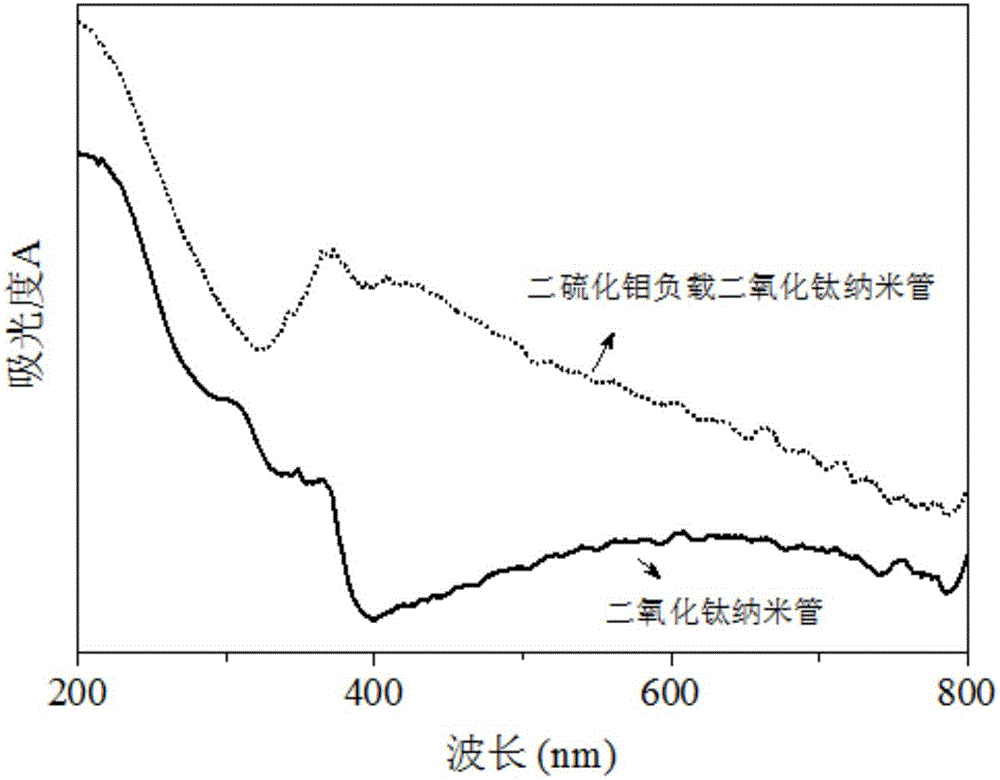

Visible light catalyst molybdenum disulfide loaded titanium dioxide nano-tube electrode as well as preparation method and application thereof

A technology of titanium dioxide and molybdenum disulfide, which is applied in the field of photocatalysis, can solve the problems of low utilization rate of visible light, low quantum efficiency and limitation, and achieve the effects of obvious visible light absorption performance, simple preparation process and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

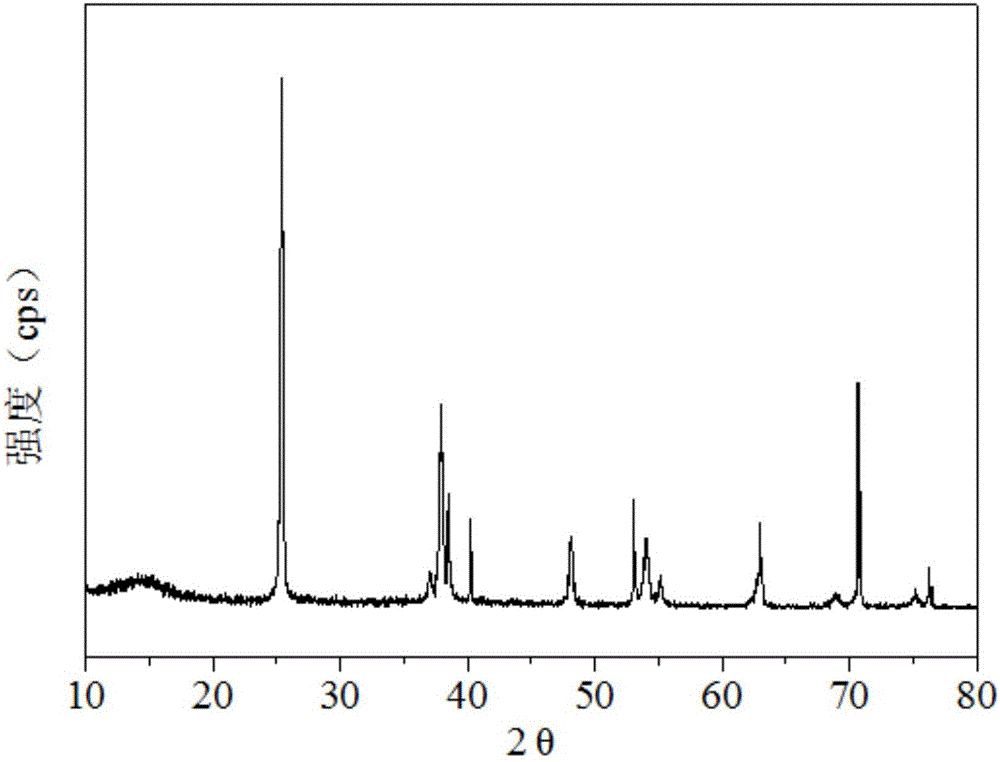

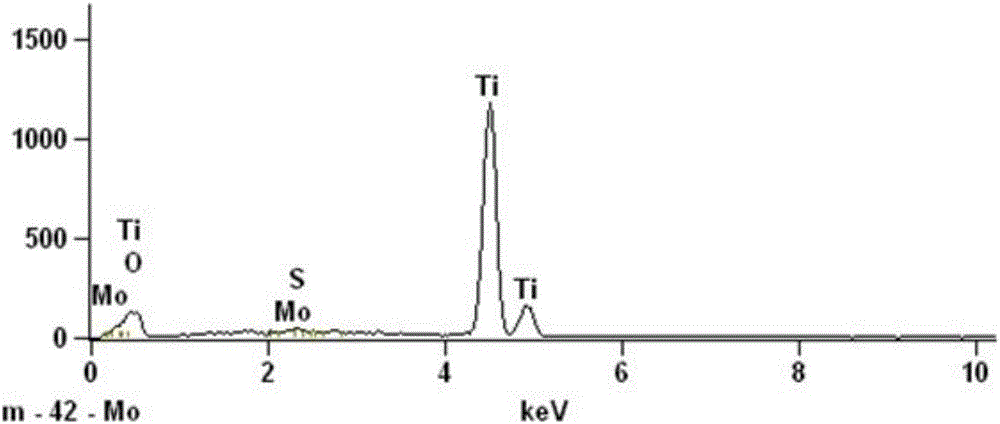

[0024] Example 1 Preparation of visible light catalyst molybdenum disulfide supported titanium dioxide nanotube electrode

[0025] Take 5ml HF and 20ml HNO 3 Dissolve in 25ml deionized water to obtain a mixed acid solution. The titanium sheets were polished to smooth with sandpaper of different meshes, the electrode sheets were etched in a mixed acid solution, and then ultrasonically cleaned by ethanol and deionized water respectively. Take 0.2g NH 4 F and 1.6ml of deionized water were dissolved in 78ml of ethylene glycol to obtain an anodized electrolyte. The titanium sheet is used as the working electrode, and the platinum sheet electrode is used as the counter electrode, respectively connected to the positive and negative poles of the DC power supply, and slowly pressurized to 60V. After anodic oxidation reaction at room temperature for 30 minutes, the titanium sheet is taken out, and the cleaned electrode is placed in the Naturally air-dried in the air, and calcined the...

Embodiment 2

[0027] Example 2 Preparation of visible light catalyst molybdenum disulfide supported titanium dioxide nanotube electrode

[0028] 1) Solution configuration: take 1mlHF and 4mlHNO 3 Dissolve in 5ml deionized water to obtain a mixed acid solution; take 0.1gNH 4 F and 0.5ml of deionized water were dissolved in 70ml of ethylene glycol to obtain an anodic oxidation electrolyte; 0.01g of ammonium tetrathiomolybdate and 0.05g of anhydrous sodium sulfate were dissolved in 40ml of deionized water, and nitrogen gas was continued for 10 -20 minutes, get rid of dissolved oxygen, and obtain electrodeposited electrolyte;

[0029] 2) Preparation of titania nanotube array electrodes: the titanium sheets were polished to smooth with sandpaper of different meshes, the polished titanium sheets were etched in a mixed acid solution, and then ultrasonically cleaned by ethanol and deionized water respectively, and then In the anodized electrolyte, the ultrasonically cleaned titanium sheet is used...

Embodiment 3

[0031] Example 3 Preparation of visible light catalyst molybdenum disulfide supported titanium dioxide nanotube electrode

[0032] 1) Solution configuration: take 10mlHF and 40mlHNO 3 Dissolve in 50ml deionized water to obtain a mixed acid solution; take 0.5gNH 4 F and 2ml of deionized water were dissolved in 90ml of ethylene glycol to obtain an anodized electrolyte; 0.013g of ammonium tetrathiomolybdate and 0.071g of anhydrous sodium sulfate were dissolved in 50ml of deionized water, and nitrogen gas was continuously passed for 10- 20 minutes, get rid of dissolved oxygen, obtain electrodeposition electrolyte;

[0033] 2) Preparation of titania nanotube array electrodes: the titanium sheets were polished to smooth with sandpaper of different meshes, the polished titanium sheets were etched in a mixed acid solution, and then ultrasonically cleaned by ethanol and deionized water respectively, and then In the anodized electrolyte, the ultrasonically cleaned titanium sheet is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com