Preparation method of oxidized graphene coated Ni-Co alloy particle composite material

A technology of graphene coating and composite materials, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of narrow absorption frequency band, poor impedance matching characteristics, and limited use range, etc., to achieve improved impedance matching and good temperature stability , Improve the effect of complex permittivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

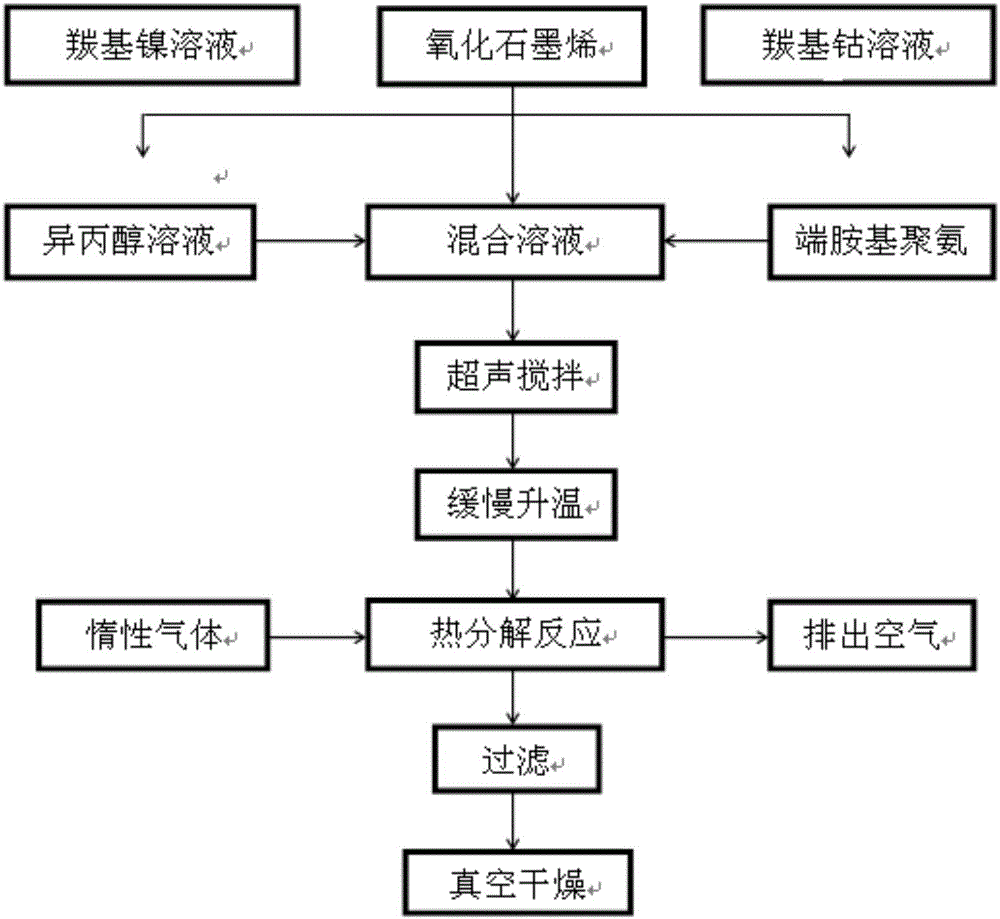

[0029] Step 1: Weigh 3.41g of nickel carbonyl and 3.42g of cobalt carbonyl and dissolve them in 50mL of isopropanol and 1mL of amino-terminated polyurethane in an aqueous solution; then add 1mL of γ-aminopropyltriethoxysilane as a surface treatment agent for the mixed particles , Ultrasonic dispersion for 0.5h, to obtain a uniformly mixed nickel carbonyl and cobalt carbonyl mixed solution.

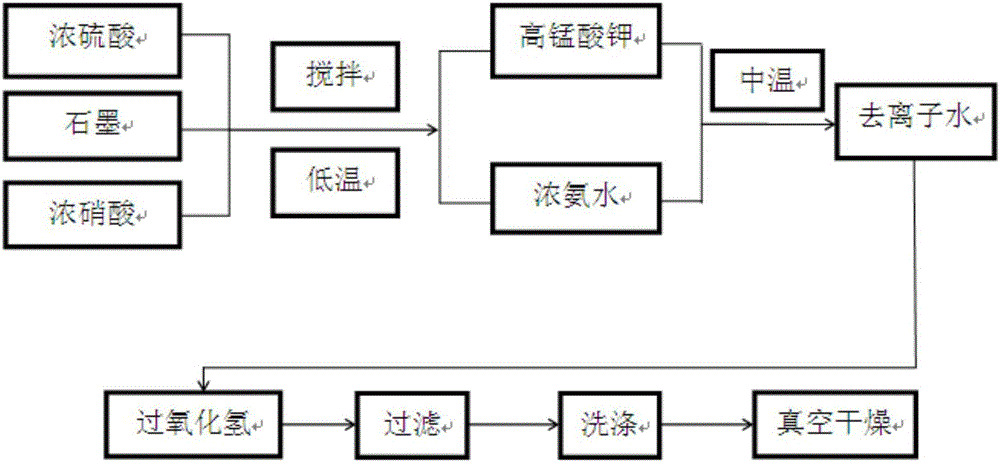

[0030] Step 2: Weigh 2g graphite powder and place it in a 250mL beaker, add 10mL concentrated nitric acid, 5mL concentrated sulfuric acid, then add 5g potassium permanganate, ultrasonically disperse for 10min, wash with deionized water three times, add 5mL concentrated ammonia water and ultrasonically disperse for 10min, After centrifugal washing for 2 times, add 10mL hydrogen peroxide solution and ultrasonically disperse for 10min, centrifuge and wash twice, add 5mL concentrated hydrochloric acid and ultrasonically disperse for 10min, wash twice, then add 10mL absolute ethanol and ultrason...

Embodiment 2

[0040] Step 1: Weigh 6.82g of nickel carbonyl and 6.84g of cobalt carbonyl and dissolve them in 100mL of isopropanol and 2mL of amino-terminated polyurethane in an aqueous solution to obtain a mixed solution; then add 1mL of γ-aminopropyltriethoxysilane as mixed particles surface treatment agent, and ultrasonically disperse for 0.5h to obtain a mixed solution of nickel carbonyl and cobalt carbonyl that is uniformly mixed.

[0041]Step 2: Weigh 4g of graphite powder into a 500mL beaker, add 20mL of concentrated nitric acid, 10mL of concentrated sulfuric acid, then add 10g of potassium permanganate, ultrasonically disperse for 20min, wash with deionized water three times, add 10mL of concentrated ammonia water and ultrasonically disperse for 10min, After centrifugal washing for 2 times, add 20mL hydrogen peroxide solution and ultrasonically disperse for 10min, centrifugally wash twice, add 10mL concentrated hydrochloric acid and ultrasonically disperse for 10min, wash twice, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com