Aromatization method

An aromatization and catalyst technology, applied in the field of aromatization, to achieve good selectivity and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

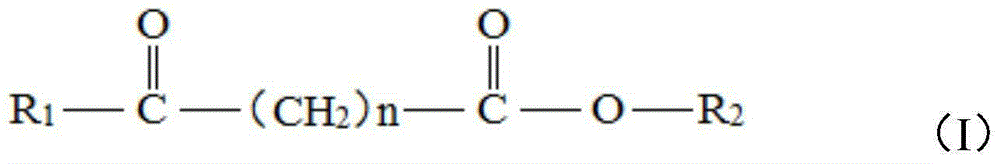

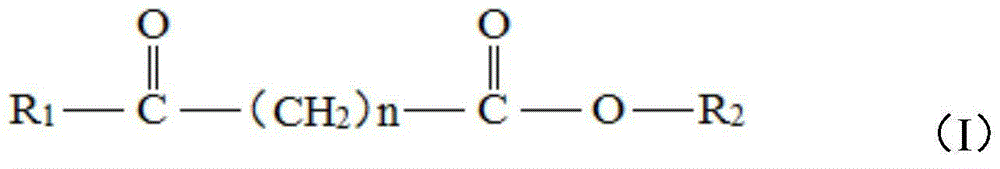

Method used

Image

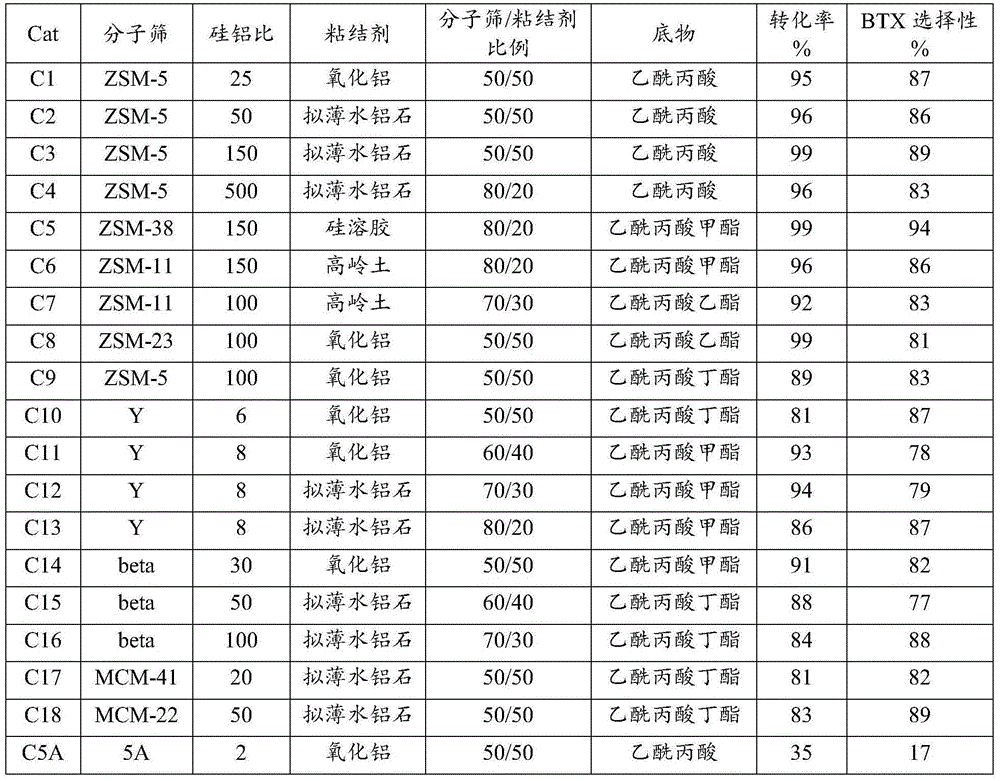

Examples

Embodiment 1

[0024] Weigh 60 grams of corn stalks, place in an autoclave and add 700 grams of water, then add a 5mol / L sulfuric acid solution with 7% water quality, heat up to 180°C and react for 45 minutes, then cool, and the cooled reaction solution Filtrate to obtain filter cake and filtrate, the filtrate is the hydrolyzate of cellulose, after the reaction, the mass spectrometry is used to identify the reaction result. The main product is levulinic acid, and its production amount is 18 grams.

[0025]Weigh 35 grams of ZSM-5 with a silicon-aluminum ratio of 25 and mix it with 35 grams of γ-alumina additive, add 2.7 grams of scallop powder, and mix well. Then add 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5%, knead and shape, and extrude. The obtained catalyst precursor was dried at 120° C. for 8 hours and calcined at 500° C. for 2 hours to obtain molecular sieve catalyst C1.

[0026] Catalyst activity evaluation is carried out on a fixed bed, the...

Embodiment 2

[0028] Weigh 35 grams of ZSM-5 with a silicon-aluminum ratio of 50 and mix them with 35 grams of pseudo-boehmite, add 2.7 grams of celadon powder, and mix well. Then add 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5%, knead and shape, and extrude. The obtained catalyst precursor was dried at 120° C. for 8 hours and calcined at 500° C. for 2 hours to obtain molecular sieve catalyst C2.

[0029] Catalyst activity evaluation is carried out on a fixed bed, the reaction conditions catalyst mass is 3 grams, the reaction substrate is levulinic acid, and the weight space velocity is 3.0 hours -1 , hydrogen pressure 1.0MPa, flow 50mlmin -1 , temperature 450°C. After the reaction, the conversion rate of the reaction substrate was 96%, and the selectivity of BTX was 86%.

Embodiment 3

[0031] Weigh 35 grams of ZSM-5 with a silicon-aluminum ratio of 150 and mix them with 35 grams of pseudo-boehmite, add 2.7 grams of safflower powder, and mix well. Then add 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5%, knead and shape, and extrude. The obtained catalyst precursor was dried at 120° C. for 8 hours and calcined at 500° C. for 2 hours to obtain molecular sieve catalyst C3.

[0032] Catalyst activity evaluation is carried out on a fixed bed, the reaction conditions catalyst mass is 3 grams, the reaction substrate is levulinic acid, and the weight space velocity is 2.5 hours -1 , hydrogen pressure 4.0MPa, flow 50mlmin -1 , temperature 550°C. After the reaction, the conversion rate of the reaction substrate was 99%, and the selectivity of BTX was 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com