Processing technology for purifying pollutants in hard-shelled seawater shellfish

A processing technology and pollutant technology, which is applied in the field of seafood purification and processing technology, can solve the problems of difficulty in controlling the effective concentration and uniformity of ozone, decreased biological activity of purified products, and high detection cost, and achieves obvious removal effect and no toxic side effects. , the effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

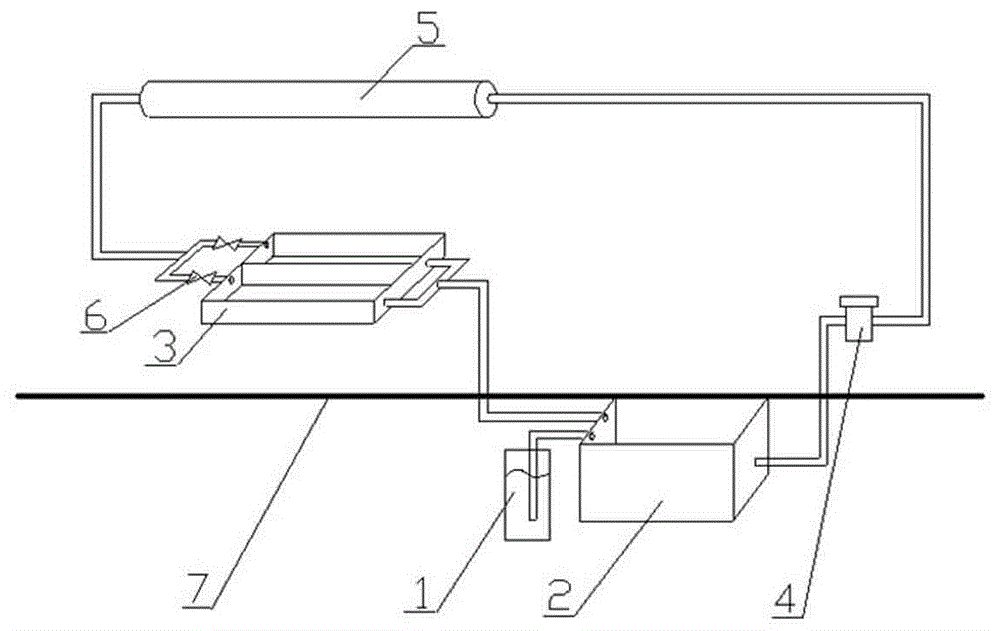

Image

Examples

Embodiment 1

[0033] According to the process requirements of the present invention, in a 12-ton / sub-scale shellfish purification plant constructed by the Jiaozhou Bay in Qingdao, Shandong, 12 tons of local Philippine clams were used for purification. After 24hr, the coliform content in the shellfish was 11000MPN / 100g shellfish meat drops to 90MPN / 100g, without any sediment.

Embodiment 2

[0035] According to the process requirements of the present invention, in a 2 ton / sub-scale shellfish purification plant constructed in Xiamen, Fujian, 2 tons of local cockles were taken for purification. After 24 hours, the coliform content in the shellfish decreased from 6000MPN / 100g shellfish. To <30MPN / 100g, without any sediment.

Embodiment 3

[0037] According to the process requirements of the present invention, in a shellfish purification plant with a scale of 5 tons / sub-scale constructed in Nantong, Jiangsu, 3 tons of local clams and 2 tons of green clams were taken for purification. After 24 hours, the coliform content of the clams was 2400MPN / 100g Shell meat drops to <30MPN / 100g, Vibrio parahaemolyticus changes from positive to negative without any sediment; the coliform content of green clams drops from 1900MPN / 100g to <30MPN / 100g, Vibrio parahaemolyticus changes from positive to negative without any sediment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com