassium persulfate and 0.2wt% of N, N-methylenebisacrylamide were dissolved in The distilled water of 95wt% is mixed with 50ml mixed grafting liquid, pours in the above-mentioned polypropylene sample bag that polyester nonwoven fabric is housed, fills with nitrogen for 30min, and polyester nonwoven fabric is soaked;

[0036] 3) Pour out the excess grafting solution after soaking the polyester nonwoven fabric, place the polypropylene sample bag containing the polyester nonwoven fabric in an ultraviolet irradiation devi...

Embodiment 2

[0038] A kind of preparation method of fast superabsorbent nonwoven fabric, implementation steps are as follows:

[0039] 1) Treat 2 g of polyester nonwoven fabric with ethanol ultrasonic vibration to remove organic impurities on the surface, then dry it, and put the dried polyester nonwoven fabric into a polypropylene sample bag;

[0040] 2) Based on the total weight of the mixed grafting liquid, 4wt% of acrylic acid, 0.6wt% of methacrylamide, 0.6wt% of ammonium persulfate and 0.4wt% of diallyl itaconate were dissolved in 94.4 The distilled water of wt% is mixed with 50ml mixed grafting liquid, pours in the above-mentioned polypropylene sample bag that polyester nonwoven fabric is housed, fills with nitrogen gas 30min, and polyester nonwoven fabric is soaked;

[0041]3) Pour out the excess grafting solution after soaking the polyester nonwoven fabric, place the polypropylene sample bag containing the polyester nonwoven fabric in an ultraviolet irradiation device, and irradiat...

Embodiment 3

[0043] A kind of preparation method of fast superabsorbent nonwoven fabric, implementation steps are as follows:

[0044] 1) Treat 2 g of polyester nonwoven fabric with ethanol ultrasonic vibration to remove organic impurities on the surface, then dry it, and put the dried polyester nonwoven fabric into a polypropylene sample bag;

[0045] 2) Based on the total weight of the mixed grafting solution, 8 wt% of methyl acrylate, 0.6 wt% of acrylamide, 0.6 wt% of ammonium persulfate and 0.6 wt% of N,N-methylenebisacrylamide Dissolved in 90.2wt% distilled water to prepare 100ml mixed grafting solution, pour it into the above-mentioned polypropylene sample bag equipped with polyester non-woven fabric, fill with nitrogen for 40min, and soak the polyester non-woven fabric;

[0046] 3) Pour out the excess grafting solution after soaking the polyester nonwoven fabric, place the polypropylene sample bag containing the polyester nonwoven fabric in an ultraviolet irradiation device, and irr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com