Diatom mud negative ion dry powder coating material and preparation method thereof

A dry powder coating and diatom mud technology, applied in the field of coatings, can solve the problems of poor anti-mildew and sterilization ability, inability to release negative ions, poor coating strength and toughness, etc., to improve immunity, naturally and lastingly release negative ions, The effect of adjusting humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

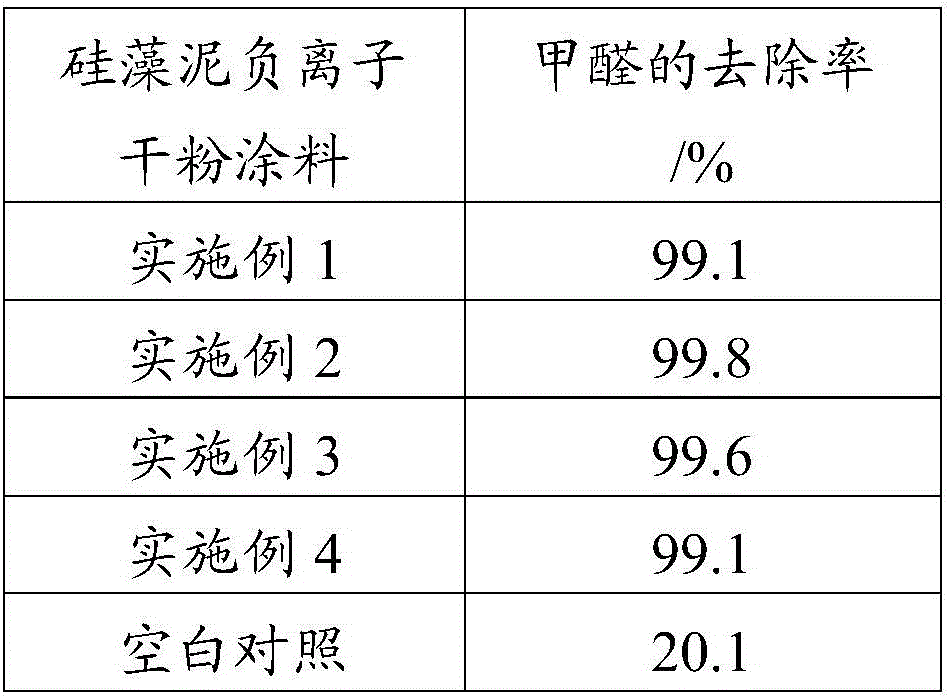

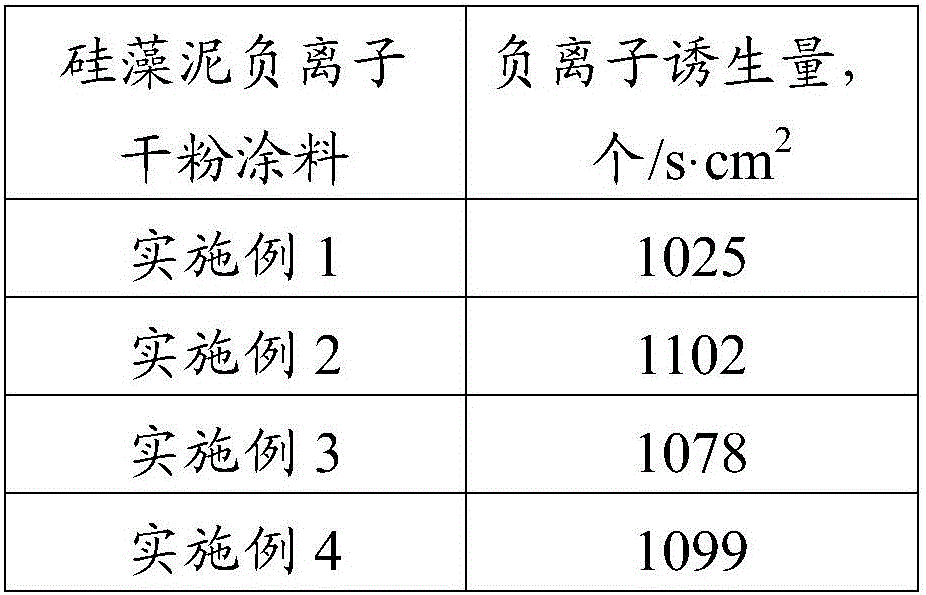

Examples

preparation example Construction

[0031] In the second aspect, the embodiment of the present invention also provides the preparation method of the above-mentioned coating, and its preparation method includes the following steps: according to the mass percentage of each component in the coating, heavy calcium powder, lime calcium powder, diatom ooze, negative ion additive, Antibacterial agent, anatase titanium dioxide, talcum powder, aluminum silicate, kaolin, wollastonite, surfactant, redispersible latex powder, modified seaweed powder are added to the mixer and stirred for 15-30min to obtain diatom Mud negative ion dry powder coating. Wherein, the stirring time may be 15 min, 17 min, 19 min, 21 min, 23 min, 25 min, 27 min, 30 min, etc.

[0032] The preparation method of the paint provided by the embodiment of the present invention has a simple process and less time-consuming, and is suitable for large-scale production and popularization.

Embodiment 1

[0036] The present embodiment provides a kind of diatom ooze negative ion dry powder coating, by mixing the following components in mass percentage: lime calcium powder 24.8%, diatom ooze 12.4%, negative ion additive 6.2%, silver-based inorganic composite antibacterial agent 4.1%, sharp Titanium type titanium dioxide 1.22%, talc powder 0.83%, aluminum silicate 0.83%, kaolin 0.40%, wollastonite 0.40%, hydroxyethyl cellulose 0.26%, ethylene-vinyl acetate copolymer rubber powder 0.83%, modified seaweed Glue powder 0.0040%, surplus is heavy calcium powder, and it is joined in the agitator and stirred 18min, can obtain the diatom ooze negative ion dry powder coating that present embodiment expects, and the average mesh number of this diatom ooze negative ion dry powder coating is 510 head.

[0037] Among them, the negative ion additive includes the following components in mass percentage: 35% of aluminum oxide, 10% of boron oxide, 2% of titanium dioxide, 1.2% of iron oxide, 0.6% of...

Embodiment 2

[0039] The present embodiment provides a kind of diatom ooze negative ion dry powder coating, by mixing the following components by mass percentage: lime calcium powder 25.36%, diatom ooze 12.67%, negative ion additive 6.34%, antibacterial agent 4.23%, anatase type titanium dioxide 1.27%, talc powder 0.85%, aluminum silicate 0.85%, kaolin 0.42%, wollastonite 0.42%, sodium carboxymethyl cellulose 0.25%, ethylene-vinyl acetate copolymer rubber powder 0.85%, modified alginate powder 0.0042 %, the balance is heavy calcium powder, and it is joined in the stirrer and stirred 20min, can obtain the diatom ooze negative ion dry powder coating that present embodiment expects, and the average order number of this diatom ooze negative ion dry powder coating is 540 orders.

[0040] Among them, the negative ion additive is an inorganic non-metal composite negative ion additive, including the following components in mass percentage: 37% of aluminum oxide, 11% of boron oxide, 3% of titanium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com