Negative plate and lithium ion battery

A negative electrode sheet and negative electrode diaphragm technology, which is applied in the field of negative electrode sheets and lithium-ion batteries, can solve the problems of low tensile strength of electrolytic copper foil, poor electrical contact of negative electrode active materials, and reduced energy density, so as to improve electrical performance and Effects of cycle performance, stable electrochemical performance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

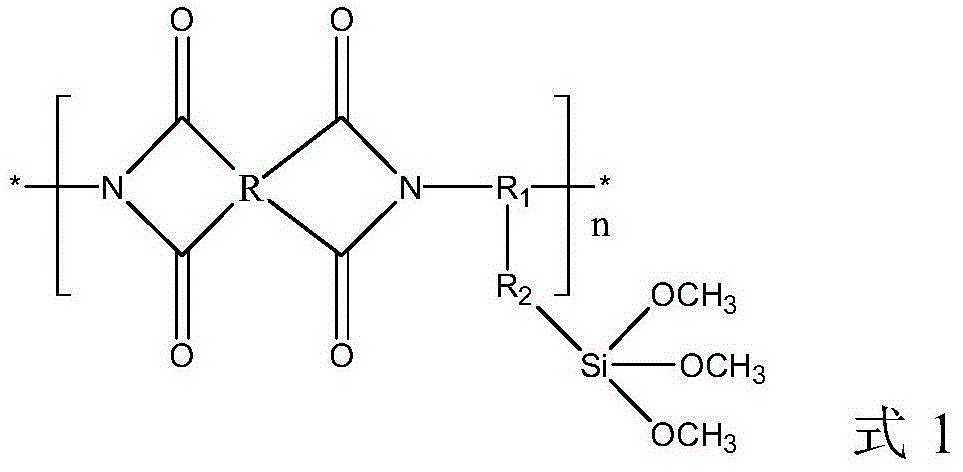

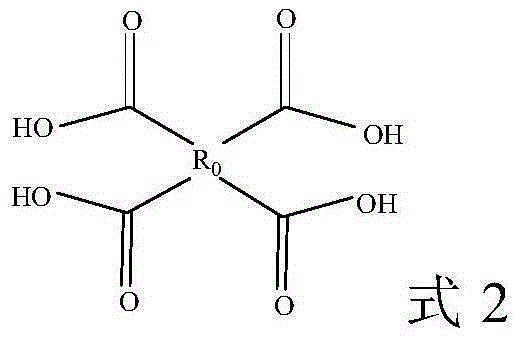

[0035] Next, the preparation method of the negative electrode sheet according to the second aspect of the present invention is described, which is used to prepare the negative electrode sheet described in the first aspect of the present invention, comprising the steps of: (1) combining tetraformic acid or tetraformic anhydride with dicarboxylic acid containing conductive polymer chains Amine siloxane is mixed as the precursor of the conductive binder and the negative electrode active material is dissolved in the solvent NMP and mechanically stirred to prepare a uniform fluid slurry; (2) The obtained fluid slurry is homogenized and coated on the negative electrode current collector In the above, the negative electrode current collector is rolled copper foil or stainless steel foil, followed by drying, heat treatment, cooling, rolling, and drying to complete the preparation of the negative electrode sheet.

[0036] In the method for preparing the negative electrode sheet accordin...

Embodiment 1

[0046] The negative electrode sheet was prepared according to the method of Comparative Example 2, except that the negative electrode current collector was rolled copper foil.

Embodiment 2

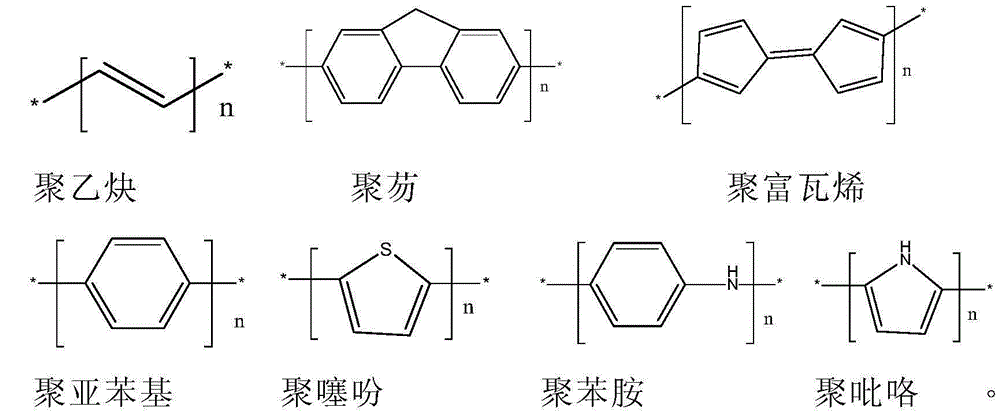

[0048] Negative electrode sheet was prepared according to the method of Comparative Example 2, the difference being: in formula 4, R 1 is phenyl, R 2 It is polyfulvalene, and the polymerization degree of polyfulvalene is 50; the negative current collector is rolled copper foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com