Redispersible polyacrylic acid resin powder and preparation method thereof

A polyacrylic acid resin, redispersion technology, applied in the field of polyacrylic acid resin powder and its preparation, can solve the problems of safety risks, large sewage discharge, large water resources, etc., to avoid safety risks, reduce sewage discharge, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

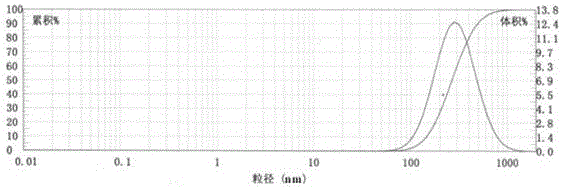

[0036] Add 180kg of water to a 300-liter enamel reaction kettle, then add 2.25kg of the emulsifier (Tween-80 and sodium lauryl sulfate in mass parts: 2:1), heat to 80°C under stirring, and then add the Potassium persulfide 0.2kg, then slowly add methacrylic acid-methyl methacrylate mixed solution 73.8kg (the mass ratio of methacrylic acid and methyl methacrylate is 50:50, including a small amount of chain transfer agent), in The addition was completed within 135 minutes. After the addition, the mixture was stirred at 85° C. for 2.5 hours, and then cooled to obtain a resin emulsion. Slowly add 2N sodium hydroxide solution to the prepared resin emulsion under stirring to partially neutralize the carboxylate. With the addition of sodium hydroxide solution, the viscosity of the material gradually increases until the viscosity of the material reaches 80mpa.s at 25°C stop adding sodium hydroxide solution. The partly neutralized resin emulsion was filtered through 80 mesh and then s...

Embodiment 2

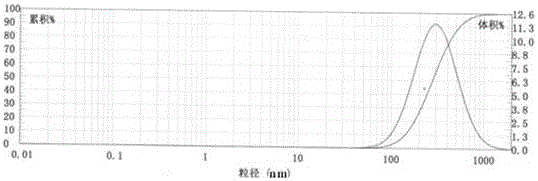

[0039] Add 180kg of water to a 300-liter enamel reaction kettle, then add 2.1kg of the emulsifier (Tween-80 and sodium lauryl sulfate in mass parts: 2:1), heat to 80°C under stirring, and then add the Ammonium persulfide 0.2kg, then slowly add 73.8kg of methacrylic acid-butyl acrylate mixture (the mass ratio of methacrylic acid to butyl acrylate is 35:65, including a small amount of chain transfer agent), within 135 minutes After the addition, continue to stir at 85°C for 2.5 hours, then cool to obtain a resin emulsion. Slowly add 2N sodium hydroxide solution to the prepared resin emulsion under stirring to partially neutralize the carboxylate groups. With the addition of sodium hydroxide solution, the viscosity of the material gradually increases until the viscosity of the material reaches 100mpa.s at 25°C stop adding sodium hydroxide solution. The partly neutralized resin emulsion was filtered through 80 mesh and then subjected to centrifugal spray drying. The air inlet tem...

Embodiment 3

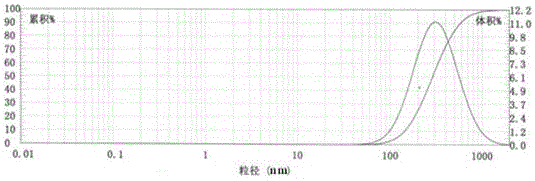

[0042] Add 180kg of water to a 300-liter enamel reaction kettle, then add 2.1kg of the emulsifier (Tween-80 and sodium lauryl sulfate in mass parts: 2:1), heat to 85°C under stirring, and then add the Potassium persulfide 0.2kg, then slowly add 73.8kg of methacrylic acid-ethyl acrylate mixture (the mass ratio of methacrylic acid to ethyl acrylate is 50:50, including a small amount of chain transfer agent), and add in 135 minutes After the addition, continue to stir at 85°C for 2.5 hours, then cool to obtain a resin emulsion. Slowly add 2N sodium hydroxide solution to the prepared resin emulsion under stirring to partially neutralize the carboxylate groups. With the addition of sodium hydroxide solution, the viscosity of the material gradually increases until the viscosity of the material reaches 100mpa.s at 25°C stop adding sodium hydroxide solution. The partly neutralized resin emulsion was filtered through 80 mesh and then subjected to centrifugal spray drying. The air inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com