Efficient energy-saving insulation material and preparation method thereof

A technology of high-efficiency energy-saving and thermal insulation materials, applied in ceramic products, other household appliances, applications, etc., can solve the problems of complex construction technology, pollution of the environment, poor fire resistance, etc., and achieve simple processing technology, low thermal conductivity, and good heat insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

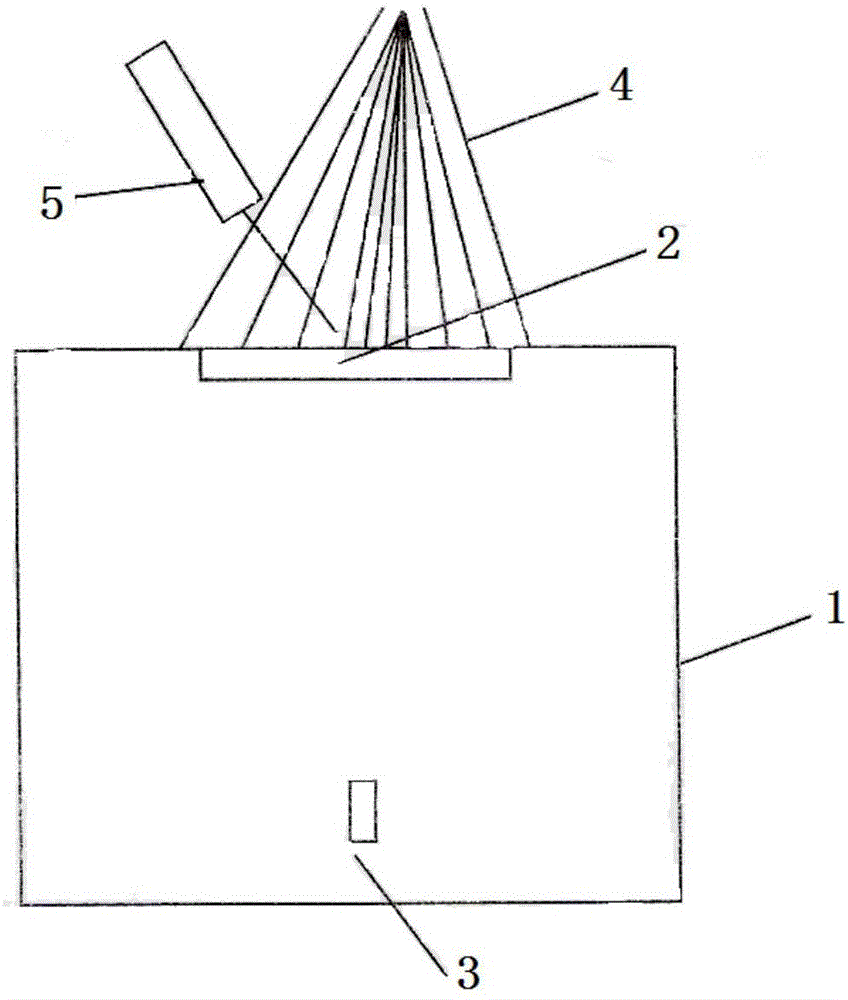

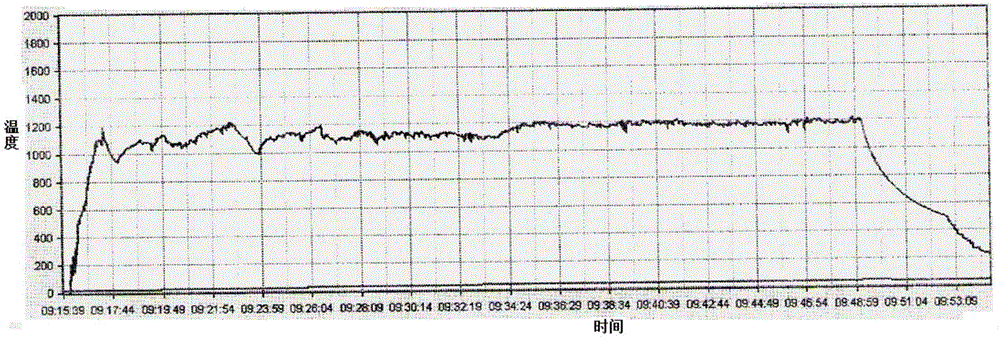

Image

Examples

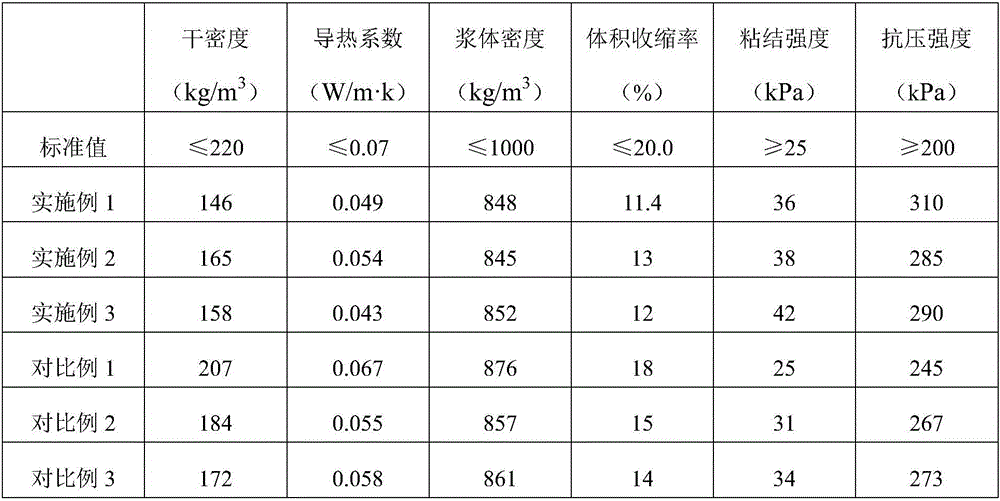

Embodiment 1

[0045] Prepare ingredients:

[0046] 450kg of water, 220kg of perlite powder, 15kg of sodium silicate, 35kg of aluminum silicate cotton, 20kg of sepiolite powder, 0.3kg of white clay powder, 0.2kg of bentonite, 0.5kg of cooked rubber powder I, 0.3kg of cooked rubber powder II, cellulose 0.5kg, toluene diisocyanate 3kg, flame retardant 8kg, polyacrylamide powder 0.5kg, polyvinyl alcohol powder 0.3kg, aluminum phosphate 0.3kg.

[0047] Preparation of high-efficiency energy-saving insulation materials

[0048] (1) Add 35kg of aluminum silicate wool and 0.5kg of cellulose into 450kg of water and soak for 48 hours;

[0049] (2) Add the soaking solution of step (1) into a vortex mixer, fully stir for 1 hour, and form a snowflake shape;

[0050] (3) Add 0.5kg polyacrylamide powder and continue to stir for 0.5 hours;

[0051] (4) Add 0.3kg aluminum phosphate, 15kg sodium silicate, 20kg sepiolite powder, 0.3kg white clay powder, 0.2kg bentonite, 0.5kg cooked rubber powder I, 0.3kg c...

Embodiment 2

[0055] Prepare ingredients:

[0056]480kg of water, 250kg of perlite powder, 16kg of sodium silicate, 36kg of aluminum silicate cotton, 25kg of sepiolite powder, 0.4kg of white clay powder, 0.2kg of bentonite, 0.5kg of cooked rubber powder I, 0.3kg of cooked rubber powder II, cellulose 0.6kg, diphenylmethane diisocyanate 3kg, flame retardant 10kg, polyacrylamide powder 0.5kg, polyvinyl alcohol powder 0.3kg, aluminum phosphate 0.4kg.

[0057] Preparation of high-efficiency energy-saving insulation materials

[0058] (1) Add 36kg of aluminum silicate cotton and 0.6kg of cellulose into 480kg of water and soak for 48 hours;

[0059] (2) Add the soaking solution of step (1) into a vortex mixer, fully stir for 1 hour, and form a snowflake shape;

[0060] (3) Add 0.5kg polyacrylamide powder and continue to stir for 0.5 hours;

[0061] (4) Add 0.4kg aluminum phosphate, 16kg sodium silicate, 25kg sepiolite powder, 0.4kg white clay powder, 0.2kg bentonite, 0.5kg cooked rubber powder ...

Embodiment 3

[0065] Prepare ingredients:

[0066] 420kg of water, 210kg of perlite powder, 12kg of sodium silicate, 33kg of aluminum silicate cotton, 18kg of sepiolite powder, 0.3kg of white mud powder, 0.1kg of bentonite, 0.3kg of cooked rubber powder I, 0.3kg of cooked rubber powder II, cellulose 0.5kg, toluene diisocyanate 4kg, flame retardant 5kg, polyacrylamide powder 0.25kg, polyvinyl alcohol powder 0.25kg, aluminum phosphate 0.25kg.

[0067] Preparation of high-efficiency energy-saving insulation materials

[0068] (1) Add 33kg of aluminum silicate wool and 0.5kg of cellulose into 420kg of water and soak for 48 hours;

[0069] (2) Add the soaking solution of step (1) into a vortex mixer, fully stir for 1 hour, and form a snowflake shape;

[0070] (3) Add 0.25kg of polyacrylamide powder and continue to stir for 0.5 hours;

[0071] (4) Add 0.25kg aluminum phosphate, 12kg sodium silicate, 18kg sepiolite powder, 0.3kg white clay powder, 0.1kg bentonite, 0.3kg cooked rubber powder I, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com