Alkali excitation fly ash dry mixing heat insulation plate bonding mortar and preparation method thereof

A technology for bonding mortar and fly ash, which is applied in the field of alkali-excited fly ash dry-mixed thermal insulation board bonding mortar and its preparation, can solve the problems of few manufacturers, great strength drop, and high cost of high-alumina cement, and achieves the reduction of The utilization of non-renewable resources, the effect of solving the large amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare raw materials according to the following components and weights: 20kg of fly ash, 7kg of ordinary Portland cement with a cement strength grade of 32.5, 3kg of heavy calcium powder, 40kg of 50-mesh coarse sand, 0.8kg of vinyl acetate and ethylene copolymer rubber powder, viscosity It is 0.03kg of hydroxypropyl methylcellulose ether of 60000mPa.s, 0.03kg of wood fiber with a length of 200μm, 5kg of sodium silicate, 1.2kg of sodium hydroxide, 0.01kg of glass fiber with a length of 6mm, and powdered cationic polymer. Carboxylic acid water reducing agent 0.3kg;

[0027] After measuring each component according to the proportion, mix it in the dry mixing equipment for 3 minutes to obtain the bonding mortar of the thermal insulation board. When in use, add clean water with 19% of the mass of the insulation board bonding mortar, mix and stir for 2 minutes to obtain the alkali-activated fly ash dry-mix insulation board bonding mortar, and the construction can be done.

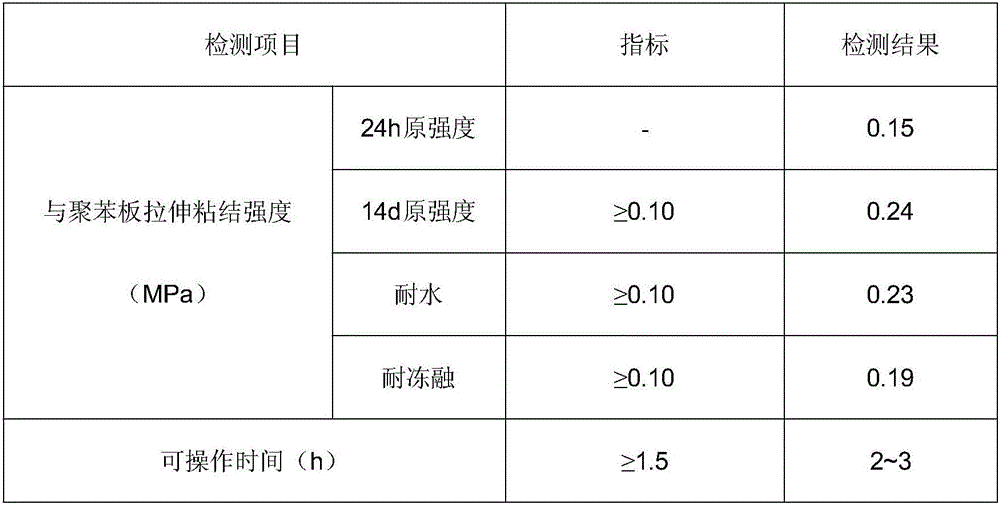

...

Embodiment 2

[0031] 25kg of fly ash, 7kg of slag Portland cement with a strength grade of 42.5, 3kg of heavy calcium powder, 40kg of 40-mesh dried river sand, 0.8kg of acrylate and styrene copolymer powder, hydroxyethyl alcohol with a viscosity of 80000mPa.s 0.03kg of methyl cellulose ether, 0.03kg of wood fiber with a length of 300μm, 6kg of sodium silicate, 1.3kg of sodium hydroxide, 0.01kg of polypropylene with a length of 8mm, 0.3kg of powder cationic polycarboxylate water reducer .

[0032] After measuring each component according to the proportion, mix in dry mixing equipment for 4 minutes to obtain thermal insulation board bonding mortar. When in use, add water with 20% of the mass of the insulation board bonding mortar, mix and stir for 2.5 minutes to obtain the alkali-activated fly ash dry-mix insulation board bonding mortar, and the construction can be done.

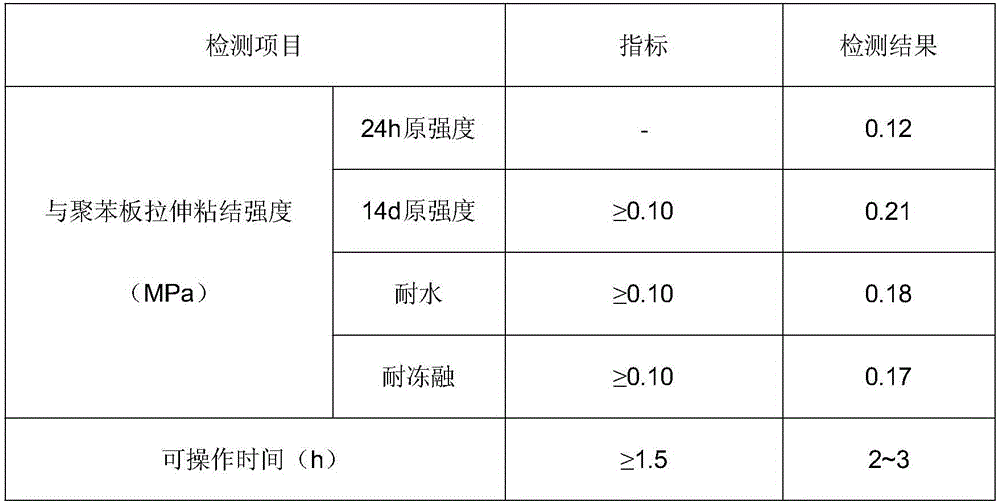

[0033] The performance test results of the insulation board bonding mortar are as follows:

[0034]

Embodiment 3

[0036] 30kg of fly ash, 10kg of heavy calcium powder, 40kg of 60-mesh coarse sand, 1.0kg of styrene and diene copolymerized rubber powder, 0.03kg of cellulose ether with a viscosity of 100000mPa.s, 0.03kg of wood fiber with a length of 500μm, silicic acid 10kg sodium, 1.5kg sodium hydroxide, 0.01kg polyacrylonitrile fiber with a length of 10mm, 0.3kg powder cationic polycarboxylate water reducer

[0037] After measuring each component according to the proportion, mix it in dry mixing equipment for 5 minutes to obtain thermal insulation board bonding mortar. When in use, add water with 21% of the mass of the insulation board bonding mortar, mix and stir for 3 minutes to obtain the alkali-activated fly ash dry-mix insulation board bonding mortar, and the construction can be done.

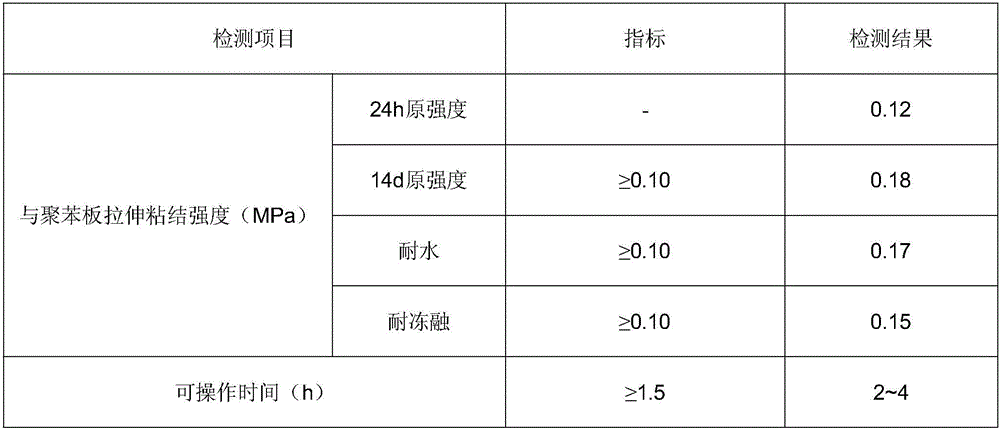

[0038] The performance test results of the insulation board bonding mortar are as follows:

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com