Method for directly preparing vanadium oxide from vanadium-containing liquid

A vanadium oxide and vanadium liquid technology, which is applied in the fields of hydrometallurgy and vanadium chemical industry, can solve the problems of low conversion rate of raw materials, low product purity, complicated preparation process, etc., and achieves simplified process flow, reduced reagent consumption, and energy saving. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

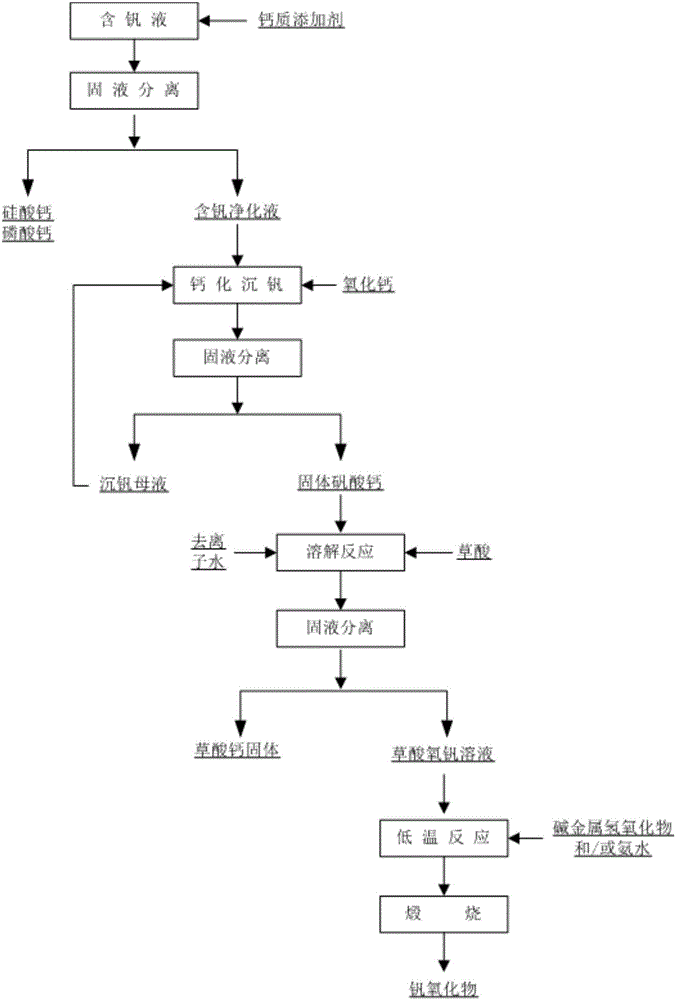

[0051] This embodiment provides a method for directly preparing vanadium oxides from a vanadium-containing liquid, the method comprising the following steps:

[0052] (1) Add calcium additives to the vanadium-containing liquid of sodium roasting-water leaching vanadium-containing liquid to remove impurities from silicon and phosphorus, and then add calcium oxide to the vanadium-containing liquid after impurity removal to carry out calcification and vanadium precipitation reaction, and obtain vanadium by solid-liquid separation Calcium acid solid and vanadium precipitation mother liquor;

[0053] (2) Mix the calcium vanadate solid obtained in step (1) with oxalic acid evenly, add deionized water to prepare a reaction slurry, conduct a heating reaction at 80°C for 1 hour, and separate the solid and liquid after the reaction to obtain vanadyl oxalate solution and calcium oxalate solid ;

[0054] (3) adding a concentration of 450g / L sodium hydroxide aqueous solution to the vanady...

Embodiment 2

[0058] This embodiment provides a method for directly preparing vanadium oxides from a vanadium-containing liquid, the method comprising the following steps:

[0059] (1) Add calcium additives to the vanadium-containing liquid of sodium roasting-water leaching vanadium-containing liquid to remove impurities from silicon and phosphorus, and then add calcium oxide to the vanadium-containing liquid after impurity removal to carry out calcification and vanadium precipitation reaction, and obtain vanadium by solid-liquid separation Calcium acid solid and vanadium precipitation mother liquor;

[0060] (2) Mix the calcium vanadate solid obtained in step (1) with oxalic acid evenly, add deionized water to prepare a reaction slurry, conduct a heating reaction at 80°C for 1 hour, and separate the solid and liquid after the reaction to obtain vanadyl oxalate solution and calcium oxalate solid ;

[0061] (3) Adding a concentration of 500g / L sodium hydroxide aqueous solution to the vanady...

Embodiment 3

[0065] This embodiment provides a method for directly preparing vanadium oxides from a vanadium-containing liquid, the method comprising the following steps:

[0066] (1) Add calcium additives to the vanadium-containing liquid of sodium roasting-water leaching vanadium-containing liquid to remove impurities from silicon and phosphorus, and then add calcium oxide to the vanadium-containing liquid after impurity removal to carry out calcification and vanadium precipitation reaction, and obtain vanadium by solid-liquid separation Calcium acid solid and vanadium precipitation mother liquor;

[0067] (2) Mix the calcium vanadate solid obtained in step (1) with oxalic acid evenly, add deionized water to prepare a reaction slurry, conduct a heating reaction at 80°C for 1 hour, and separate the solid and liquid after the reaction to obtain vanadyl oxalate solution and calcium oxalate solid ;

[0068] (3) Adding a concentration of 550g / L potassium hydroxide aqueous solution to the van...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com