Extraction process of high-purity phloridzin

An extraction process, phlorizin technology, applied in the field of phlorizin extraction, can solve problems such as difficult application and paralysis, and achieve the effects of reducing organic residues, solving environmental problems, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

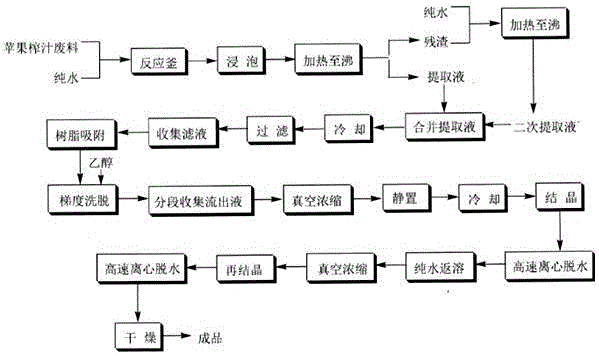

[0019] like figure 1 As shown, the high-purity phloridzin extraction process of the present invention comprises the following steps:

[0020] (1) Extraction of stock solution: add 8 times the pure water of apple juice with a water content of 3%, soak for 3 hours, heat to boiling, and keep slightly boiling for 2 hours to obtain an extract; the residue is heated with 6 times of pure water To boiling, keep slightly boiling for 2 hours to obtain secondary extracts. Combine the extracts, cool, filter, and collect the filtrate:

[0021] (2) Preliminary extraction of the finished product: the filtrate is adsorbed by the macroporous resin D101, the flow rate through the column is 80L / H, eluted with an ethanol gradient of 20°~50°, the effluent is collected in sections, concentrated in vacuo, allowed to stand, and cooled. , 0 ~ 4 ℃ to precipitate crystals, high-speed centrifugal dehydration;

[0022] (3) Finished product extraction: pure water redissolving, vacuum concentration, recry...

Embodiment 2

[0025] like figure 1 As shown, the high-purity phloridzin extraction process of the present invention comprises the following steps:

[0026] (1) Extraction of stock solution: add 8 times of pure water to the smashed bark, roots and branches and leaves of Rosaceae, soak for 3 hours, heat to boiling, and keep slightly boiling for 2 hours to obtain an extract; the residue uses 6 times of pure water The pure water was heated to boiling and kept slightly boiling for 2 hours to obtain a secondary extract. The extracts were combined, cooled, filtered, and the filtrate was collected:

[0027] (2) Preliminary extraction of the finished product: the filtrate is adsorbed by the macroporous resin D101, the flow rate through the column is 80L / H, eluted with an ethanol gradient of 20°~50°, the effluent is collected in sections, concentrated in vacuo, allowed to stand, and cooled. , 0 ~ 4 ℃ to precipitate crystals, high-speed centrifugal dehydration;

[0028] (3) Finished product extracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com