Amino acid foaming cleansing gel and preparation method thereof

An amino acid, cleansing technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve problems such as hazards and many chemical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

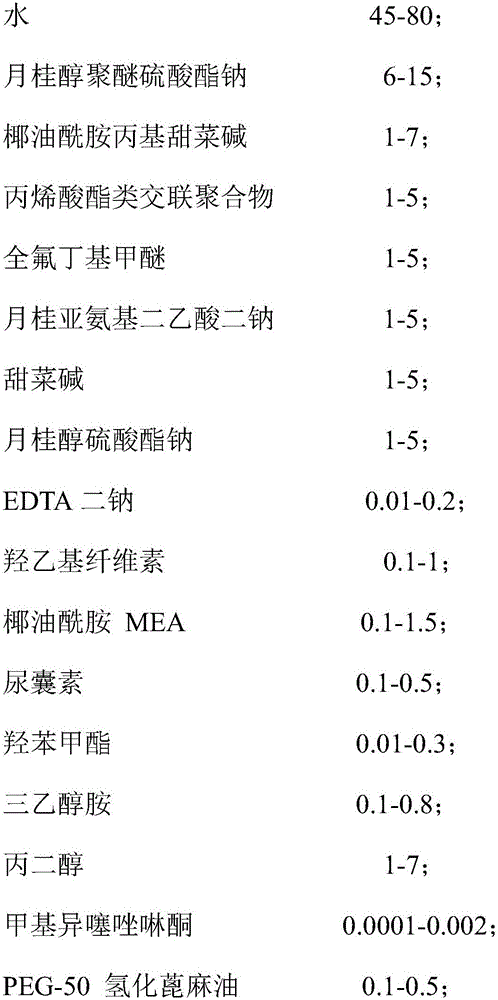

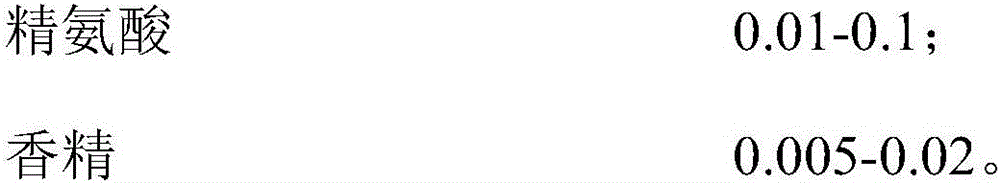

Method used

Image

Examples

Embodiment 1

[0027] Preparation of solvent: Clean the main pot and the oil pot of the emulsification pot; add 68.69wt% water to the main emulsification pot, add 0.5wt% hydroxyethyl cellulose to the water swirl, and homogenize until there is no particle agglomeration. use;

[0028] Preparation of auxiliary materials: Take 2wt% perfluorobutyl methyl ether, 3.2wt% disodium lauryl iminodiacetate, 0.005wt% essence and 0.15wt% PEG-50 hydrogenated castor oil and stir the material until it is evenly dispersed, and the stirring speed is 20 rpm minutes, standby;

[0029] Add major ingredients: add 9.5wt% sodium laureth sulfate, 1wt% betaine, 3wt% sodium lauryl sulfate, 0.15wt% disodium EDTA, 0.154wt% allantoin, 0.1wt% hydroxyl Benzyl ester, 3wt% propylene glycol and 0.05wt% arginine, start heating; heat to 85°C, add 1wt% cocamide MEA, stir and dissolve evenly; stir at 25 rpm, turn on cooling water to cool down, cool down When it reaches 60°C, add 3wt% cocamidopropyl betaine and 4wt% acrylate cross...

Embodiment 2

[0031] Preparation of solvent: Clean the main pot and the oil pot of the emulsification pot; add 63.57wt% water into the main emulsification pot, add 0.8wt% hydroxyethyl cellulose to the water swirl, homogenize until there is no particle agglomeration, wait until use;

[0032] Preparation of auxiliary materials: Take 3wt% perfluorobutyl methyl ether, 3.6wt% disodium lauryl iminodiacetate, 0.008wt% essence and 0.1wt% PEG-50 hydrogenated castor oil and stir the materials until they are evenly dispersed, and the stirring speed is 20 rpm minutes, standby;

[0033] Add major ingredients: add 10wt% sodium laureth sulfate, 2wt% betaine, 3.4wt% sodium lauryl sulfate, 0.08wt% disodium EDTA, 0.161wt% allantoin, 0.05wt% hydroxyl Benzyl ester, 4.3wt% propylene glycol and 0.03wt% arginine, start heating; heat to 85°C, add 0.8wt% cocamide MEA, stir and dissolve evenly; stirring speed is 25 rpm, turn on cooling water to cool down , when cooling down to 60°C, add 4.2wt% cocamidopropyl betai...

Embodiment 3

[0035] Preparation of solvent: Clean the main pot and the oil pot of the emulsification pot; add 66.09wt% water into the main emulsification pot, add 0.62wt% hydroxyethyl cellulose to the water swirl, and homogenize until there is no particle agglomeration. use;

[0036] Preparation of auxiliary materials: Take 1.8wt% perfluorobutyl methyl ether, 2.7wt% disodium lauryl iminodiacetate, 0.008wt% essence and 0.134wt% PEG-50 hydrogenated castor oil and stir the material until it is evenly dispersed, and the stirring speed is 20 rpm / min, standby;

[0037] Add major ingredients: add 12wt% sodium lauryl ether sulfate, 1.2wt% betaine, 4wt% sodium lauryl sulfate, 0.134wt% disodium EDTA, 0.163wt% allantoin, 0.07wt% hydroxyl Benzyl ester, 2wt% propylene glycol and 0.01wt% arginine, start heating; be heated to 85 ℃, add 0.86wt% cocamide MEA, stir and dissolve evenly; Stirring speed is 25 rev / min, open cooling water and cool down, When cooling down to 60°C, add 4.1wt% cocamidopropyl bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com