Method for preparing antibacterial composite membrane, antibacterial composite membrane prepared from method and application thereof to field of water treatment

A composite membrane and heat treatment technology, applied in the field of separation membranes, can solve the problems of reducing silver ion release efficiency, shortening antibacterial life, reducing sterilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

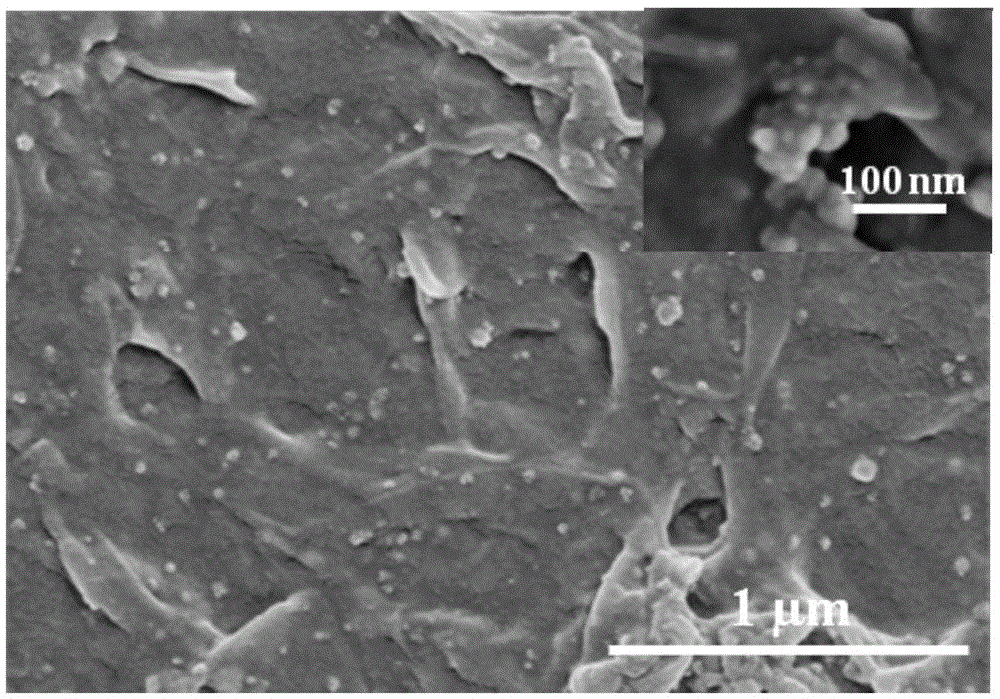

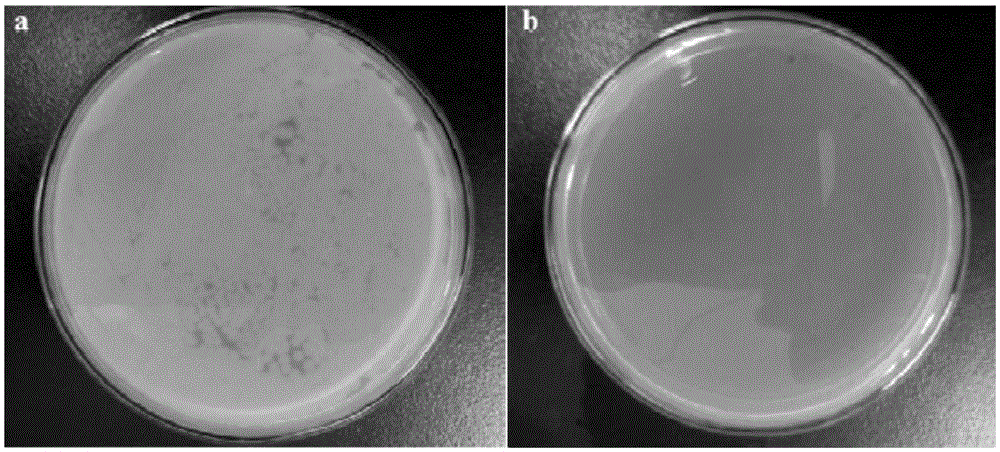

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of antibacterial composite membrane, and this method comprises the following steps:

[0024] (1) Mixing a polymer containing multiple hydroxyl groups, a silane coupling agent containing a mercapto group, an acid, an aldehyde, and a solvent to prepare a coating solution;

[0025] (2) coating the coating solution on a nanofiltration membrane or a reverse osmosis membrane to carry out a thermal crosslinking reaction to obtain a composite membrane with a crosslinked layer on the surface;

[0026] (3) the cross-linked layer of the composite membrane is contacted with an aqueous solution of silver nitrate;

[0027] (4) heat-treating the composite film obtained after step (3).

[0028] According to one embodiment of the present invention, in step (1), the polymer containing polyhydric hydroxyl can be one of polyvinyl alcohol, glucose, chitosan, sodium alginate and chitosan quaternary ammonium salt or more; preferably, the p...

Embodiment approach

[0042] According to one embodiment of the present invention, in the process of dissolving the polymer containing polyhydric hydroxyl group, aldehyde and silane coupling agent containing mercapto group in the solvent, it is preferably carried out under the condition of stirring. The conditions and stirring equipment are not specifically limited, and can be carried out under appropriate stirring conditions with conventional stirring equipment well known to those skilled in the art, as long as the polymers containing polyhydric hydroxyl groups, aldehydes, and silane coupling agents containing mercapto groups can be It can be fully dissolved in the solvent. In addition, in the present invention, the process of dissolving the polyhydric hydroxyl-containing polymer, aldehyde, and mercapto-containing silane coupling agent in a solvent may be carried out at normal temperature.

[0043] In a word, the present invention prepares the coating liquid by dissolving the polymer containing po...

Embodiment 1

[0062] This embodiment is used to illustrate the antibacterial composite film provided by the present invention and its preparation method.

[0063] (1) Preparation of PVA coating solution: Dissolve 1.0g of PVA in 100g of deionized water, heat to 90°C, stir until it is completely dissolved, then add 0.1g of formaldehyde and 0.4g of formaldehyde to the cooled above solution γ-mercaptopropyltrimethoxysilane, and then dropwise dropwise dilute hydrochloric acid under stirring conditions to adjust the pH of the solution to 1;

[0064] (2) Thermal crosslinking reaction: contact the surface of NF90 with polyamide dense layer polymerized on the surface with the PVA coating solution obtained above for 30s by coating, remove excess solution, and then put it in an oven at 100°C for crosslinking After 6min, a composite film with a cross-linked PVA structure on the surface was obtained;

[0065] (3) The composite film is coated with one side of PVA layer and 2% by weight of AgNO 3 The aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com