Circulating oil supply system of strip tidying machine

A circulating oil supply and slitting machine technology, applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve problems such as lubricating oil splash, tea quality and health and safety impact, achieve stable oil supply, and improve recycling rate , The effect of facilitating timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

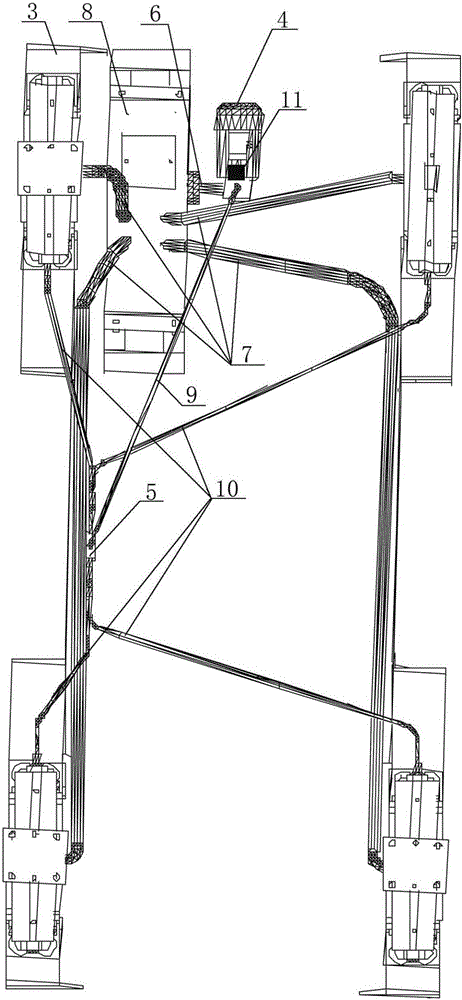

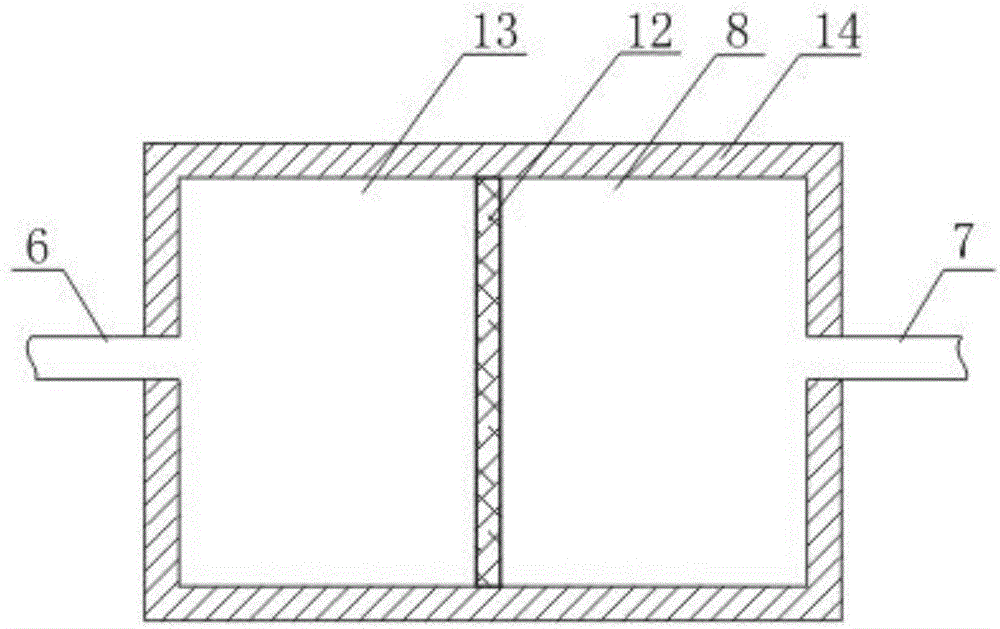

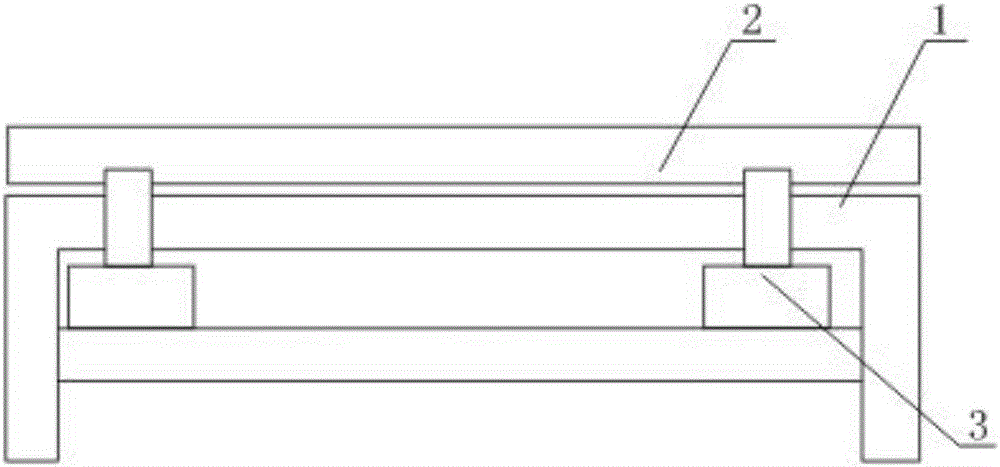

[0028] A cyclic oil supply system for a slitting machine, comprising a frame 1, a slitting groove plate 2 arranged on the frame 1, a slider box 3 for driving the slitting groove plate 2 to swing is arranged in the frame 1, the slider box 3 is provided with a circulating oil supply system; the circulating oil supply system includes a circulating pump 4, a collector 5, an oil outlet pipe 6, an oil return pipe 7, and an oil tank 8 for supplying oil to the slider box 3, and one end of the oil return pipe 7 is connected to the slider box 3, the other end is connected to the oil tank 8, one end of the oil outlet pipe 6 is connected to the oil tank 8, and the other end is connected to the circulation pump 4, the oil outlet of the circulation pump 4 is connected to the main oil pipe 9, and the main oil pipe 9 is connected to the collector 5 , the collector 5 is provided with a plurality of oil distribution pipes 10, the oil distribution pipes 10 are respectively connected with the slid...

Embodiment 2

[0030] On the basis of Embodiment 1, this embodiment also includes a controller electrically connected to the circulation pump 4, and an oil quantity sensor 11 is provided at the oil outlet of the circulation pump 4, and the oil quantity sensor 11 is connected to the controller for signal connection.

Embodiment 3

[0032]On the basis of Embodiment 2, this embodiment further includes an alarm, and the alarm is connected to the controller for signal connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com