A kind of preparation method of copper glycinate

A technology of copper glycinate and glycine, applied in the field of preparing copper glycinate by ammonia catalysis method, can solve the problems of difficult purification and long reaction time, and achieve the effects of accelerating sedimentation speed, increasing yield and speeding up separation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

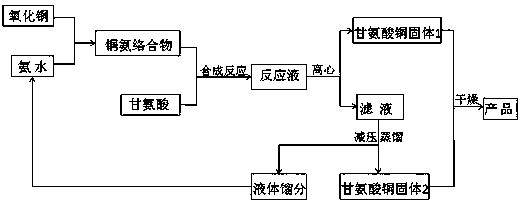

[0028] The preparation method of copper glycinate in the present invention is described in further detail below, including the following steps:

[0029] ① Dissolution of copper oxide: According to the ratio of the reaction molar ratio of copper oxide to ammonia of 1:2 to 1:10, the copper oxide is dissolved in ammonia water with a mass fraction of 5% to 50% to form a copper-ammonia complex;

[0030] CuO+4NH 3 ·H 2 O→Cu(NH 3 ) 4 (OH) 2 +3H 2 O

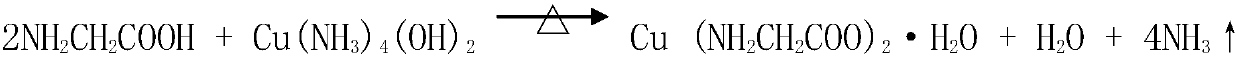

[0031] ② Synthesis reaction: Put the glycine and copper ammonia complex into the reaction according to the reaction molar ratio of 1:1 to 3:1, the heating temperature is 30 to 100 ℃, and the reaction is 30 to 200 min to obtain the reaction liquid;

[0032]

[0033] ③Product purification: the above reaction solution was cooled to 20-50℃, centrifuged to obtain copper glycinate solid 1 and filtrate, and then the filtrate was distilled under reduced pressure to obtain copper glycinate solid 2 and liquid fraction. The pressure of vacuum distillation w...

Embodiment 1

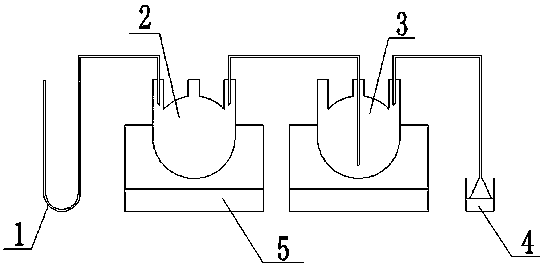

[0038] Such as figure 2 As shown, add 8g of copper oxide and 100ml of 15% ammonia water to the reaction flask 2, stir for 40 minutes and then completely dissolve, then add 15g of glycine and slowly heat it. At the same time, add 70ml of water and 8g of oxidation to the ammonia recovery flask 3. Copper, stir with magnetic stirrer 5 at room temperature. As the reaction temperature rises, the ammonia gas that is slowly generated in the reaction flask 2 reacts with glycine, and at the same time; the ammonia that overflows from the reaction flask 2 enters the ammonia recovery flask 3 to form cupric ammonia complexes with copper oxide The residual ammonia gas is absorbed by the tail gas treatment device 4. By observing the liquid level difference of the U-tube differential pressure gauge 1 to determine the pressure in the system, the reaction temperature can be adjusted to control the ammonia generation rate. After the reaction for 90 minutes, the reaction temperature rose to 90°C...

Embodiment 2

[0040] Add another 16g of copper oxide to the ammonia recovery bottle 3 in Example 1, and slowly add 125ml of 25% ammonia water as a new round of reaction flask 2. Stir fully for 50 minutes to completely dissolve the copper oxide and add 45g of glycine Then slowly heat up, and at the same time, add all the liquid fractions obtained by distillation under reduced pressure in Example 1 to the clean ammonia recovery bottle 3 and add deionized water to 210ml. At the same time, add 24g of copper oxide and stir at room temperature for Absorb the ammonia generated in the reaction flask 2, and observe the liquid level difference of the U-tube differential pressure gauge 1 to determine the pressure in the system. The reaction temperature can be adjusted to control the ammonia generation rate. After reacting for 120 minutes, the reaction temperature rose to 95°C, and there was almost no gas generation in the reaction flask 2, the reaction was stopped, the reaction solution was cooled to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com