Method for epitaxial growth of crack-free high-crystal-quality LED epitaxial layer on metal gallium nitride composite substrate

A composite substrate and crystal quality technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of poor thermal conductivity of sapphire substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Use Aixtron company, tightly coupled vertical reaction chamber MOCVD growth system. During the growth process of the LED epitaxial wafer structure, trimethylgallium (TMGa), triethylgallium (TEGa), trimethylindium (TMIn), trimethylaluminum (TMAl) were used as Group III sources, ammonia (NH 3 ) as Ga, Al, In and N sources respectively, with silane (SiH 4 ) as an n-type dopant, dimagnesocene (Cp 2 Mg) as a p-type dopant;

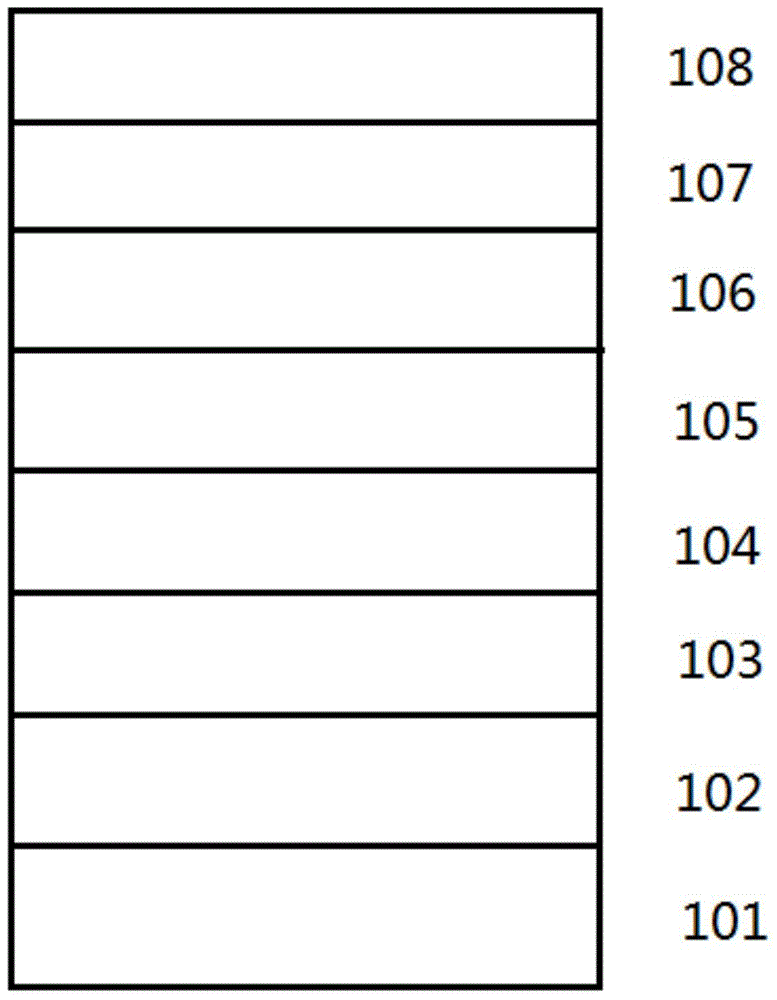

[0020] First in the metal organic compound vapor phase epitaxy reaction chamber the metal gallium nitride composite substrate (101), in nitrogen (N 2 ) atmosphere, the temperature was raised to 750-850°C for annealing treatment, and NH was slowly introduced into the reaction chamber after annealing treatment 3 , the NH 3 The flow rate increases sequentially: 1500sccm, 3000sccm, 6000sccm, 8000sccm, 10000sccm (sccm, standard cubic centimeter per minute, standard cubic centimeter per minute), and then slowly introduce TMGa, the pressure in the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com