Zr/chitosan composite adsorbent for adsorbing Pb<2+> in water body and preparation method thereof

A composite adsorption and chitosan technology, applied in the fields of adsorption water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of chemical promotion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

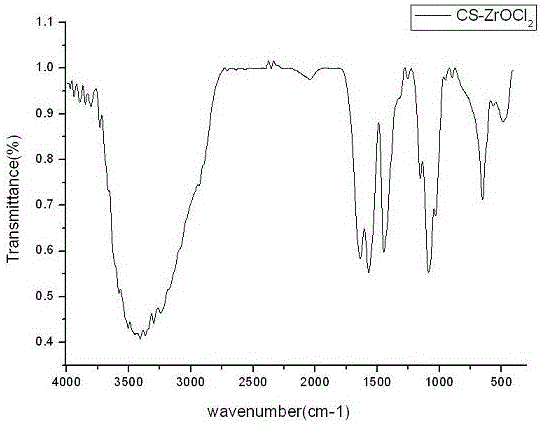

Image

Examples

preparation example Construction

[0024] The first aspect of the present invention provides a method for adsorbing Pb in water 2+ The preparation method of Zr / chitosan composite adsorbent, comprises the following steps:

[0025] (1) Preparation of chitosan colloid: dissolving chitosan in acetic acid solution, stirring and sonicating to prepare chitosan colloid;

[0026] (2) Preparation of zirconium oxychloride solution: dissolving zirconium oxychloride octahydrate in deionized water to prepare zirconium oxychloride solution;

[0027] (3) Mix the chitosan colloid described in step (1) with the zirconium oxychloride solution described in step (2), stir and sonicate to obtain a uniformly dispersed mixed solution;

[0028] (4) Cross-linking reaction: adding aldehyde to the mixed solution described in step (3), stirring, drying and grinding to obtain the Zr / chitosan composite adsorbent.

[0029] In the step (1) of the embodiment of the present invention, the stirring time for preparing the chitosan colloid is 2-4...

Embodiment 1

[0048]Weigh 1.0 g of chitosan, dissolve it in 36 mL of 2% acetic acid solution, stir at room temperature for 3 h, and then sonicate for 30 min to obtain chitosan colloid; weigh 0.8 g of zirconium oxychloride octahydrate and disperse it in 10 mL of deionized water , stirred at room temperature for 3 hours, and ultrasonicated for 30 minutes to obtain a zirconium oxychloride solution; pour the zirconium oxychloride solution into the chitosan colloid, stirred at room temperature for 24 hours, and then ultrasonicated for 1 hour to make it fully mixed to obtain a uniformly dispersed mixed solution; 4.6 mL of glutaraldehyde solution with a volume ratio of 1% was added dropwise to the mixed solution of zirconium oxychloride and chitosan colloid, stirred for 1 h to cause a cross-linking reaction, and then dried in an oven at 55 °C for 36 h to obtain dry The Zr / chitosan composite material is ground, and the Zr / chitosan composite material is ground to obtain a powdery Zr / chitosan composit...

Embodiment 2

[0051] Weigh 1.0g of chitosan, dissolve it in 36mL of 2% acetic acid solution, stir at room temperature for 3h, and then sonicate for 30min to obtain chitosan colloid; weigh 1.6g of zirconium oxychloride octahydrate and disperse it in 10mL of deionized water, Stir at room temperature for 3 hours, and sonicate for 30 minutes to obtain a zirconium oxychloride solution; pour the zirconium oxychloride solution into chitosan colloid, stir at room temperature for 24 hours, and then sonicate for 1 hour to make it fully mixed to obtain a uniformly dispersed mixed solution; 4.6 mL of glutaraldehyde solution with a ratio of 1% was added dropwise to the mixed solution of zirconium oxychloride and chitosan colloid, stirred for 1 h to cause a cross-linking reaction, and then dried in an oven at 55 °C for 36 h to obtain dry Zr / chitosan composite material, grinding the above Zr / chitosan composite material to obtain powdered Zr / chitosan composite adsorbent.

[0052] Use Pb with an initial con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com