Method for recycling acid liquor by utilizing aluminum-containing electric cast liquid and fluorine-containing wastewater

A technology for resource utilization and acid recovery, applied in aluminum fluoride, aluminum halide, electrolysis process, etc., can solve the problems of low energy consumption and high reaction efficiency, and achieve low energy consumption, high reaction efficiency, and no secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

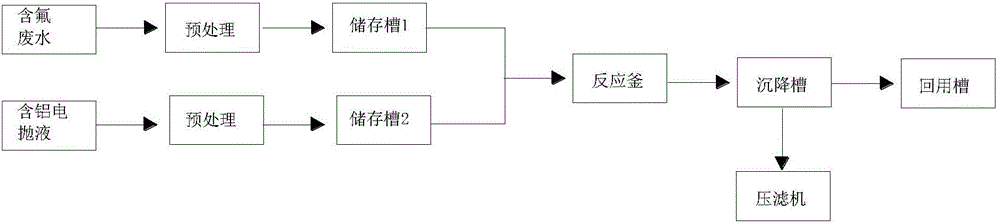

Image

Examples

Embodiment 1

[0034] Fluorine-containing wastewater: pre-treat the fluorine-containing wastewater produced by the smelting plant with quartz sand filtration to remove some large particles of impurities. The fluoride-containing wastewater mainly contains H + , F - , SO4 2- 、Na +Plasma. The pretreated fluorine-containing wastewater is stored in the storage tank 1 . A fluoride ion analyzer is installed in the storage tank 1 to detect the fluoride ion concentration, and the measurement result is 0.9g / L; the sodium ion concentration of the fluorine-containing wastewater in the storage tank 1 is detected, and the sodium ion meter is used for detection, and the measurement result is 0.7 g / L; the fluorine-containing wastewater in storage tank 1 is tested for sulfate ion, and the spectrophotometric method is used for detection, and the measurement result is 25g / L; the pH of the fluorine-containing wastewater in storage tank 1 is detected, and a pH meter is used for detection. The measurement res...

Embodiment 2

[0040] The pretreatment of fluorine-containing wastewater is the same as in Example 1.

[0041] The fluorine-containing waste water produced in the smelting plant is pretreated by quartz sand filtration, and the pretreated fluorine-containing waste water is stored in the storage tank 1 . The detection of the fluorine-containing wastewater in the storage tank 1 is as follows: the pH of the wastewater is 1.2; the concentration of fluoride ions is 1.1 g / L; the concentration of sodium ions is 0.8 g / L; the concentration of sulfate ions is 30 g / L.

[0042] The pretreatment of aluminum-containing electropolishing liquid is the same as in Example 1

[0043] The aluminum-containing electropolishing liquid is pretreated by quartz sand filtration and collected into storage tank 2, and aluminum ions in the electropolishing liquid in storage tank 2 are detected. The pH of the wastewater is 2; the concentration of aluminum ions is 33g / L; the concentration of phosphate ions is 15g / L; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com