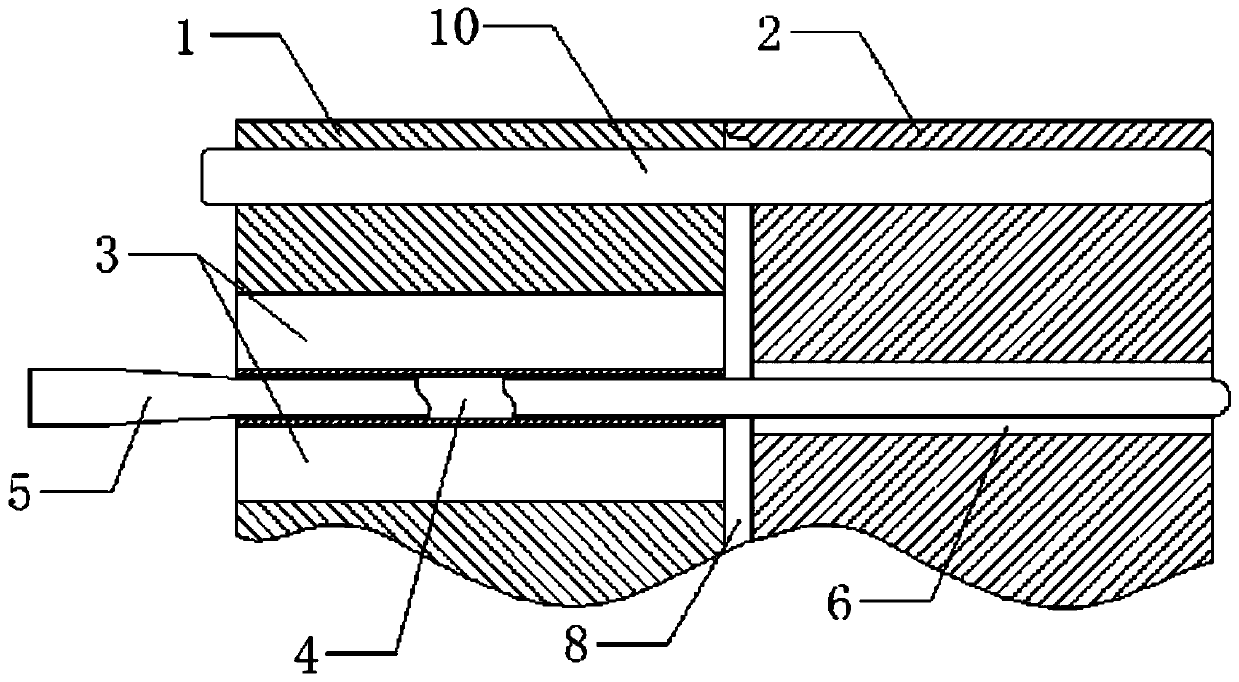

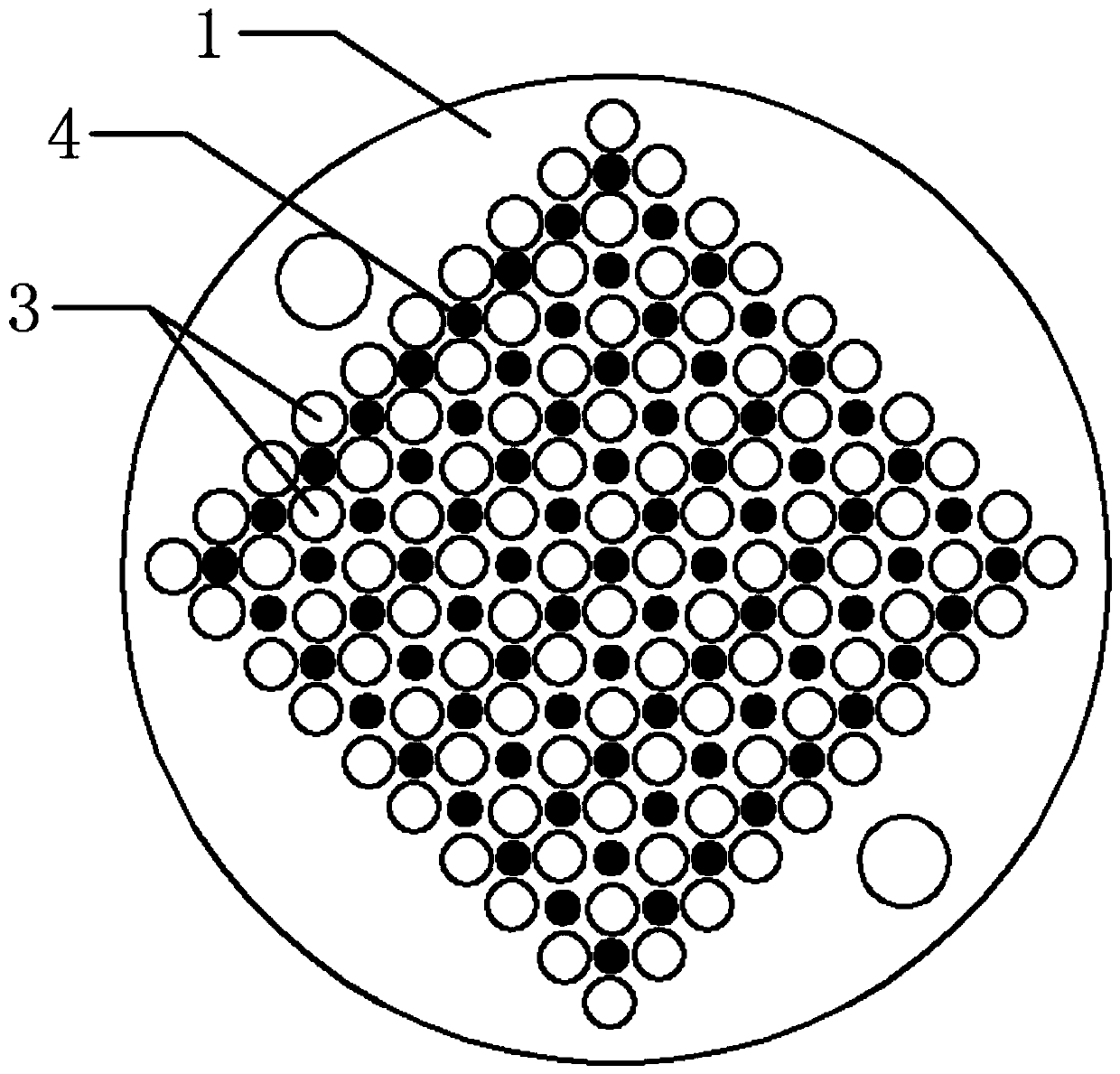

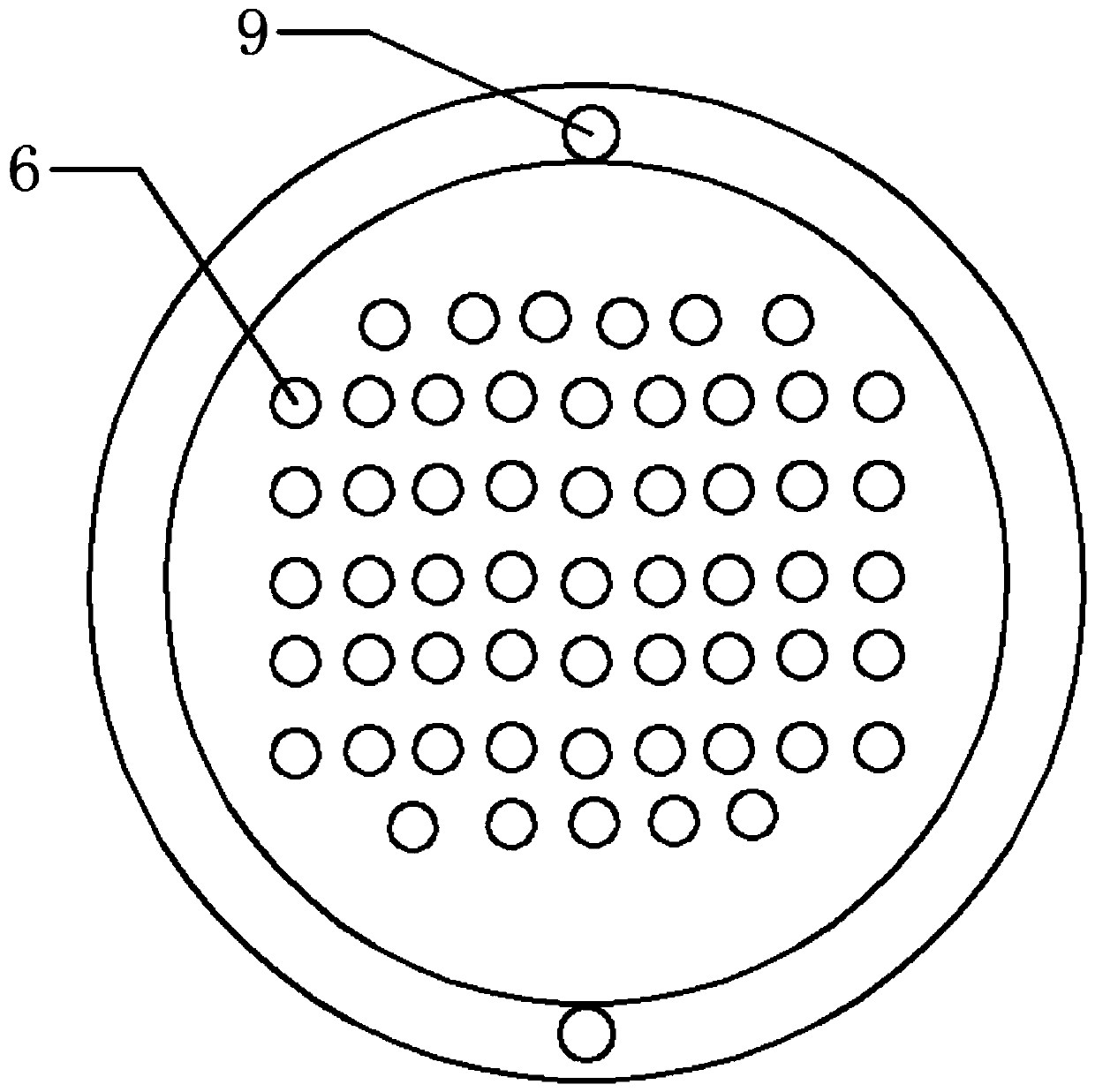

A micro catalyst carrier mold, the manufacturing process of the mold and the method of preparing the carrier by using the mold

A catalyst carrier and mold technology, applied in the field of micro-catalyst carrier molds, can solve problems such as disadvantage and low strength of catalyst carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0090] Example 1, alumina catalyst carrier manufacturing steps

[0091] (1). Select commercially available pseudo-boehmite produced by a certain company and macroporous aluminum hydroxide powder produced by a certain company as raw materials. The specific surface of pseudo-boehmite is 200-250m2 / g, the pore volume is 0.2-0.4ml / g, and the average pore diameter is 6-8nm; the specific surface of macroporous aluminum hydroxide powder is 250-350m2 / g, and the pore volume is 0.7 ~1.5ml / g, the average pore size is 12~20nm;

[0092] (2). The weight ratio is Pseudoboshemite: macroporous aluminum hydroxide = 80:20. 200kg of mixing main ingredients, i.e. 160kg of pseudo-boehmite, 40kg of large-aperture aluminum hydroxide powder, plus 1.5% carboxymethyl cellulose (CMC) as the binder, i.e. 3kg of CMC;

[0093] (3). Put the powder in step (2) into the screw mixer, mix for 20 minutes and take it out for use;

[0094] (4). Put 6 kg of 3% nitric acid of the main ingredient into deionized wate...

example 2

[0106] Example 2, molecular sieve catalyst carrier product production steps

[0107] (1) Select aluminum sol dry powder produced by a certain company and SAPO-11 molecular sieve raw powder produced by a certain company. The chemical molecular formula of aluminum sol is a(Al2O3·nH2O)·bHx·cH2O, in which: Al2O3·nH2O is hydrated alumina, Hx is peptizer, coefficient: b<a, c, n, this aluminum sol has adhesiveness, Thixotropy, easy dispersibility, water-soluble reversibility, suspension, stability and other characteristics; SAPO-11 molecular sieve has AEL structure, which belongs to orthorhombic crystal system, and its skeleton is mainly formed by interweaving A1O2-, PO2+, SiO2 tetrahedrons. Elliptical ten-membered ring with one-dimensional straight channel, which has high activity and selectivity in reactions such as n-butene isomerization and long-chain n-alkane hydroisomerization, and can improve gasoline octane number and lubricating oil hydrogenation in catalytic cracking It ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com