Carbon nanosphere/sulfur composite and preparation method and application thereof

A technology of carbon nanospheres and composite materials, applied in the field of nanomaterials and electrochemical energy, can solve the problems affecting battery energy density, battery capacity and low discharge platform, achieve enhanced physical adsorption, improve electrical activity, and facilitate rapid delivery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

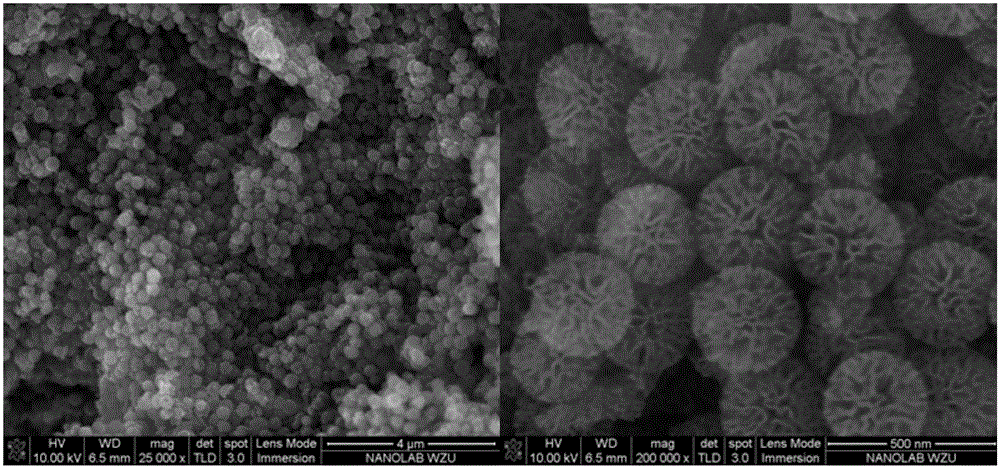

[0041] Step 2, preparation of nitrogen-doped hierarchical porous carbon nanospheres:

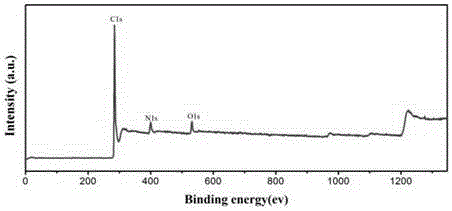

[0042] Weigh 1 g of chitosan and 0.5 g of the above-prepared silica nanospheres to mix, stir and dissolve in 150 mL of 2% acetic acid aqueous solution, then transfer to a 250 ml polytetrafluoroethylene hydrothermal reaction kettle, heat And keep it at 180°C for 12h, after cooling, filter, wash with water and ethanol successively, dry, heat treat at 800°C for 2h in argon atmosphere, add the obtained black powder into 10 mL of 20% hydrofluoric acid solution and stir, then Filtration and drying were performed sequentially to obtain nitrogen-doped hierarchical porous carbon nanospheres (FNCS) with a flower structure.

[0043] Summary: The mass ratio of the above variable chitosan to silica nanospheres is 2:1, which belongs to 1:1-4:1, and the heat treatment temperature under argon atmosphere is 800°C, which belongs to 700-900°C.

[0044] Step 3. Synthesis of nitrogen-doped hierarchical porous c...

Embodiment 1

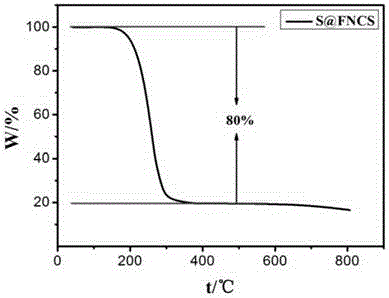

[0053] Take 0.08 g of the flower-shaped nitrogen-doped hierarchical porous carbon nanosphere (FCNS) sample prepared in step 2, mix with 0.42 g of sulfur powder, seal it, heat it in an oven at 160 ° C, cool it out after 10 hours, and obtain the flower shape Structural nitrogen-doped hierarchically porous carbon nanosphere / sulfur composites. According to the method in step 4, prepare electrodes and assemble batteries, and perform routine performance tests, the discharge capacity is 1005 mA h g at 1 C rate -1 .

Embodiment 2

[0055] Take 0.08 g of the flower-shaped nitrogen-doped hierarchical porous carbon nanosphere (FCNS) sample prepared in step 2, mix with 0.24 g of sulfur powder, seal it, heat it in an oven at 160 ° C, cool it for 10 hours, and take it out to obtain the flower shape Structural nitrogen-doped hierarchically porous carbon nanosphere / sulfur composites. According to the method in Example 1, the electrode and assembled battery were prepared, and the performance was routinely tested. The discharge capacity was 1100 mA h g at 1 C rate -1 .

[0056] Summary: Variables in Example 1, Example 2 and Step 3 are the proportion of sulfur in the composite material, which are 84wt%, 75wt% and 80wt% respectively, 84wt%, 75wt%, 80wt% and 70wt% of the prior art respectively Compared with that, the discharge capacity at 1C rate has been improved. The capacity is calculated based on the mass of sulfur. High content of sulfur is the pursuit of this research field, but if the content of sulfur is too...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com