Method for quickly starting CANON nitrogen removal process

A rapid start-up, NO2--N technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the problem of demanding seed sludge, slow start-up, and long start-up period and other problems, to achieve the effect of effectively cutting air bubbles, fast film formation, and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

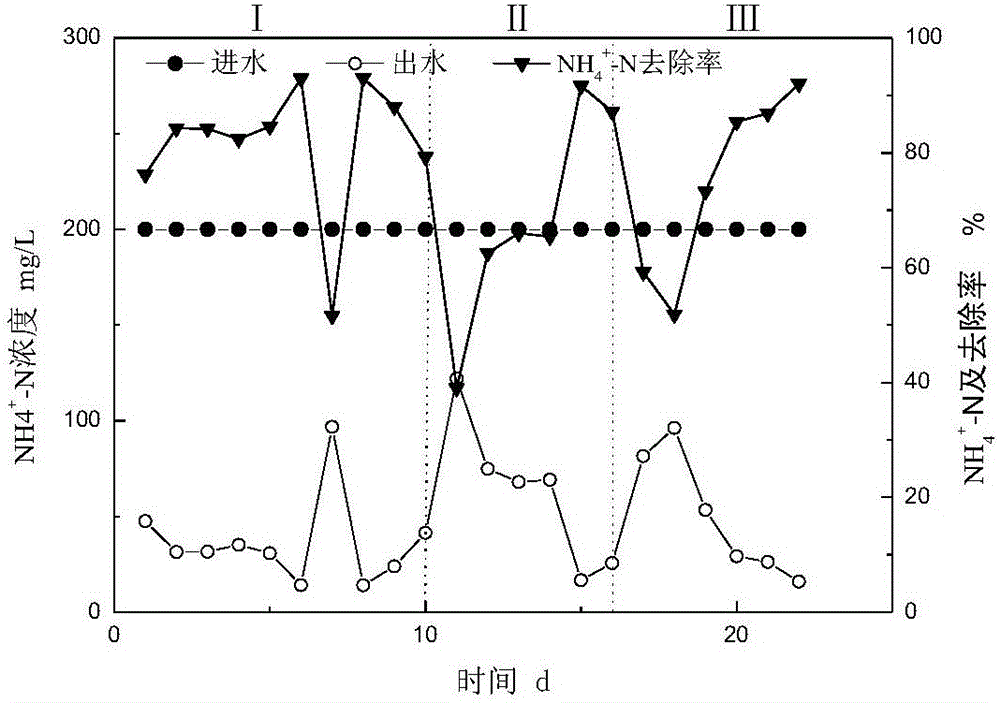

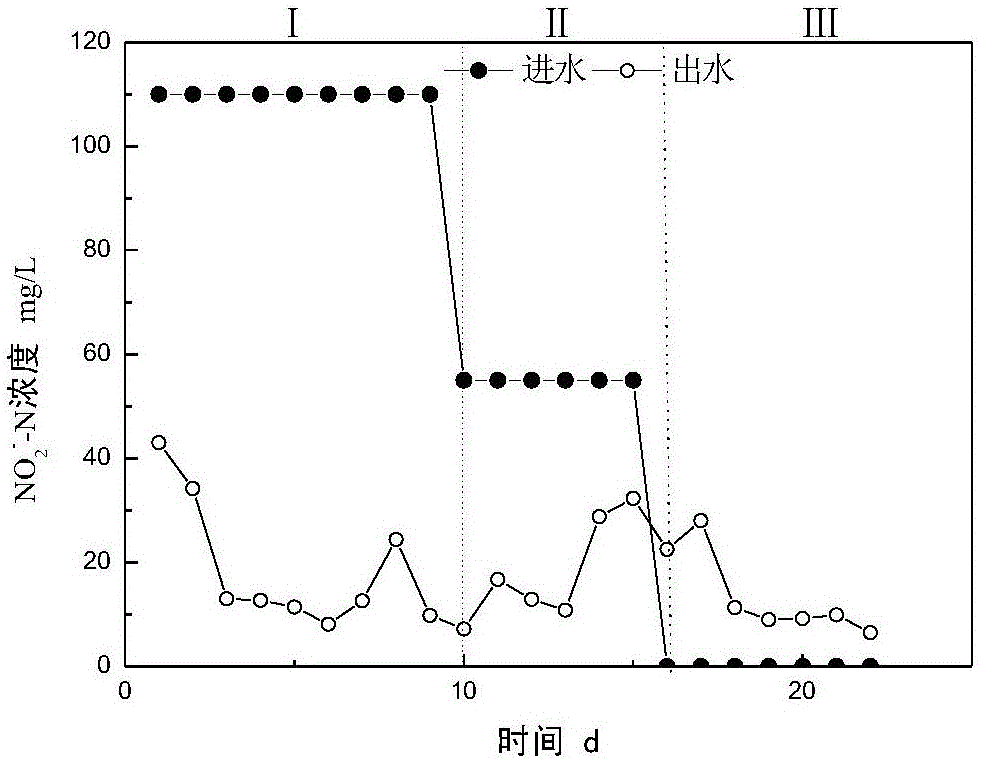

[0047] Activated sludge and anammox sludge were used as inoculation sludge for inoculation, in which the inoculation of anaerobic ammonium oxidation sludge was about 1L, and its MLSS was 9200mg / L. The activated sludge inoculation of domestic sewage is about 2L, and the MLSS is 6000mg / L. After the two sludges are mixed, they are added from the top of the reactor. The test water is artificially simulated carbon-free wastewater with high ammonia nitrogen, and the synthetic wastewater mainly provides NH 4 + -N, macro and trace elements for microbial growth and phosphorus, by addition of NaHCO 3 Adjust pH. NH 4 + -N concentration maintained at 200mg / L, NO 2 - -N concentration maintained at 0-110mg / L, NaHCO 3 The concentration is maintained at 1700mg / L, and argon gas is introduced into the water tank to mix evenly, and the dissolved oxygen in the water is removed at the same time.

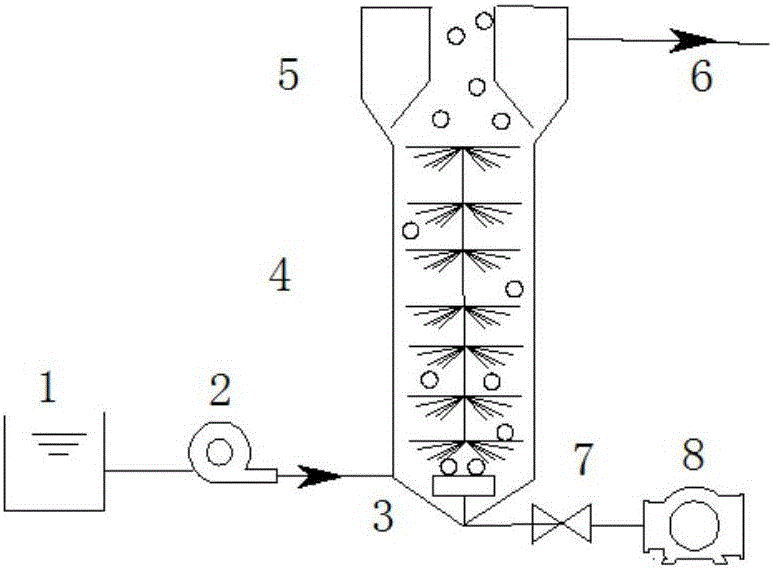

[0048] The reactor is made of plexiglass, mainly including a reaction zone and a three-phase...

Embodiment 2

[0053] Activated sludge and anammox sludge were used as inoculation sludge for inoculation, in which the inoculation of anaerobic ammonium oxidation sludge was about 1L, and its MLSS was 9200mg / L. The activated sludge inoculation of domestic sewage is about 2L, and the MLSS is 6000mg / L. After the two sludges are mixed, they are added from the top of the reactor. The test water is artificially simulated carbon-free wastewater with high ammonia nitrogen, and the synthetic wastewater mainly provides NH 4 +-N, macro and trace elements for microbial growth and phosphorus, by addition of NaHCO 3 Adjust pH. NH 4 + -N concentration maintained at 150mg / L, NO 2 - -N concentration maintained at 0-100mg / L, NaHCO 3 The concentration is maintained at 1700mg / L, and argon gas is introduced into the water tank to mix evenly, and the dissolved oxygen in the water is removed at the same time.

[0054] The reactor is made of plexiglass, mainly including a reaction zone and a three-phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com