Carbon fiber health latex

A technology of carbon fiber and carbon fiber powder, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low share, single product performance, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

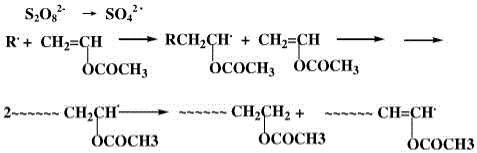

Method used

Image

Examples

example ( 1

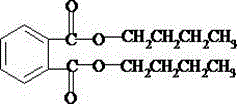

[0061] (1) Optimum ratio: vinyl acetate 30%, polyvinyl alcohol 4%, dibutyl phthalate 4%, octanol 1%, ammonium persulfate 0.1-1%, carbon fiber powder 0.3%, jade powder 5%, negative ion powder 5%, sepiolite powder 5%, germanite powder 5%, water 40%.

[0062] (2) Dissolve polyvinyl alcohol powder in deionized water completely, and filter (PVA-1788 2488, etc. can be used).

[0063] (3) Put the polyvinyl alcohol glue into the stainless steel reaction kettle (the enamel reaction kettle can also be used, but the heat transfer effect of the enamel kettle is not as good as that of the stainless steel reaction kettle), then add the emulsifier OP-10, and start the mixer to mix it evenly.

[0064] (4) Add 15% (i.e. 6.9) of the total amount of polyvinyl acetate monomer and 40% (i.e. 0.036) of the formula amount of potassium persulfate into the stainless steel reactor, continue to stir, and start to heat up; when the temperature rises to 60 Stop heating at -65°C; it should be noted that th...

example ( 2

[0072] (1) Optimum ratio: vinyl acetate 30%, polyvinyl alcohol 4%, dibutyl phthalate 4%, octanol 1%, ammonium persulfate 0.1-1%, jade powder 5%, negative ion powder 5%, sepiolite powder 5%, germanite powder 5%, water 40%.

[0073] (2) Dissolve the polyvinyl alcohol powder in deionized water completely, and filter. (Optional PVA-1788 2488, etc.).

[0074] (3) Put the polyvinyl alcohol glue into the stainless steel reaction kettle (the enamel reaction kettle can also be used, but the heat transfer effect of the enamel kettle is not as good as that of the stainless steel reaction kettle), then add the emulsifier OP-10, and start the mixer to mix it evenly.

[0075] (4) Add 15% (i.e. 6.9) of the total amount of polyvinyl acetate monomer and 40% (i.e. 0.036) of the formula amount of potassium persulfate into the stainless steel reactor, continue to stir, and start to heat up; when the temperature rises to 60 Stop heating at -65°C; it should be noted that the initiator potassium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com