Denitration and mercury removal catalyst for coal-fired flue gas, method for preparing denitration and mercury removal catalyst and application thereof

A coal-fired flue gas and catalyst technology, applied in the field of resources and the environment, can solve the problems of easy shedding of active components, high catalytic activity, and high cost, and achieve the effects of enhancing catalytic oxidation ability, increasing specific surface area, and increasing oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

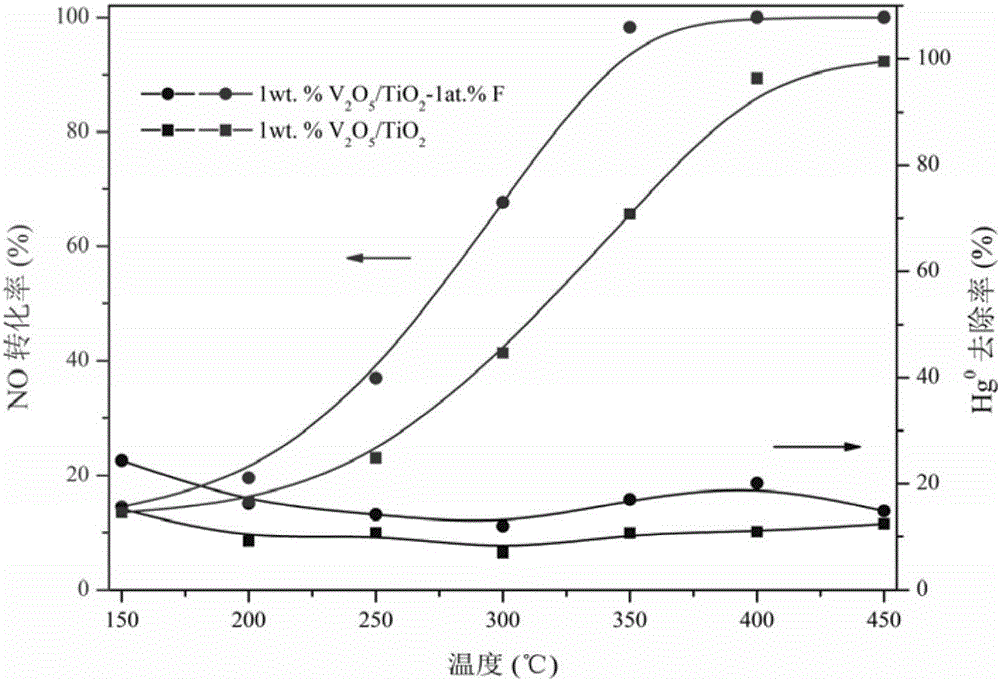

[0058] A carrier F-doped alum-based catalyst for simultaneous denitrification and demercuration of coal-fired flue gas (i.e. figure 1 1wt.% V expressed in 2 o 5 / TiO 2 -1at.%F), including a carrier and an active component, the carrier is F-doped titanium dioxide, and the active component is V 2 o 5 , the specific surface of the catalyst is 68m 2 / g, the active ingredient V 2 o 5 The mass of F is 1wt.% of the mass of the catalyst, and the molar weight of F is 1 at.% of the molar weight of titanium dioxide.

[0059] The preparation method of described catalyst specifically comprises the following steps:

[0060] (1) Add tetra-n-butyl titanate (C 16 h 36 o 4 Ti) (molar ratio is 1:1), form titanium source solution after stirring; Ammonium hexafluorotitanate H 8 f 6 N 2Ti is dissolved in water and mixed with absolute ethanol to form a fluoride salt solution, wherein the ammonium hexafluorotitanate (H 8 f 6 N 2 Ti) and tetra-n-butyl titanate (C 16 h 36 o 4 The mo...

Embodiment 2

[0070] A carrier F-doped alum-based catalyst for simultaneous denitrification and mercury removal of coal-burning flue gas, including a carrier and an active component, the carrier is F-doped titanium dioxide, and the active component is V 2 o 5 , the specific surface of the catalyst is 80m 2 / g, the active ingredient V 2 o 5 The mass of F is 2wt.% of the mass of the catalyst, and the molar weight of F is 2.0 at.% of the molar weight of titanium dioxide.

[0071] The preparation method of described catalyst specifically comprises the following steps:

[0072] (1) Add tetra-n-butyl titanate (C 16 h 36 o 4 Ti) (molar ratio is 1:1), form titanium source solution after stirring; Ammonium hexafluorotitanate H 8 f 6 N 2 Ti is dissolved in water and mixed with absolute ethanol to form a fluoride salt solution, wherein the ammonium hexafluorotitanate (H 8 f 6 N 2 Ti) and tetra-n-butyl titanate (C 16 h 36 o 4 The molar ratio of Ti) is 2:100 respectively, and tetra-n-buty...

Embodiment 3

[0077] A carrier F-doped alum-based catalyst for simultaneous denitrification and mercury removal of coal-burning flue gas, including a carrier and an active component, the carrier is F-doped titanium dioxide, and the active component is V 2 o 5 , the specific surface of the catalyst is 60m 2 / g, the active ingredient V 2 o 5 The quality of F is 1.5wt.% of the mass of the catalyst, and the molar weight of F is 1 at.% of the molar weight of titanium dioxide.

[0078] The preparation method of described catalyst specifically comprises the following steps:

[0079] (1) Add tetra-n-butyl titanate (C 16 h 36 o 4 Ti) (molar ratio is 2:1), form titanium source solution after stirring; Ammonium hexafluorotitanate H 8 f 6 N 2 Ti is dissolved in water and mixed with absolute ethanol to form a fluoride salt solution, wherein the ammonium hexafluorotitanate (H 8 f 6 N 2 Ti) and tetra-n-butyl titanate (C 16 h 36 o 4 The molar ratio of Ti) is 1:100 respectively, and tetra-n-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com