Corn and potato fried flour flavored fermented milk

A technology of fermented milk and fried noodles, applied in dairy products, applications, milk preparations, etc., can solve problems such as complex ingredients and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

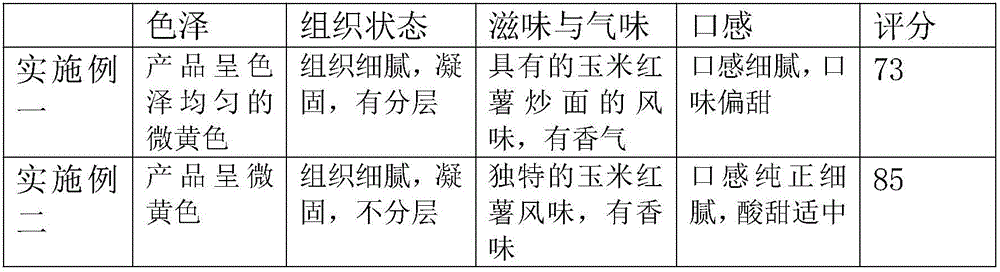

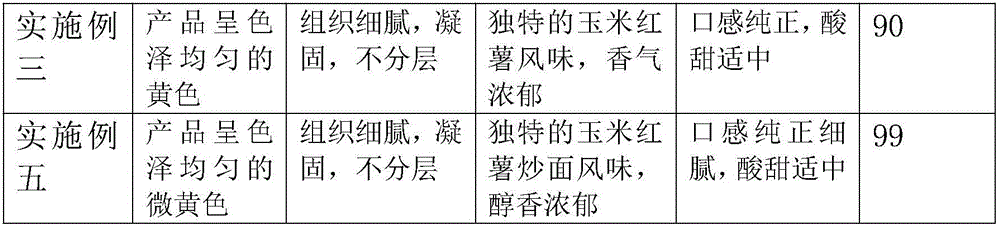

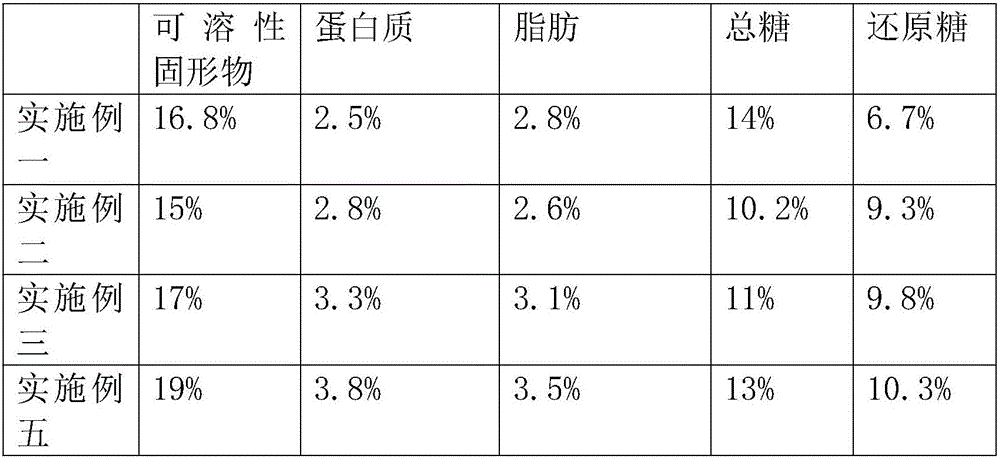

Examples

Embodiment 1

[0024] Embodiment 1: a kind of flavor fermented milk of sweet potato fried noodles, its preparation process is as follows:

[0025] 1) Raw material processing: preparation of cooked diced sweet potatoes, put the cleaned and peeled diced sweet potatoes into a steamer, steam at 120°C for 15 minutes, and then make mature diced sweet potatoes;

[0026] Preparation of cooked corn kernels, peeling and cleaning the corn kernels, soaking and cooking to obtain cooked corn kernels;

[0027] Add cooked diced sweet potatoes with 1 times the mass fraction of the cooked corn kernels, stir and mix evenly, then use a rotary drum dryer to fry for 20 minutes, then crush the fried materials and sieve them with a 120-mesh sieve, Store the screened materials for later use;

[0028] 2) Blending: Step 1) adding 6 parts by mass to 100 parts by mass of pure milk sieved corn and sweet potato noodles and 3 parts by mass of sucrose, then blending, and passing through a 100-mesh screen to remove slag;

...

Embodiment 2

[0035] Embodiment two: a kind of flavor fermented milk of sweet potato fried noodles, its preparation process is as follows:

[0036] 1) Raw material processing: preparation of cooked diced sweet potatoes, put the cleaned and peeled diced sweet potatoes into a steamer, steam for 15 minutes at a temperature of 125°C, and then make mature diced sweet potatoes;

[0037] Preparation of cooked corn kernels, peeling and cleaning the corn kernels, soaking and cooking to obtain cooked corn kernels;

[0038] Add 5 times the mass fraction of cooked sweet potato dices to 1 mass part of cooked corn kernels, stir and mix evenly, then use a rotary drum dryer to fry for 40 minutes, then crush the fried material and use a 120-mesh sieve Screening is carried out, and the screened materials are stored for later use;

[0039] 2) Blending: Step 1) adding 10 parts by mass of pure milk to 100 parts by mass of pure milk;

[0040] 3) Homogenization: preheat the mixture to 60°C, and then pass it thr...

Embodiment 3

[0046] Embodiment three: a kind of flavor fermented milk of sweet potato fried noodle, its preparation process is as follows:

[0047] 1) Raw material processing: preparation of cooked diced sweet potatoes, put the cleaned and peeled diced sweet potatoes into a steamer, steam at 130°C for 20 minutes, and then make mature diced sweet potatoes;

[0048] Preparation of cooked corn kernels, peeling and cleaning the corn kernels, soaking and cooking to obtain cooked corn kernels;

[0049] Add cooked diced sweet potatoes with 9 times the mass fraction of the cooked corn kernels, stir and mix evenly, then use a rotary drum dryer to fry for 40 minutes, then pulverize the fried materials and sieve them with a 120-mesh sieve. Store the screened materials for later use;

[0050] 2) Blending: Step 1) adding 15 parts by mass to 100 parts by mass of pure milk sieved corn sweet potato flour and 10 parts by mass of sucrose, then blending, and passing through a 100-mesh screen to remove slag;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com