Manufacturing process of fuel gas control valve used for fuel gas kitchenware

A manufacturing process and control valve technology, applied in the direction of manufacturing tools, valve details, multi-way valves, etc., can solve problems such as the inability to realize gas flow adjustment, affect the use of gas control valves, and pollute the casting process, achieving simple manufacturing process and low cost. Low, internal stress change balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

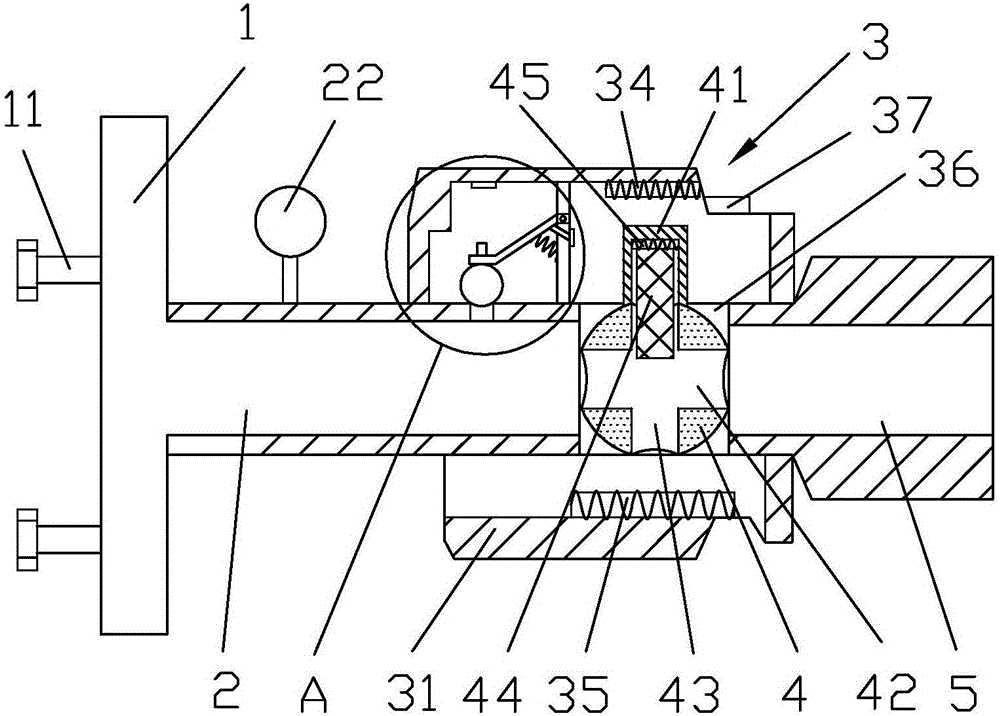

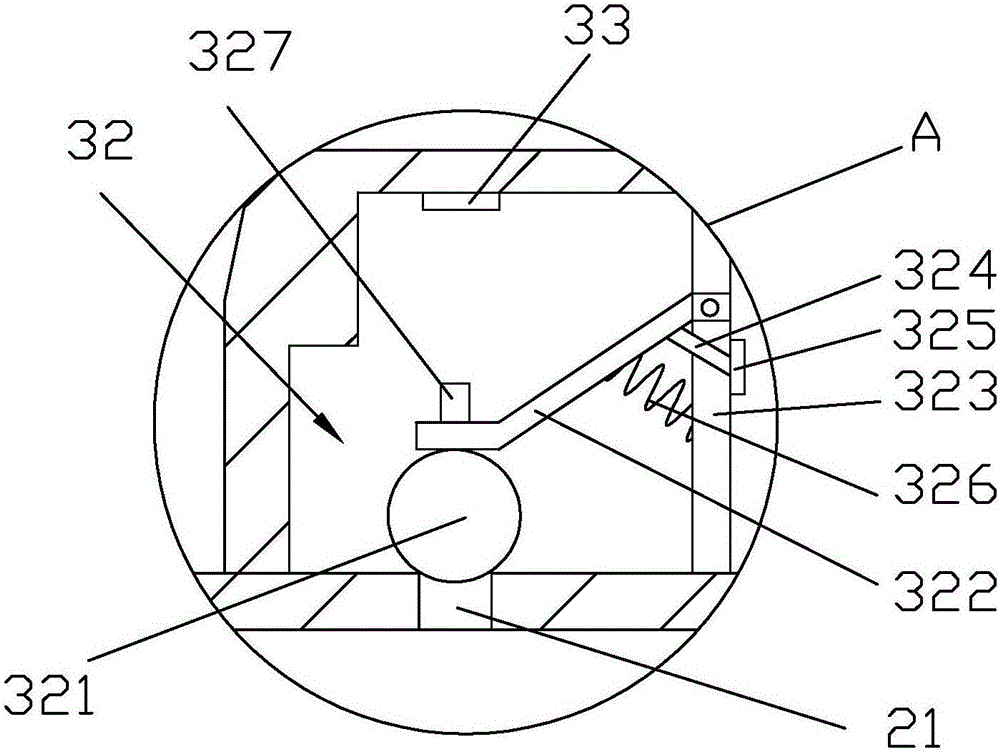

[0048] Such as Figure 1-2 As shown, the gas control valve manufacturing process for gas kitchen utensils of the present invention comprises the following steps:

[0049] 1) Make valve body 3:

[0050] a. Select a reasonable pouring position, pouring system and valve body 3 raw materials. The valve body 3 raw material is made of zinc alloy, and the valve body 3 is forged with zinc alloy, which has the function of pressure resistance and explosion protection;

[0051] b. Pour the raw materials used to make the valve body 3 into a sealed container, set a riser on the casting, install cold iron in the mold, and then pass in dry compressed air or inert gas to make the valve body 3 in the container Under the gas pressure, the raw materials pass through the riser pipe and the gating system from bottom to top, and enter the mold cavity smoothly to be cast. The molten metal that has not solidified in the channel returns to the container due to gravity, and finally the molten metal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com