Method for electrochemical detection of lead ions of ordered silicon nano-pore film/indium tin oxide electrode

A technology of indium tin oxide and silicon nanometers, applied in the direction of material electrochemical variables, etc., can solve the problems of cumbersome electrode pre-oxidation process and obstacles to popularization and application, and achieve high thermal and chemical stability, high sensitivity, and high porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Preparation of VOMs / ITO electrodes

[0051] (1) Precursor solution preparation: Weigh 0.16g CTAB, add 70ml deionized water and stir thoroughly, then add 30ml ethanol, 12μL ammonia water (20-25%), 80μL TEOS, and stir for 10min.

[0052] (2) CSMs / VOMs / ITO electrode preparation: Pour the precursor solution into the reactor and put the cleaned ITO electrode. The reactor was sealed and heated in a 60°C water bath for 24h. After the reaction was completed, the sample was washed with a large amount of deionized water, dried with nitrogen, and aged in an oven at 100°C for 12h.

[0053] (3) VOMs / ITO electrode preparation: put the CSMs / VOMs / ITO electrode in 0.1mol / L hydrochloric acid / ethanol solution, stir for 10min to remove the CTAB micelles in the electrode, and obtain the VOMs / ITO electrode.

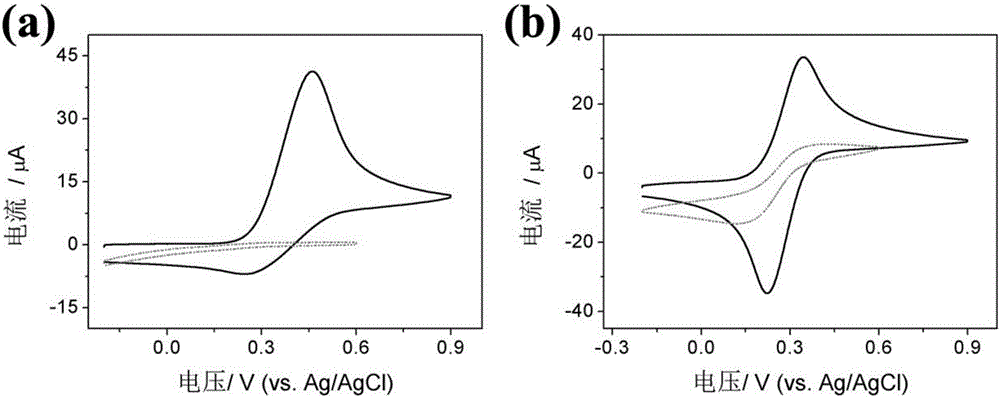

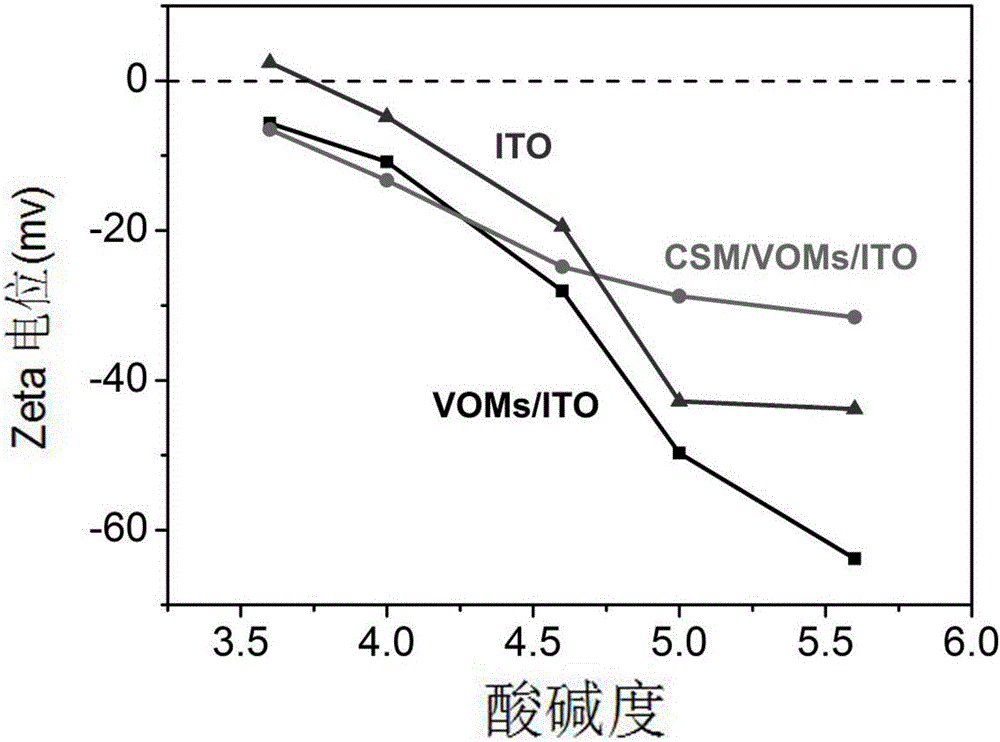

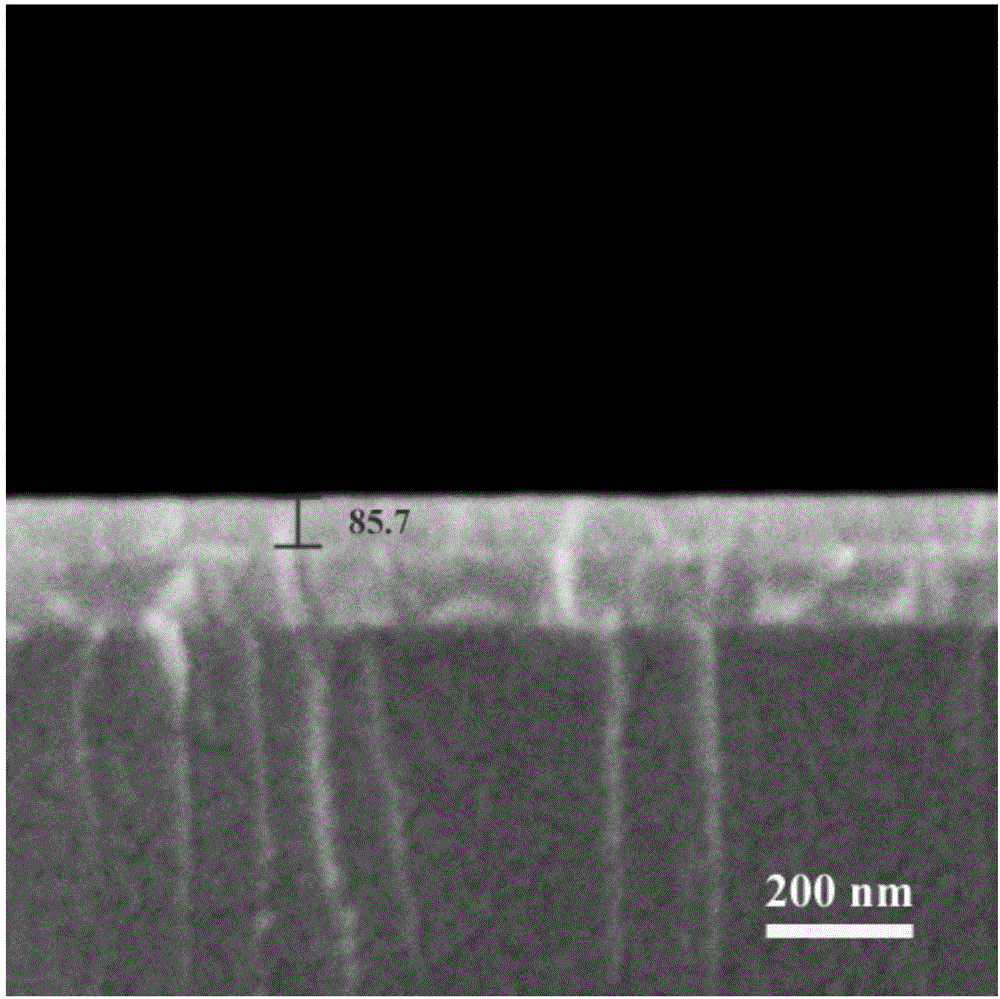

[0054] 2. Characterization

[0055] The VOMs / ITO electrode in Example 1 is characterized by electrochemical probes, Zeta potential, scanning electron microscopy, transmission elect...

Embodiment 2

[0073] The artificial lake water was diluted with pH 5.6 acetic acid-sodium acetate buffer at a ratio of 1:1, and 1nmol / L, 10nmol / L and 500nmol / L lead ion solutions were added using the standard addition method.

[0074] The VOMs / ITO electrode prepared in step 1 in Example 1 is used as the working electrode, the platinum electrode is the reference electrode, and Ag / AgCl is the reference electrode, and the above solutions are respectively added thereto, and the constant voltage is rich at -0.75V. Set of 420s. Then the electrode that has been enriched is washed with deionized water, and then the peak current intensity of different concentrations of lead ions is measured by differential pulse voltammetry (DPV), wherein the working parameters of differential pulse voltammetry: the initial potential is -0.75V , the termination potential is -0.2V.

[0075] Calculate lead ion concentration according to the working curve established in step 3 in Example 1, and then calculate the reco...

Embodiment 3

[0077] The separated human serum was diluted with pH 5.6 acetic acid-sodium acetate buffer at a ratio of 1:40, and 1 nmol / L, 10 nmol / L and 500 nmol / L lead ion solutions were added by standard addition method.

[0078] The VOMs / ITO electrode prepared in step 1 in Example 1 is used as the working electrode, the platinum electrode is the reference electrode, and Ag / AgCl is the reference electrode, and the above solutions are respectively added thereto, and the constant voltage is rich at -0.75V. Set of 420s. Then the electrode that has been enriched is washed with deionized water, and then the peak current intensity of different concentrations of lead ions is measured by differential pulse voltammetry (DPV), wherein the working parameters of differential pulse voltammetry: the initial potential is -0.75V , the termination potential is -0.2V.

[0079] Calculate lead ion concentration according to the working curve established in step 3 in Example 1, and then calculate the recover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com