Method for simultaneously determining content of phosphorus, magnesium, iron, aluminum, silicon, calcium, titanium, manganese and strontium in phosphorite by adopting ICP-AES

An ICP-AES, iron-aluminum-silicon technology, applied in the field of analysis and testing, can solve problems such as large measurement errors and spectral line intensity changes, and achieve the effects of accurate results, strong anti-interference ability, and wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

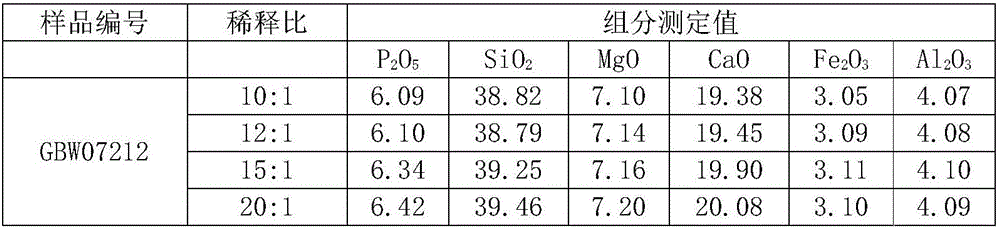

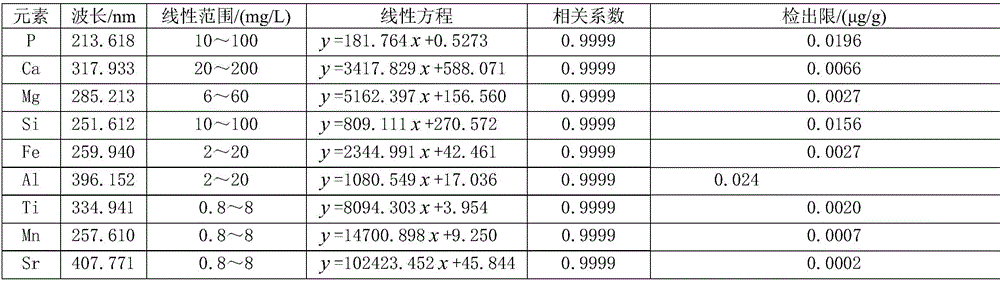

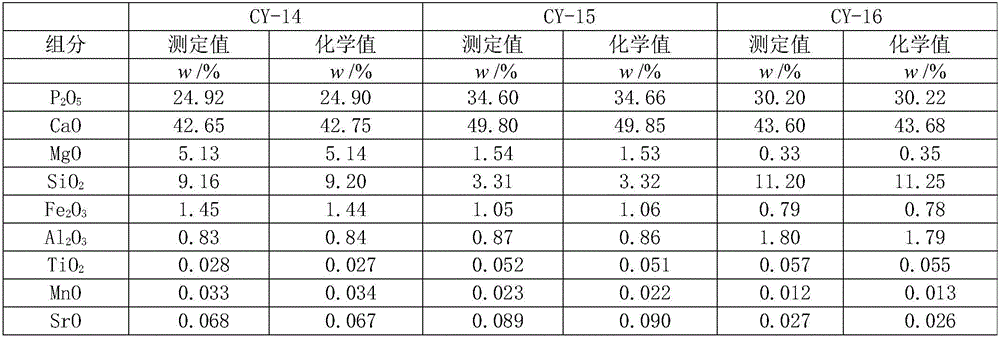

Examples

Embodiment Construction

[0019] The ICP-AES method is a method for simultaneously determining the content of phosphorus, magnesium, iron, aluminum, silicon, calcium, titanium, manganese, and strontium in phosphate rock. The equipment and instruments used: iCAP7400 full-spectrum direct-reading plasma emission spectrometer; hydrofluoric acid-resistant atomizer; Analymate-V4D high-frequency sample dissolution machine ,Specific steps are as follows:

[0020] a. Accurately weigh 0.1000g of phosphate rock sample and put it in a platinum crucible, add 1.2g of lithium metaborate and mix well, add 10 drops of lithium bromide solution, place it on a high-frequency sample dissolution machine, and pre-oxidize at 700°C for 2 minutes to fully oxidize the reduced product , then raise the temperature to 1050°C, and after melting for 2 minutes, take out the platinum crucible with crucible pliers, and immediately pour the red hot molten beads directly into a 400mL polytetrafluoroethylene beaker filled with 100mL nitric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com