Hybrid fiber reinforced polypropylene composite material

A composite material and hybrid fiber technology, which is applied in the field of hybrid fiber reinforced polypropylene composite materials, can solve the problems of poor tensile strength and toughness, and achieve good high temperature wear resistance, high elastic modulus, and good room temperature wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

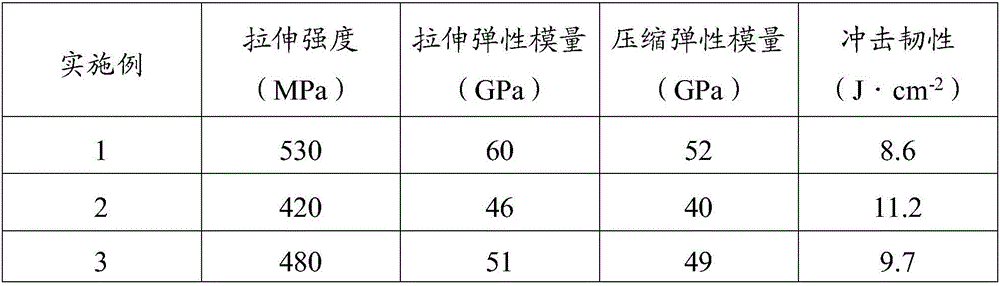

Examples

Embodiment 1

[0025] The invention discloses a hybrid fiber-reinforced polypropylene composite material, which comprises the following components in terms of mass fraction:

[0026] 10% glass fiber, 50% carbon fiber, 2% aramid fiber, 5% bamboo fiber, 5% basic magnesium sulfate whisker, 10% polypropylene, 5% functional polypropylene copolymer, 3% epoxy resin, binder 2%, filler 8%.

[0027] The binder is 1 wt% of nitrile modified phenolic resin and 1 wt% of rubber powder, and the filler is a mixture of pyrophyllite powder, barium sulfate, potassium feldspar and kyanite.

[0028] The glass fiber is a continuous alkali-free glass fiber with a diameter of 15-30 μm, the polypropylene is a homopolypropylene; the functional polypropylene copolymer is a polypropylene / polyvinylpyrrolidone block copolymer, which melts The index is 2.8-7.5g / min under the test conditions of 230°C and 2.16Kg, and the mass percentage of polyvinylpyrrolidone in the functional polypropylene copolymer is 60%.

Embodiment 2

[0030] The invention discloses a hybrid fiber-reinforced polypropylene composite material, which comprises the following components in terms of mass fraction:

[0031] Glass fiber 30%, carbon fiber 10%, aramid fiber 5%, bamboo fiber 10%, basic magnesium sulfate whisker 10%, polypropylene 15%, functional polypropylene copolymer 5%, epoxy resin 5%, binder 3%, filler 7%.

[0032] Described binder is the nitrile modified phenolic resin of 2wt% and the rubber powder of 1wt%, and described filler is pyrophyllite powder, barium sulfate, potassium feldspar, kyanite, aluminum oxide, iron oxide, graphite powder. mixture.

[0033] The glass fiber is a continuous alkali-free glass fiber with a diameter of 15-30 μm, and the polypropylene is a copolymerized polypropylene; the functional polypropylene copolymer is a polypropylene / polyvinylpyrrolidone block copolymer, and its melt index Under the test conditions of 230° C. and 2.16 Kg, it is 2.8-7.5 g / min, and the mass percent content of po...

Embodiment 3

[0035] The invention discloses a hybrid fiber-reinforced polypropylene composite material, which comprises the following components in terms of mass fraction:

[0036] 20% glass fiber, 20% carbon fiber, 5% aramid fiber, 7% bamboo fiber, 13% basic magnesium sulfate whisker, 11% polypropylene, 3% functional polypropylene copolymer, 6% epoxy resin, binder 8%, filler 7%.

[0037] The binder is 5wt% nitrile modified phenolic resin and 3wt% rubber powder, and the filler is a mixture of pyrophyllite powder, barium sulfate, potassium feldspar, aluminum oxide and iron oxide.

[0038] The glass fiber is a continuous alkali-free glass fiber with a diameter of 15-30 μm, and the polypropylene is a mixture of homopolypropylene and copolymerized polypropylene; the functional polypropylene copolymer is polypropylene / polyvinylpyrrolidone embedded The segment copolymer has a melt index of 2.8-7.5g / min under the test conditions of 230°C and 2.16Kg, and the polyvinylpyrrolidone mass percentage i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com