Novel deep mercury removal process

A new type of advanced technology, applied in the field of industrial mercury-containing sewage treatment and deep mercury removal technology, can solve the problems of lack of mercury resources, environmental pollution, mercury resource depletion, etc., reduce the cost of sewage treatment, reduce environmental pollution, and have good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

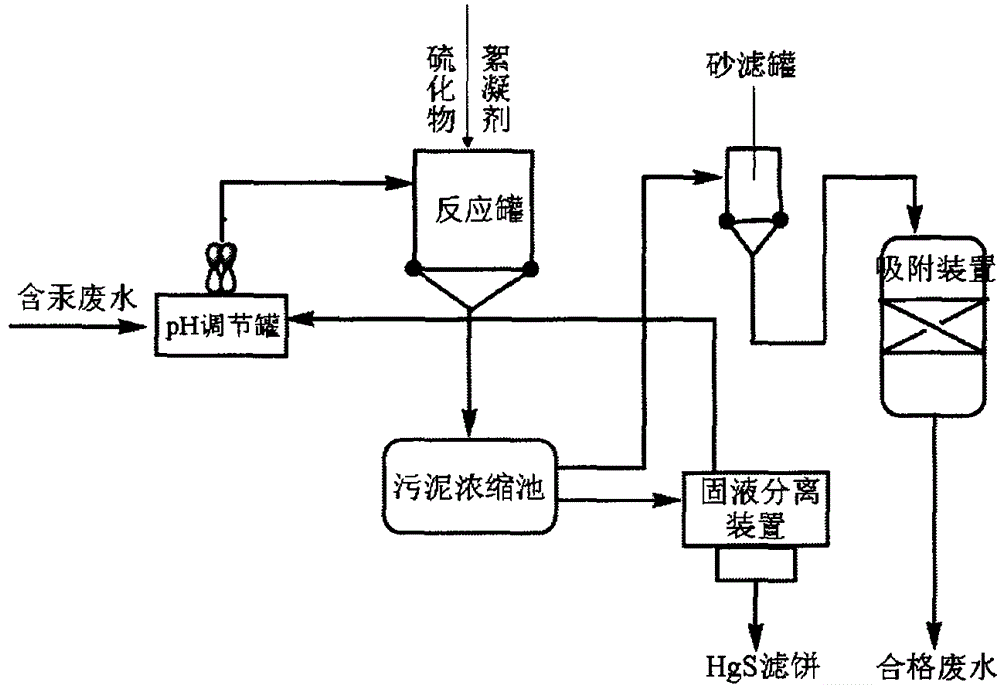

[0014] According to the attached figure 1 , the present embodiment comprises the following steps: filter the industrial mercury-containing waste water with a gauze to remove impurities such as floating matter and solid sediment, then collect it into a pH adjustment tank, use soda lime to adjust the pH value to 8.5, and remove calcium by filtration The mercury-containing waste liquid behind the slag is pumped into the reaction tank by the transfer pump, and sodium sulfide precipitant is added to the mercury-containing waste liquid in the obtained reaction tank at the same time, and the addition amount is 3 times of the mercury content in the waste liquid, and then the mass fraction is added. The composite ratio of 0.01% ferric chloride and polyaluminum chloride is 1:1 composite flocculant, and the addition amount is composite flocculant molar content: mercury molar content=0.5:1. In the flocculation process, polyacrylamide is added as a flocculant to improve the flocculation ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com