A kind of method for preparing silicon fertilizer from industrial waste residue

A technology of industrial waste residue and silicon fertilizer, which is applied in agriculture, fertilization device, fertilizer mixture, etc., to achieve the effect of fast heating rate, improvement of acid soil, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

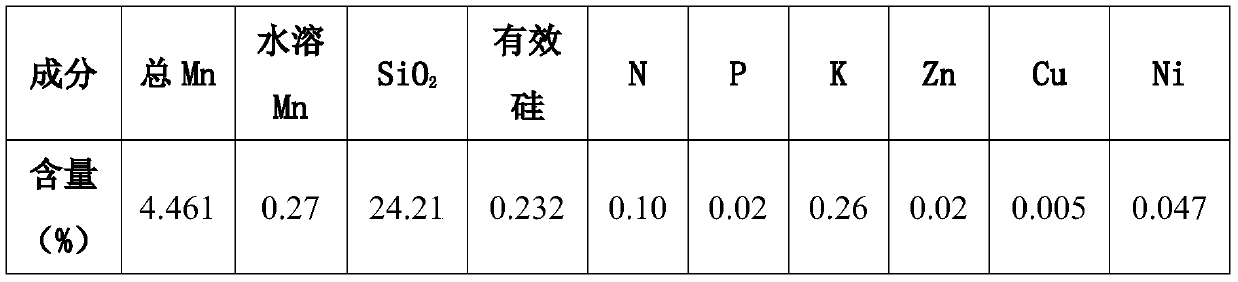

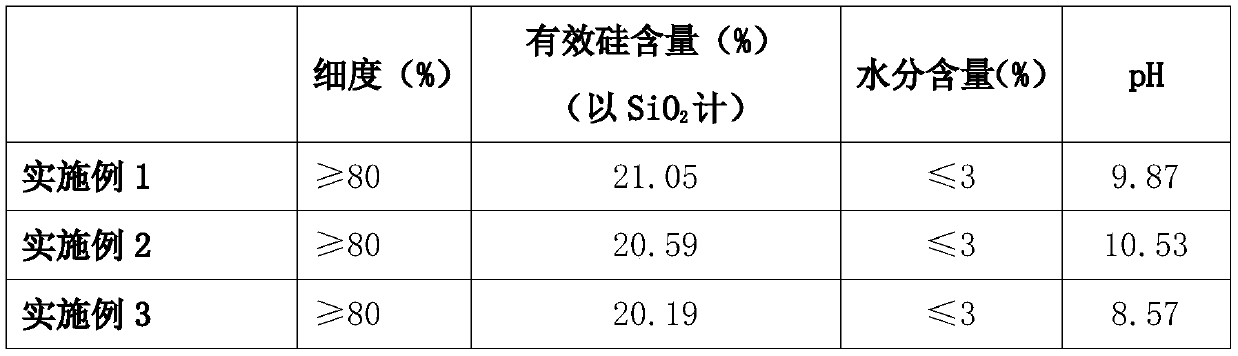

[0028] A method for preparing silicon fertilizer from industrial waste residues: adding electrolytic manganese slag, fly ash, sodium carbonate, and sodium hydroxide into a planetary ball mill at a ratio of 1:0.4:0.6:0.1, with a ball-to-material ratio of 5g / g, and a rotational speed of 150r / min, the ball milling time is 20min for mixing, put the mixed material into the porcelain boat, put it into the microwave high-temperature sintering furnace, the calcination temperature is 800 ℃, and the calcination time is 30min; after crushing, the fineness (by 250μm standard Sieve) ≥ 80%, effective silicon (as SiO 2 Silicon fertilizer products with a content of 21.05%, a pH of 9.87, and a moisture content of ≤3%.

[0029] The method for measuring the pH of silicon fertilizers is: NY / T 1377-2007 Determination of soil pH.

Embodiment 2

[0032] A method for preparing silicon fertilizer from industrial waste residues: adding electrolytic manganese slag, fly ash, sodium carbonate, and sodium hydroxide into a planetary ball mill at a ratio of 1:0.3:0.4:0.1, with a ball-to-material ratio of 8g / g and a rotational speed of 200r / min, the ball milling time is 40min for mixing, then put the mixed material into a porcelain boat, put it into a microwave high-temperature sintering furnace, the calcination temperature is 850°C, and the calcination time is 10min; after crushing, the fineness (through 250μm Standard sieve) ≥ 80%, effective silicon (as SiO 2 Silicon fertilizer products with a content of 20.59%, a pH of 10.53, and a moisture content of ≤3%.

Embodiment 3

[0034] A method for preparing silicon fertilizer from industrial waste residues: adding electrolytic manganese slag, fly ash, sodium carbonate, and sodium hydroxide into a planetary ball mill at a ratio of 1:0.5:0.5:0.1, with a ball-to-material ratio of 10g / g and a rotational speed of 250r / min, the ball milling time is 60min for mixing, then put the mixed material into a porcelain boat, put it into a microwave high-temperature sintering furnace, the calcination temperature is 750°C, and the calcination time is 60min; after crushing, the fineness (through 250μm Standard sieve) ≥ 80%, effective silicon (as SiO 2 A silicon fertilizer product with a content of 20.19%, a pH of 8.57, and a moisture content of ≤3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com