Heat-resisting protective agent for freeze-dried vaccine and preparing method and application thereof

A heat-resistant protective agent and freeze-drying technology, which can be used in freeze-dried transportation, antiviral agents, and pharmaceutical formulations, can solve the problems of less research and inconvenient production for vaccine companies, and achieve easy preparation, suitable for large-scale production, and formulation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

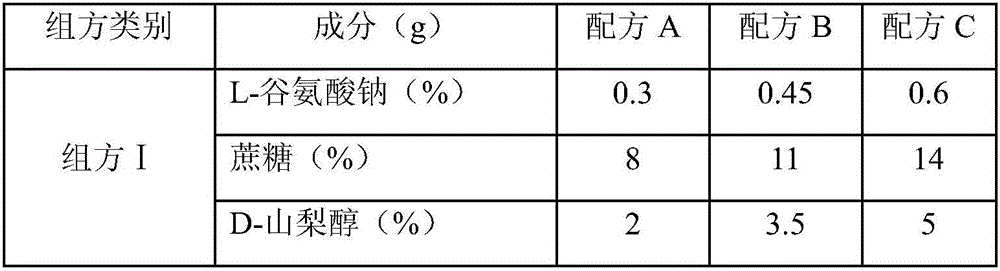

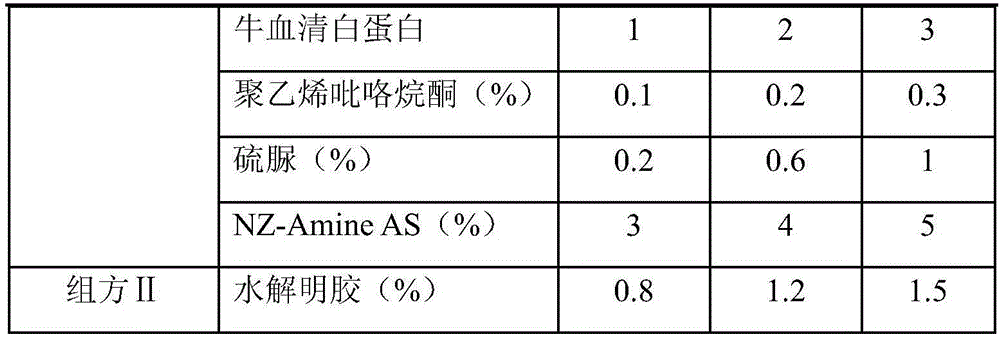

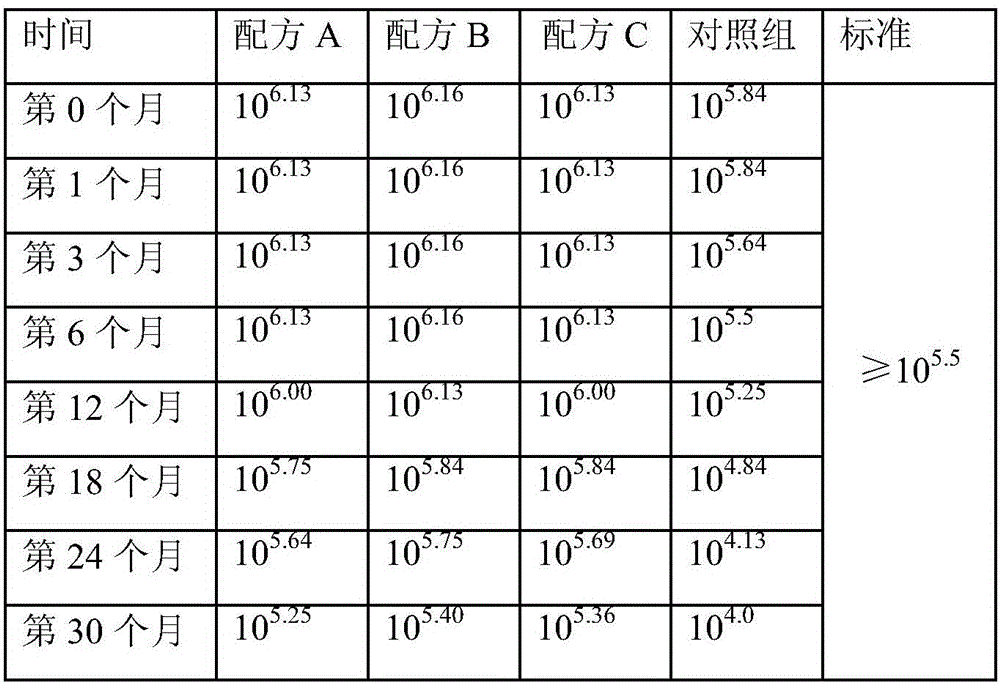

Method used

Image

Examples

Embodiment 1

[0035] 1. Cultivation and Harvest of Porcine Pseudomonas Virus

[0036] Passage and culture of Vero cells: When the Vero cells in the culture flask are covered with a single layer, discard the cell culture medium, and digest the cells with cell digestion solution containing 0.25% trypsin, and the digested cells in the culture flask are observed under an inverted microscope. When it becomes round and shrunk, immediately add cell growth solution to the culture flask, shake the culture flask to digest and disperse the cells into single cells, and culture the digested cells at a ratio of 1:3 for the next generation of cells.

[0037] Proliferation, culture and harvest of the virus: take the wet virus of PRV Bartha-k61 strain from the ultra-low temperature refrigerator at -70°C, inoculate the Vero cell culture bottle that has grown to a single layer at a ratio of 1% (V / V), and inoculate and continue to cultivate Observe and harvest when the cells have more than 80% lesions, freeze ...

Embodiment 2

[0062] 1. Culture and Harvest of Porcine Reproductive and Respiratory Syndrome Virus

[0063] Subculture and culture of cells: When the Marc-145 cells in the cell culture flask are covered with a monolayer, discard the growth medium, and digest the cells with 0.25% trypsin. The digested cells in the culture flask are round and shrunk when observed under an inverted microscope When it is in shape, immediately add cell growth solution to the culture flask, shake the culture flask to digest and disperse the cells into single cells, and expand the digested cells at a ratio of 1:4.

[0064] Proliferation, cultivation and harvest of the virus: Get the seed virus of PRRSV JXA1-R strain from the refrigerator at -70°C, and inoculate the Marc-145 cell culture bottle that has overgrown a single layer by a 0.5% (V / V) inoculation ratio. Continue to cultivate and observe, and harvest when the lesions of the cells reach more than 75%. Freeze and thaw the culture flask once at -20°C to collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com