Preparation method of bio-char composite adsorbing material for removing phosphates in surface water

A composite adsorption material and bio-carbon technology, applied in water pollutants, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as difficult operation, secondary pollution, and high operating costs, and achieve low cost and economical savings Cost, the effect of improving carbonization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

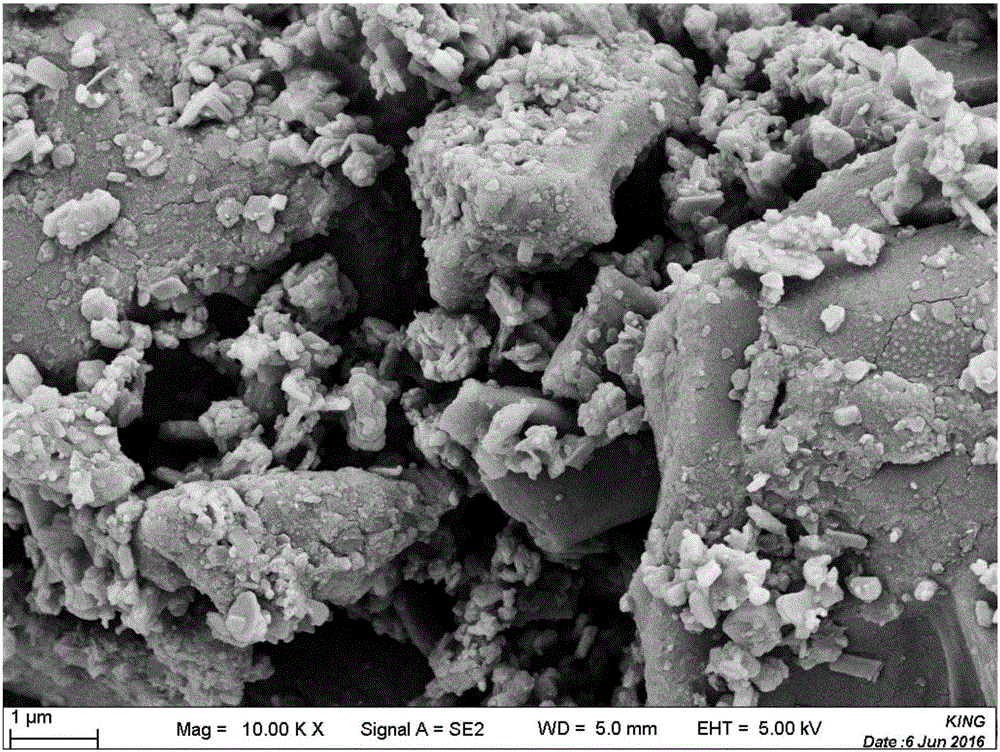

Embodiment 1

[0040] The pomelo peel was washed, air-dried and cut, then heated and pyrolyzed in an anoxic environment in a muffle furnace at a temperature of 350°C and a pyrolysis time of 30 minutes. The pyrolyzed material was cooled and then added to 1.2mol / L FeSO 4 solution, shaken for 60 minutes. Filtrate and collect the carbonized biomass solids, add the cleaned carbonized biomass solids to 0.1mol / L Na 2 S 2 o 3 solution, shaken for 40 minutes. After the solid was collected by filtration, it was added to a CTMAB solution containing 0.03 mol / L, shaken for 50 minutes, filtered and washed with deionized water until neutral, and baked at 80° C. for 6 hours, which was the biological carbonaceous composite adsorption material 1.

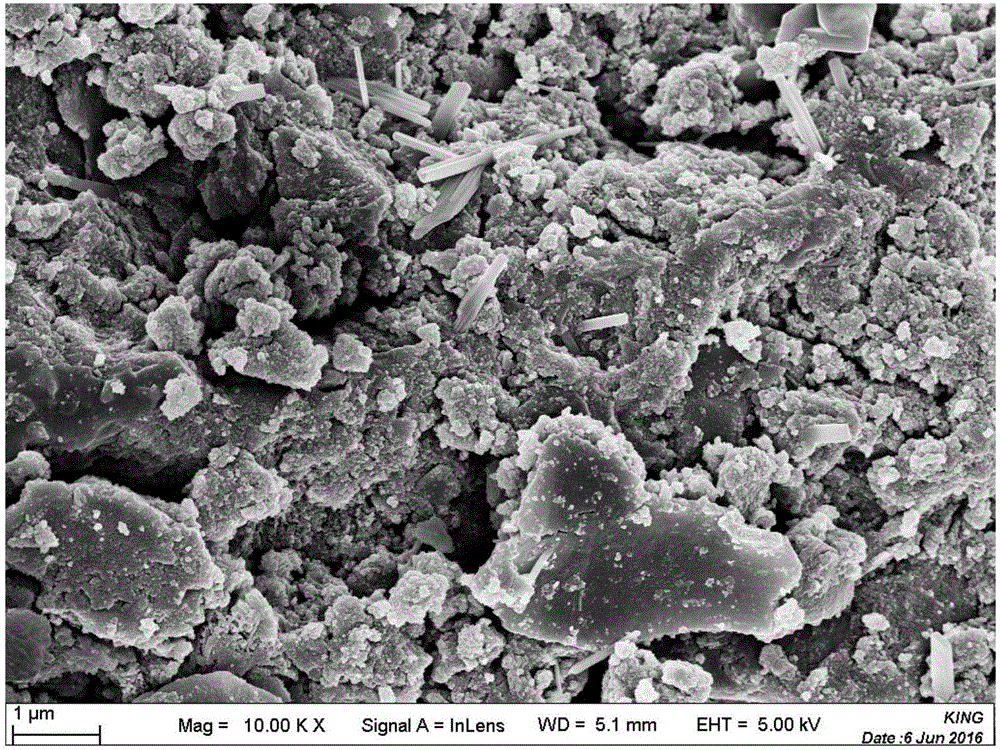

Embodiment 2

[0042] The orange peels were washed, air-dried and cut, then heated and pyrolyzed in a muffle furnace in an oxygen-deficient environment with a pyrolysis temperature of 350°C and a pyrolysis time of 30 minutes. The pyrolyzed material was cooled and then added to 1.2mol / L FeSO 4 solution, shaken for 60 minutes. Filtrate and collect the carbonized biomass solids, add the cleaned carbonized biomass solids to 0.1mol / L Na 2 S 2 o 3 solution, shaken for 40 minutes. After the solid was collected by filtration, it was added to the CTMAB solution containing 0.03 mol / L, shaken for 50 minutes, filtered and washed with deionized water until neutral, and baked at 100°C for 5 hours, which was the biological carbonaceous composite adsorption material 2.

Embodiment 3

[0044] After washing and air-drying the grapefruit peels and orange peels, heat and pyrolyze them in an oxygen-free environment in a muffle furnace. The pyrolysis temperature is 450° C. and the pyrolysis time is 20 minutes. The material after pyrolysis is cooled, and the grapefruit peel and orange peel are mixed according to the mass ratio of 9:1, and then added to 1.5mol / L FeSO 4 solution, shaken for 60 minutes. Filter and collect carbonized biomass solids, add the cleaned carbonized biomass solids to 0.3mol / L Na 2 S 2 o 3 solution, shaken for 40 minutes. After the solid was collected by filtration, it was added to a 0.03 mol / L CTMAB solution, shaken for 50 minutes, filtered and washed with deionized water until neutral, and baked at 100° C. for 5 hours, which was the biological carbonaceous composite adsorption material 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com