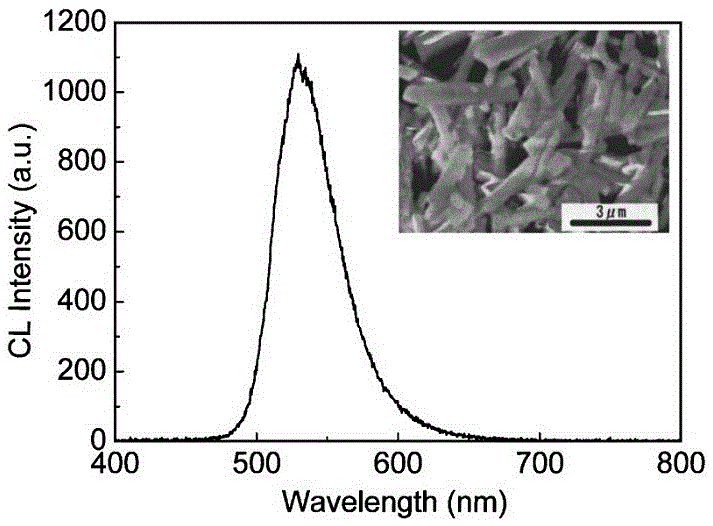

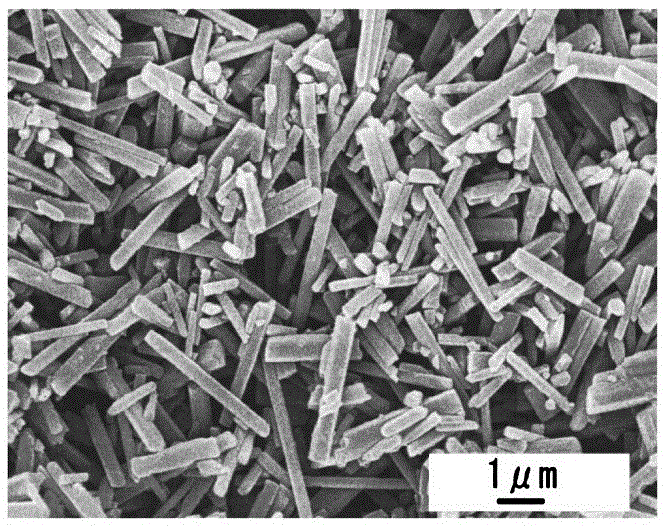

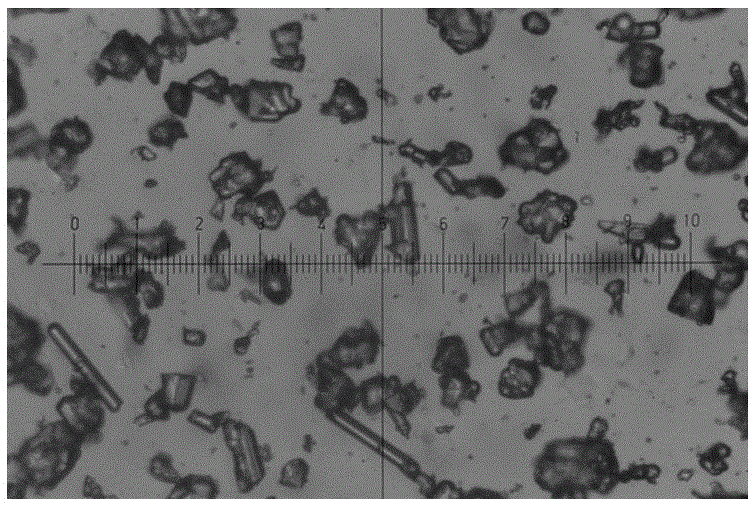

High-brightness large-particle-size beta-SiAlON:Eu<2+> green emitting phosphor and preparation method thereof

A green phosphor, large particle technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of insufficient brightness, uneven particle size, small particle size, etc., to achieve uniform particles, wide process window, and large average particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] β-SiAlON:Eu 2+ Preparation of green phosphor powder:

[0047] (1) Using α-Si 3 N 4 , AlN, Al 2 o 3 , Ga 2 o 3 、Eu 2 o 3 As raw material, according to the molar ratio of α-Si 3 N 4 :AlN:Al 2 o 3 : Ga 2 o 3 : Eu 2 o 3 =1.4:0.08:0.025:0.01:0.03 Weighing;

[0048] Note: Weighing of all the above raw materials must be carried out in the glove box N 2 Carried out under atmosphere (water content<1ppm, oxygen content<1ppm).

[0049] (2) Place the weighed raw material in a corundum mortar and grind it in one direction for 0.5h to fully mix the raw material, then pass through a 50-mesh sieve, and put it into a BN crucible.

[0050] (3) Primary sintering: Put the BN crucible into a high-temperature pressure sintering furnace, first pump the air with the mechanical pump to below 10Pa, turn on the molecular pump to pump air to the order of 10E-2, perform two times of air washing, and preheat to 500 °C , and then filled with N at a rate of 12MPa / h 2 :H 2 = 9:1 ra...

Embodiment 2~4

[0055] With reference to Example 1, change N in step (3) 2 / H 2 The ratio of the mixed atmosphere and other process conditions remained unchanged, and the brightness of the material after one sintering was measured, and the results are shown in Table 1. The primary material in the table refers to the primary sintered material obtained after one sintering, and the corresponding brightness is also the brightness of the primary sintered material.

[0056] Table 1:

[0057] Example β-SiAlON:Eu 2+ green phosphor h 2 :N 2 brightness Example 1 primary material 1:9 43.2 Example 2 primary material 1:19 32.5 Example 3 primary material 1:4 12.5 Example 4 primary material Pure N 2 23.4

Embodiment 5~9

[0059] Referring to Example 1, only the primary sintering time in step (3) was changed, and other parameters and conditions remained unchanged, and the brightness of the material after primary sintering was measured, and the results are shown in Table 2. The primary material in the table refers to the primary sintered material obtained after one sintering, and the corresponding brightness is also the brightness of the primary sintered material.

[0060] Table 2:

[0061] Example β-SiAlON:Eu 2+ green phosphor Primary sintering time (h) brightness Example 1 primary material 6 43.2 Example 5 primary material 1 5.6 Example 6 primary material 4 23.5 Example 7 primary material 8 44.1 Example 8 primary material 10 32.5 Example 9 primary material 12 30.8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com