Preparation method of molecular sieve template high-purity hexamethonium hydroxide water solution

A technology of hexamethyldiammonium hydroxide and hexamethyldiammonium, which is applied in the direction of ammonium halide, electrolysis process, electrolysis components, etc., can solve the problems of poor product quality, residual silver ions, and high cost of precious metal raw materials, so as to improve service life and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of molecular sieve template agent high-purity hexamethonium hydroxide aqueous solution includes the following steps: (1) 112g (1mol) of 1,6-hexamethylenediamine is dissolved in 168g of water to prepare a 40% aqueous solution, which is added dropwise into a 2L reaction bottle In the mixture of 405g (5mol) of 37% formaldehyde solution and 281g (6mol) of 98% formic acid; stir, reheat, react at 80°C~100°C for 24 hours, add 288g (7mol) of 97% sodium hydroxide to adjust the pH value to 12~14, separate layers, take the organic layer, rectify under reduced pressure, vacuum degree -0.098MPa, remove the front fraction, collect the fraction at 120°C~140°C, and obtain 99% tetramethylhexyl Diamine 172g, the yield reaches more than 99%. (2) Weigh 172g (1mol) of tetramethylhexamethylenediamine dissolved in 80g (2.5mol) of methanol and 246g (6mol) of acetonitrile, add it to a 1L pressure reactor, and feed 111g (2.2mol) of methyl chloride, At a reaction temperatu...

Embodiment 2

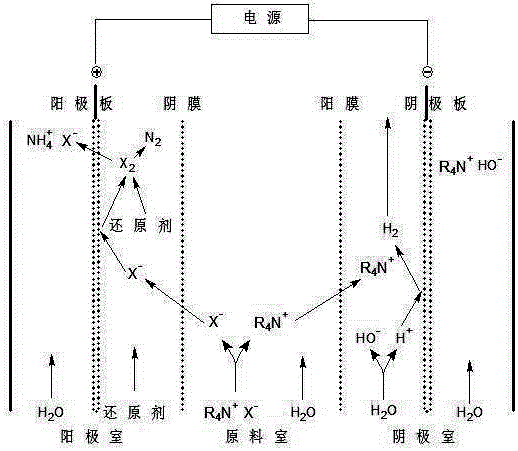

[0023]The preparation method of the molecular sieve template agent high-purity hexamethonium hydroxide aqueous solution comprises the following steps: (1) The preparation of tetramethylhexamethylenediamine is the same as in Example 1. (2) Weigh a mixture of 172g (1mol) of tetramethylhexamethylenediamine dissolved in 80g (2.5mol) of methanol and 246g (6mol) of acetonitrile, add it to a 1L pressure reactor, and feed 208g (2.2mol) of methyl bromide into the At a reaction temperature of 100°C and a pressure of 0.05MPa, the reaction was continued for 48 hours, cooled to 0-5°C, centrifuged, the solvent was recovered and applied mechanically, and the solid was dried at 80°C for 4 hours to obtain 357g of hexamethyldiammonium bromide, with a yield of about 98.62% . (3) Hexamethyldiammonium bromide is dissolved in pure water and enters the raw material room of the three-cavity two-membrane electrolyzer, the three-cavity two-membrane electrolyzer, the anode plate is a titanium substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com