City-life-sludge resource utilization technology

A technology for urban domestic sludge and resource utilization, which is applied in the field of urban domestic sludge resource utilization technology, can solve the problems of secondary pollution, high energy consumption, poor economic benefits, etc., and achieves the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

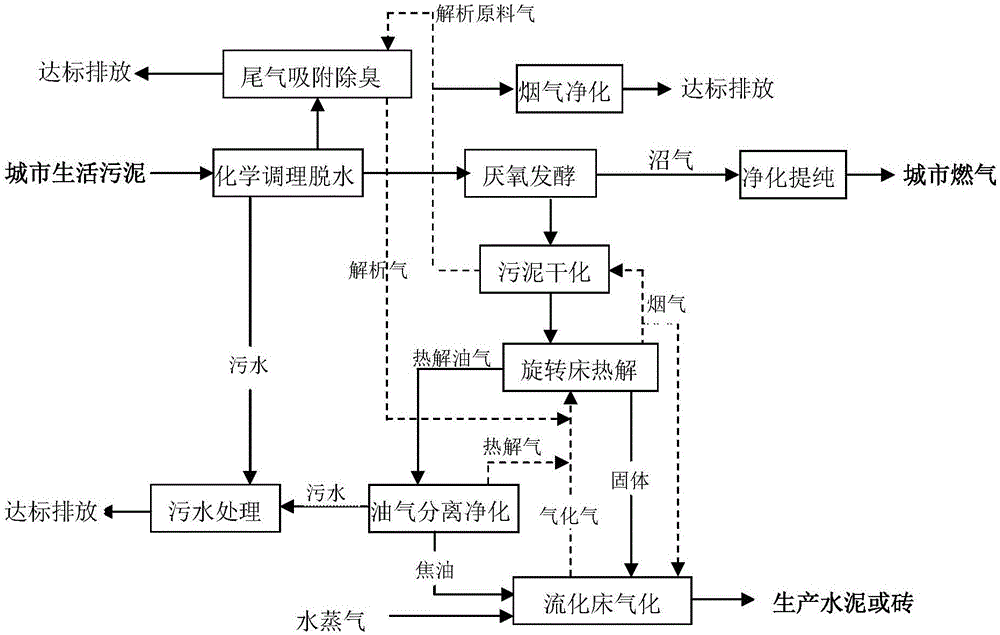

[0043] The sludge resource utilization process of the present invention, such as figure 1 shown. Put the treated sludge of urban domestic sewage into the mixing tank, add ferric chloride and polyferric sulfate to it, and send it to filter plate for dehydration after stirring. After dehydration, the water content in the sludge is reduced to 50%. An air inlet is set above the stirring tank and the filter press plate, and the emitted odor is sent to the adsorption and deodorization device equipped with activated carbon. The adsorption device is set up with two towers, one tower for adsorption and the other tower for regeneration. After the adsorbent is saturated, it is used for subsequent pyrolysis flue gas regeneration, and then blows with air cold, and the two towers are alternately performed.

[0044] After chemical conditioning and dehydration, the sludge is sent to the fermenter for anaerobic fermentation through the conveying device. The fermentation temperature is 40°C, t...

Embodiment 2

[0050] The sludge resource utilization process of the present invention, such as figure 1 shown. Put the treated sludge of urban domestic sewage into the mixing tank, add polyacrylamide to it, and send it to filter plate for dehydration after stirring. After dehydration, the water content in the sludge is reduced to 60%. An air inlet is set above the filter plate to send the emitted odor to the adsorption deodorization device equipped with alumina. The adsorption device is set up with two towers, one tower for adsorption and the other tower for regeneration. After the adsorbent is saturated, it is used for subsequent pyrolysis flue gas regeneration, and then blows with air cold, and the two towers are alternately performed.

[0051] After chemical conditioning and dehydration, the sludge is sent to the fermenter for anaerobic fermentation through a conveying device. The fermentation temperature is 70°C, the fermentation time is 5 days, and the stirring frequency is 8h / time. T...

Embodiment 3

[0057] The sludge resource utilization process of the present invention, such as figure 1 shown. Put the treated sludge of urban domestic sewage in the mixing tank, add polyacrylamide to it, and send it to filter plate for dehydration after stirring. After dehydration, the water content in the sludge is reduced to 55%. An air inlet is set above the filter plate to send the emitted odor to the adsorption deodorization device equipped with silica gel and molecular sieve. The adsorption device is set up with two towers, one tower for adsorption and the other tower for regeneration. After the adsorbent is saturated, it is used for subsequent pyrolysis flue gas regeneration, and then blows with air cold, and the two towers are alternately performed.

[0058] After chemical conditioning and dehydration, the sludge is sent to the fermenter for anaerobic fermentation through the conveying device. The fermentation temperature is 60°C, the fermentation time is 4 days, and the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com