Fuel additive

A technology for additives and fuels, applied in the field of fuel additives, can solve problems such as unsatisfactory effects, and achieve the effects of reducing the generation of harmful gases and black smoke, fully burning fuel, and saving oil consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

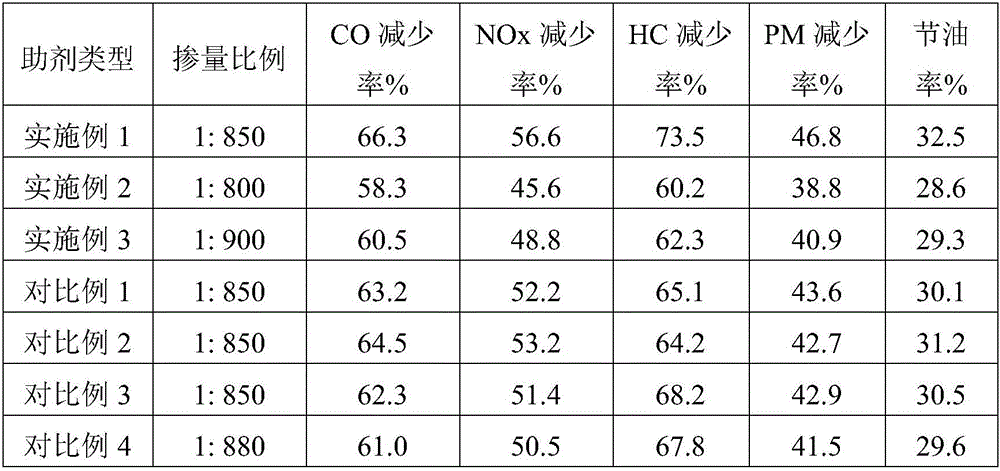

Examples

Embodiment 1

[0018] A fuel additive, made from the following components in proportions by weight: 4 parts of isobutanol, 3 parts of butenol, 2 parts of isopropyl ether, 5 parts of n-pentane, 12 parts of butyl acetate, chlorine 0.5 parts of paraffin wax, 8 parts of dicumyl peroxide, 6 parts of glycerin, 0.8 parts of ethyl acetate, 5 parts of fatty alcohol polyoxyethylene ether, 0.5 parts of octylphenol polyoxyethylene ether, 3 parts of polytetrafluoroethylene, 0.6 part of 2,6-di-tert-butyl-p-cresol, 0.5 part of perovskite catalyst, 0.2 part of shell powder, 2 parts of nano-cerium oxide, and 0.3 part of nano-magnesium powder.

[0019] The perovskite catalyst is composed of 3 parts of La 0.9 Sr 0.1 co 0.5 mn 0.5 o 3 , 2 copies of La 0.9 Na 0.1 co 0.5 mn 0.5 o 3 , 5 copies of LaVO 3 production.

[0020] The particle size of the polytetrafluoroethylene, perovskite catalyst and shell powder is 0.2 μm; the particle size of the nano-cerium oxide and nano-magnesium powder is 90 nm.

[0...

Embodiment 2

[0023] A fuel additive, made of the following components by weight: 3 parts of isobutanol, 2 parts of butenol, 1 part of isopropyl ether, 4 parts of n-pentane, 10 parts of butyl acetate, chlorine 0.3 parts of paraffin wax, 6 parts of dicumyl peroxide, 4 parts of glycerin, 0.6 parts of ethyl acetate, 3 parts of fatty alcohol polyoxyethylene ether, 0.2 parts of octylphenol polyoxyethylene ether, 2 parts of polytetrafluoroethylene, 0.4 part of 2,6-di-tert-butyl-p-cresol, 0.3 part of perovskite catalyst, 0.1 part of shell powder, 1 part of nano-cerium oxide, and 0.2 part of nano-magnesium powder.

[0024] The perovskite catalyst is composed of 2 parts of La 0.9 Sr 0.1 co 0.5 mn 0.5 o 3 , 1 La 0.9 Na 0.1 co 0.5 mn 0.5 o 3 , 4 copies of LaVO 3 production.

[0025] The particle size of the polytetrafluoroethylene, perovskite catalyst and shell powder is 0.1 μm; the particle size of the nano-cerium oxide and nano-magnesium powder is 80 nm.

[0026] Add directly to vehicle ...

Embodiment 3

[0028] A fuel additive, made from the following components in proportions by weight: 5 parts of isobutanol, 4 parts of butenol, 3 parts of isopropyl ether, 6 parts of n-pentane, 15 parts of butyl acetate, chlorine 0.6 parts of paraffin wax, 9 parts of dicumyl peroxide, 7 parts of glycerin, 0.9 parts of ethyl acetate, 6 parts of fatty alcohol polyoxyethylene ether, 0.7 parts of octylphenol polyoxyethylene ether, 4 parts of polytetrafluoroethylene, 0.9 parts of 2,6-di-tert-butyl-p-cresol, 0.7 parts of perovskite catalyst, 0.3 parts of shell powder, 3 parts of nano-cerium oxide, and 0.5 parts of nano-magnesium powder.

[0029] The perovskite catalyst is composed of 4 parts of La 0.9 Sr 0.1 co 0.5 mn 0.5 o 3 , 3 copies of La 0.9 Na 0.1 co 0.5 mn 0.5 o 3 , 6 copies of LaVO 3 production.

[0030] The particle size of the polytetrafluoroethylene, perovskite catalyst and shell powder is 0.2 μm; the particle size of the nano-cerium oxide and nano-magnesium powder is 100 nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com